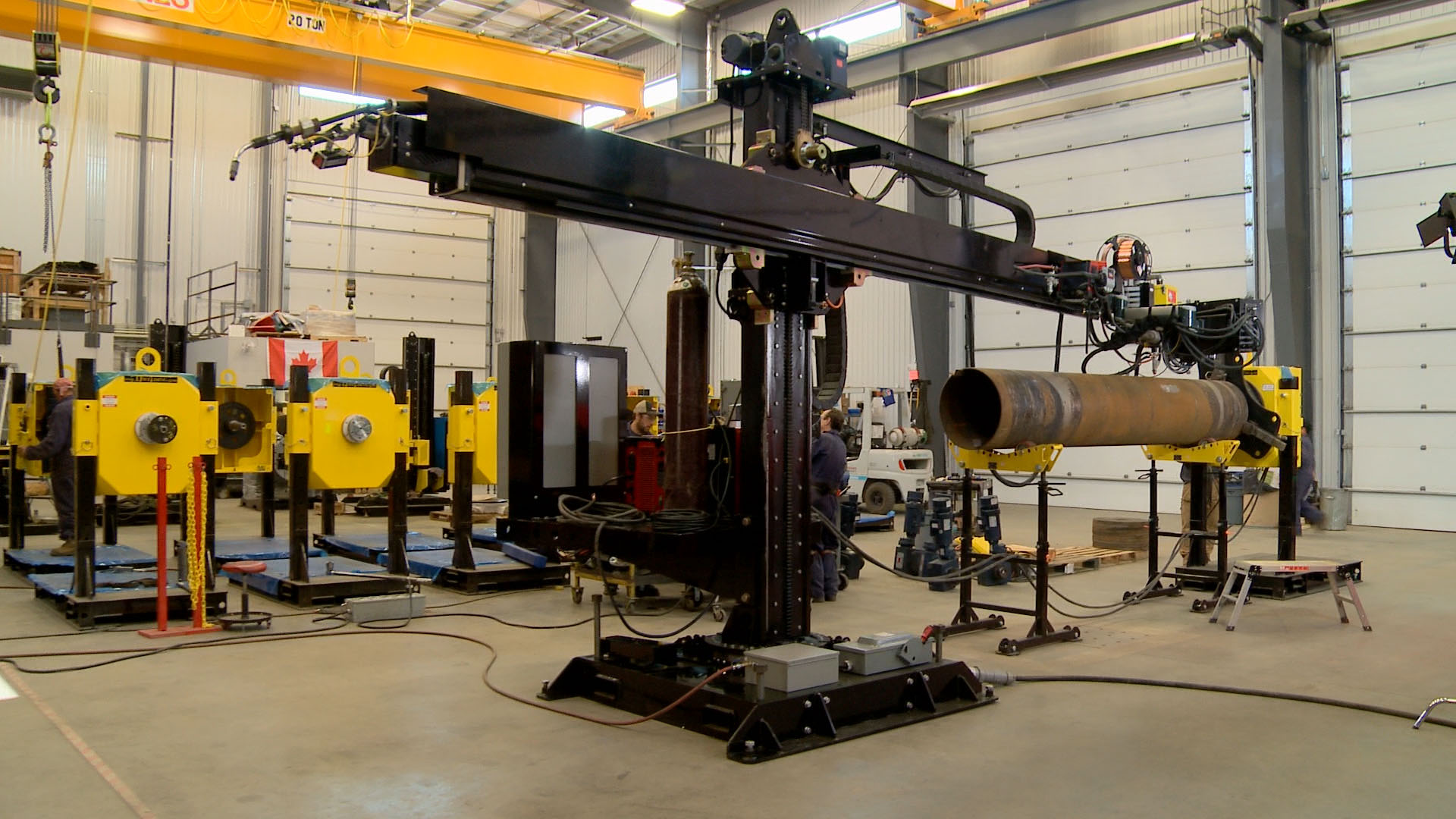

Column and Boom Welding Manipulator With Automated Dual-Head MIG + SAW Function

Situation

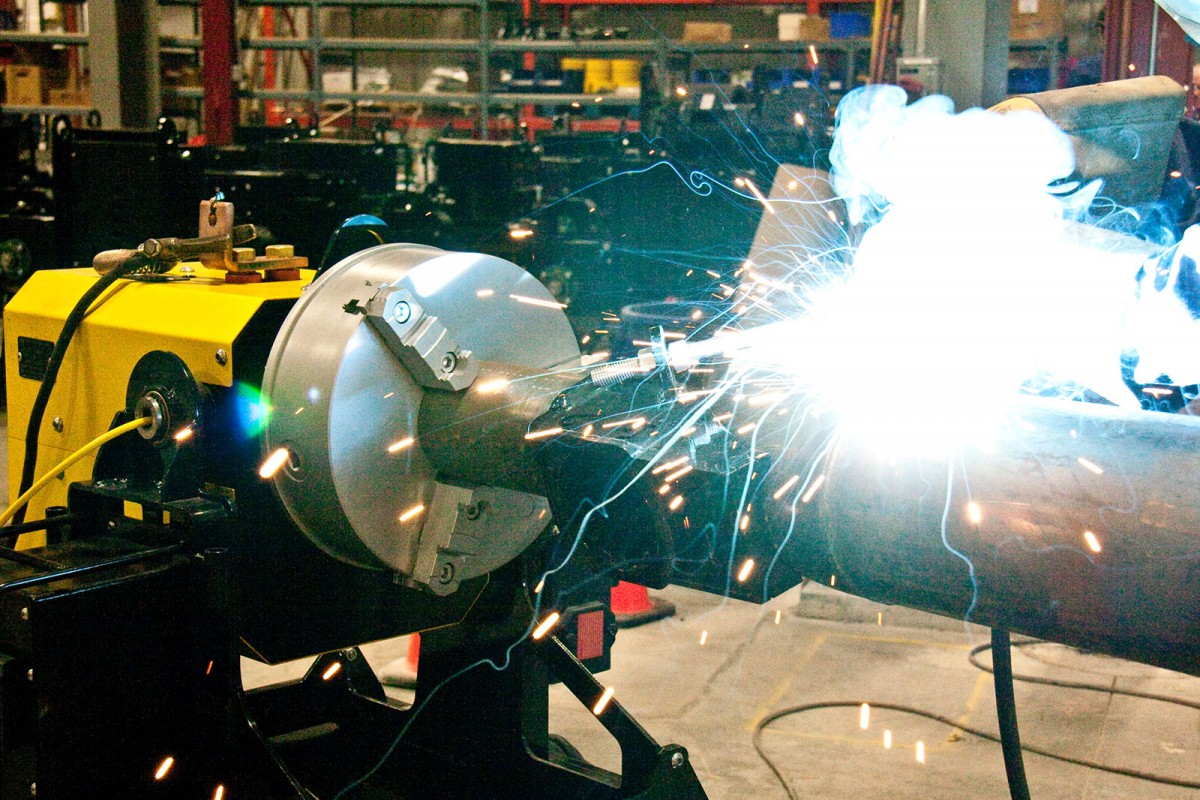

A pipe fabrication shop in Mexico was awarded a contract that required multi-process welding. First, they needed to stitch weld baffle plates, using a MIG process, along the inside long seam of an 18" diameter pipe up to 16 feet long...

Continue Reading