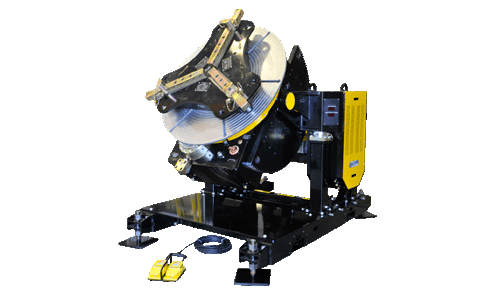

GEAR TILT & ROBOTIC WELDING POSITIONERS

- LJ’s Gear Tilt & Robotic Welding Positioners used for powered, variable speed tilting and rotation to automate and increase the welding productivity of cumbersome, heavy workpieces.

|

Worker’s Fatigue: Our Gear Tilt Positioners let the operator to be in one position when welding, preventing welder fatigue and allowing to weld in an ergonomic position |

|

|

Increased Productivity: Speedy operations and better efficiency of repetitive welding tasks in your shop |

|

|

Weld Quality: A wide range of loading capacities and rotation spans resulting in higher weld quality and precision |

|

|

Workshop Safety: Our Gear Tilt Positioners increase efficiency, safety and improve positioning of the workpieces when welding |

WHAT ARE WELDING GEAR TILT POSITIONERS?

Gear tilt positioners are versatile welding tools that provide the ideal angle for welding a variety of parts. These positioners are designed to tilt the workpieces around their horizontal axis, allowing welders to perform their work without having to constantly move and reposition their equipment. This feature increases efficiency and accuracy in welding operations, saving time and reducing costs.

Heavy-duty design and easy to use controls

These machines are equipped with high-quality gears and bearings that ensure smooth and precise movements during operation. Additionally, they have adjustable rotation and tilt speeds, making them adaptable to different welding requirements.

Our tilt turn gear driven welding positioners feature user-friendly controls that enable operators to adjust the tilting angles precisely. The controls also provide safety features that prevent the workpieces from tipping over during the welding process.

Interested in our Gear Tilt Positioners? Contact Us Today!

GEAR TILT WELDING POSITIONER SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT GEAR TILT POSITIONERS

How do positioners improve weld quality?

Positioners play an important role in improving weld quality, as they provide precise control over the position of components being welded and help keep them stable during welding operations. This allows for more accurate and consistent heat input, resulting in better joint penetration, fusion, and overall strength. Positioners also enable welding operators to access hard-to-reach areas that cannot be reached easily by manual means. Using a positioner ensures using the right amount of heat applied at the right angle on the joint surface. It also ensures that all critical parameters like travel speed and current setting are maintained accurately throughout welding operations.

Are the gear tilt positioners adjustable to different welding requirements?

Yes, our gear tilt positioners are adjustable to different welding requirements. They feature user-friendly controls that enable operators to adjust the tilting angles precisely and provide safety features that prevent the workpieces from tipping over during welding. Additionally, they have adjustable rotation and tilt speeds making them adaptive to different welding needs.

Are the products durable and reliable with minimal maintenance required?

Yes, the gear tilt positioners from LJ Welding are highly durable and reliable. Best of all, they require minimal maintenance which saves customers time and money in the long run.

Is there any support provided on how to operate them effectively?

Yes, LJ Welding provides full support to help customers learn how to operate their equipment effectively. This covers topics such as how to adjust the tilting angles and rotation and tilt speeds accurately according to specific welding needs. We go over the safety features in our control system as well so that customers know exactly how to prevent any tipping over incidents while using this equipment.

Side-By-Side Gear Tilt Welding Positioner Comparison

| Positioner Specifications | |||||

| Loading Capacity | 3,000 lbs (at 6" from chuck plate) | 6,000 lbs (at 12" overhung load) | 12,000 lbs (at 12" overhung load) | 24,000 lbs (at 12” overhung load) | 1,100 lbs (at 12” overhung load) |

| Footprint | 41-1/2” x 49-1/4” x 68-9/16” | 67-⅞” x 52-⅞” x 53” | 89” x 63-⅞” x 74-⅛” | 96-½” x 74-⅞” x 80” | 83⅞” x 48¼ x 53½” |

| Tilting Range | -45° - 90° (vertical mounting plate datum) | -45° - 90° | -45° - 90° | -45° - 90° | To be added |

| Tilting Torque | 45,000 in-lbs | 125,000 in-lbs | 250,000 in-lbs | 550,000 in-lbs | 35,000 in-lbs |

| Tilting Speed | 0.05 – 0.41 RPM (135° in 55 seconds) | 0.1 - 1.0 RPM (135° in 25 seconds) | 0.1 - 1.0 RPM (135° in 25 seconds) | 0.1 - 1.0 RPM (135° in 25 seconds) | 0.1–0.9 RPM (135° in 25 seconds) |

| Turning Torque | 15,000 in-lbs | 60,000 in-lbs | 125,000 in-lbs | 250,000 in-lbs | 20,000 in-lbs |

| Turning Speed | 0.225 – 2.8 RPM | 0.1 – 2.5 RPM (Other options available) | 0.05–2.2 RPM (Other speed options available) | 0.05 – 1.2 RPM (Other speed options available) | 0.1–2.2 RPM (Other speed options available) |

| Height Range | 33-1/2” – 57-1/2” | 32” - 52” (Adjustable in 4” increments) | 48-1/8” - 80-1/8” (Adjustable in 4” increments) | 50.5" - 82" | To be added |

| Mounting Plate Diameter | 22-1/8" (Various options available) | 42" (T-Slot Plate with 6 x 5/8" slots) | 48" (T-Slot Plate with 6 x 3/4" slots) | 60" (T-Slot Plate with 6 x 1" slots) | To be added |

| Power Requirements | 240V, 1-ph, 9A, 60Hz | 480V, 7A, 3-ph, 60Hz | 480V, 13A, 3-ph, 60Hz | 480V, 21A, 3-ph, 60Hz | 208 V, 3-ph |

| Ground Capacity | 800 Amps | 800 Amps | 1,500 Amps | 1,500 Amps | 800 Amps |

| Weight | 1,851 lbs | 3,702 lbs | 7,745 lbs | 11,094 lbs | 2,750 lbs |

* Excluding gripper. Specifications subject to change; consult factory for all specifications.

-1.png?width=100&height=100&name=T3PS3%20positioner%20(1)-1.png)