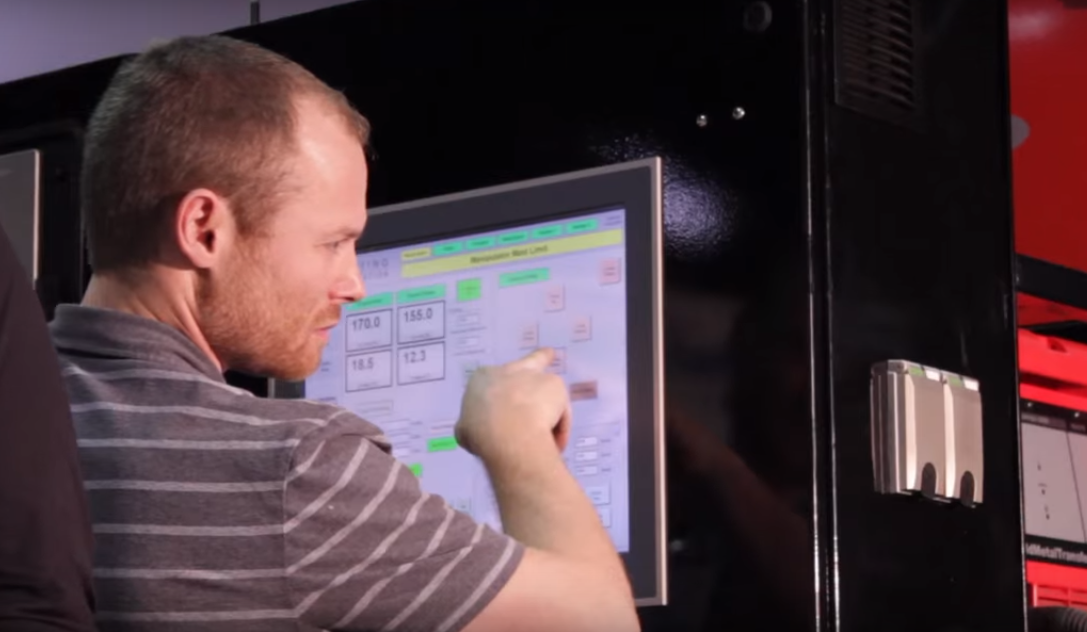

What Are HMI Touch Screen Controls?

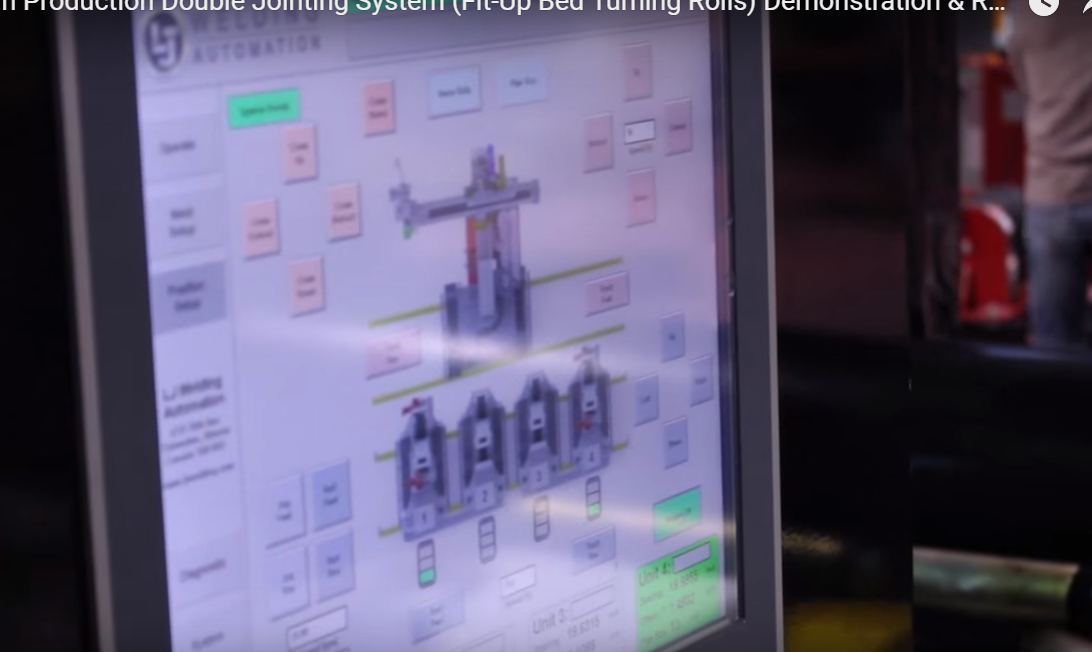

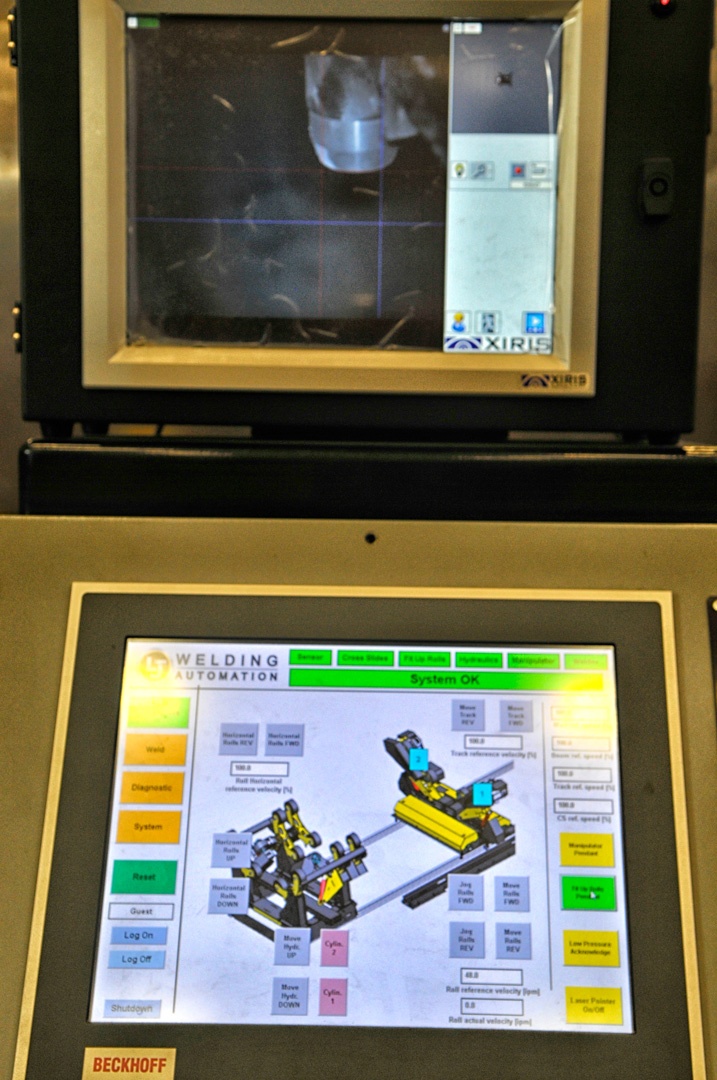

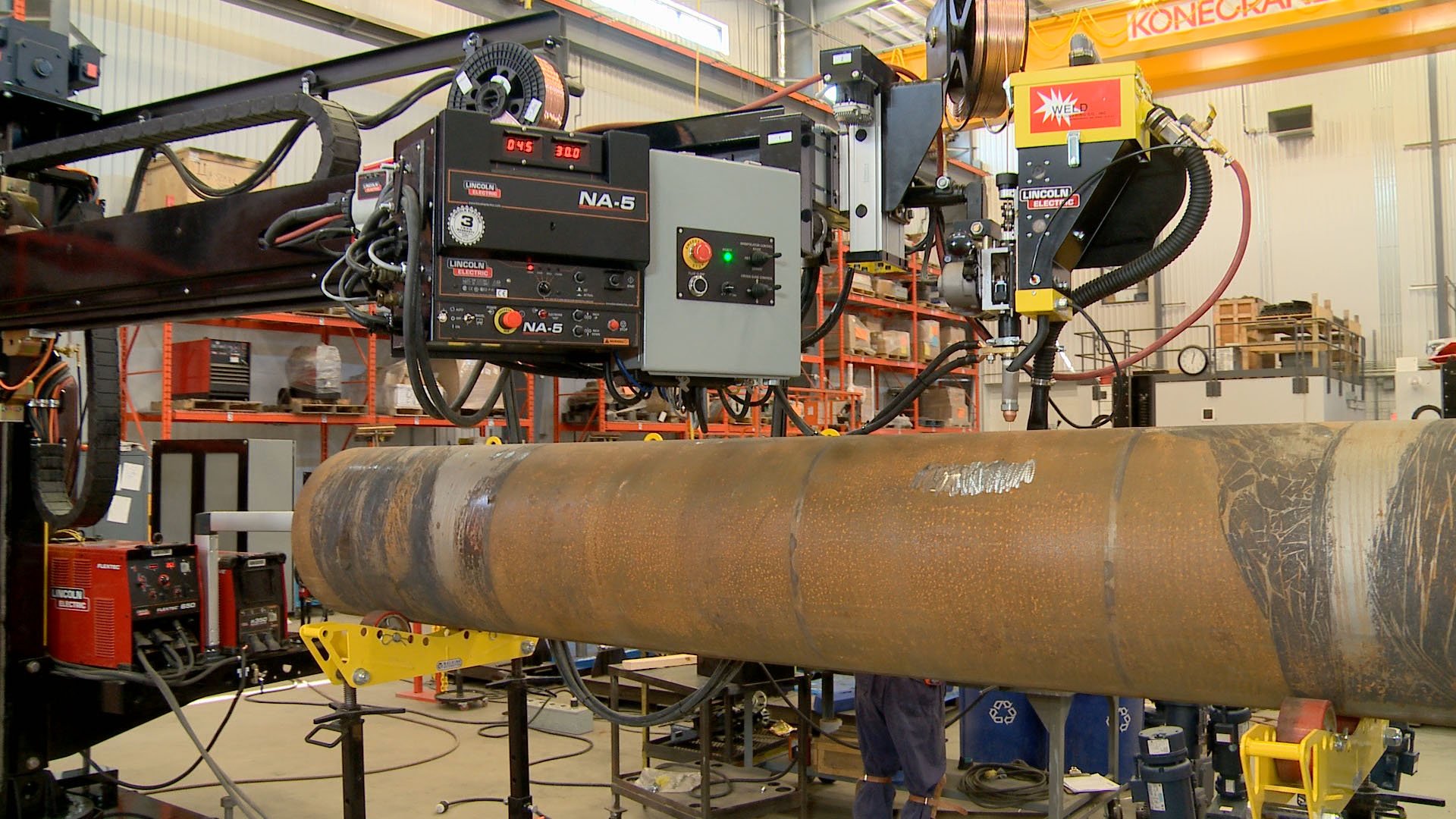

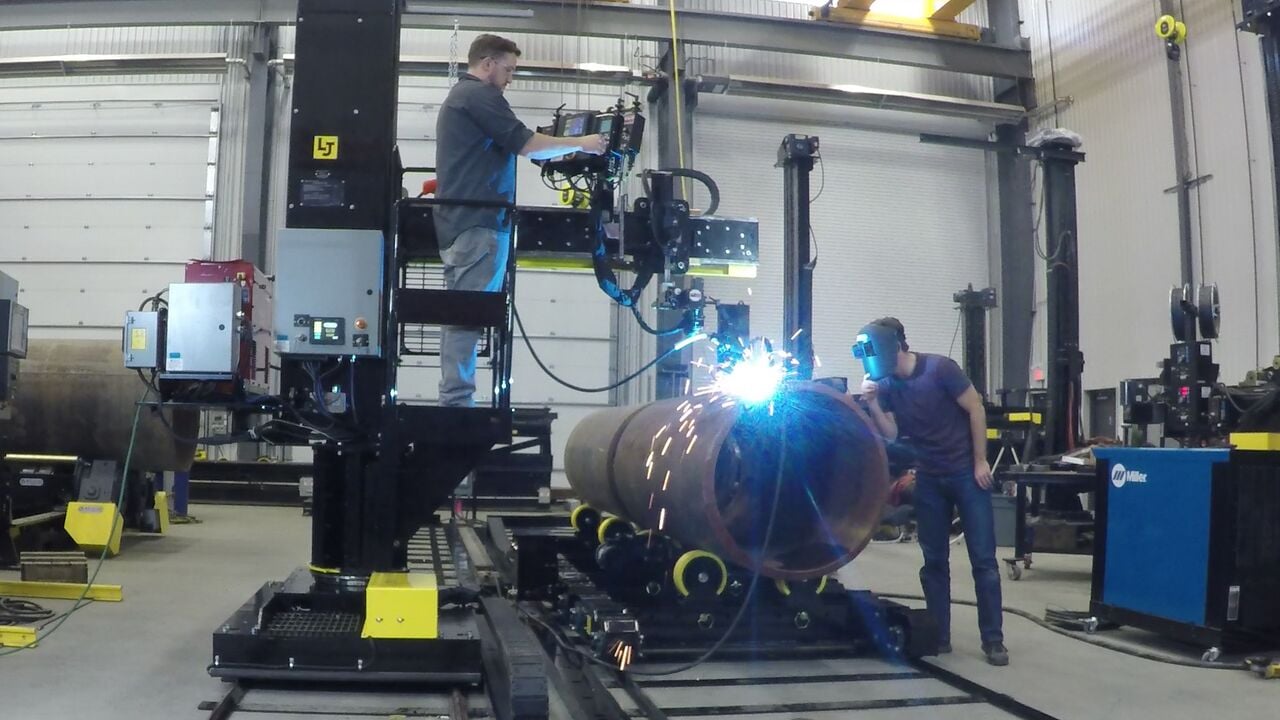

HMI (Human machine interface) is the computer interface that communicates and commands all major functions of your welding manipulator or beam welding gantry system.

What Can the HMI Touch Screen Control?

- Rotation speed of rollers and positoners.

- Weld speed.

- Height adjustment (positioners if powered height adjust.)

- Welding controls.

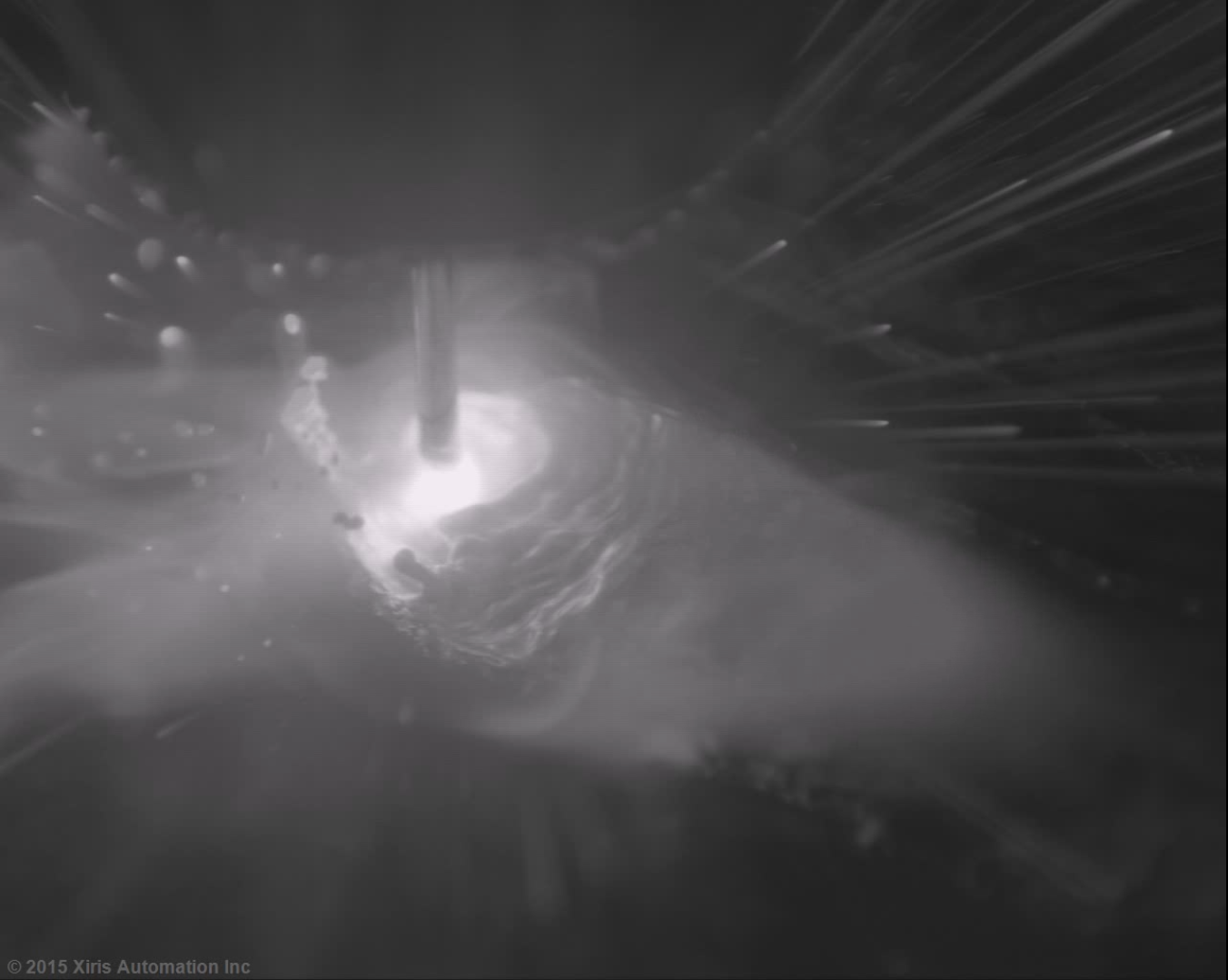

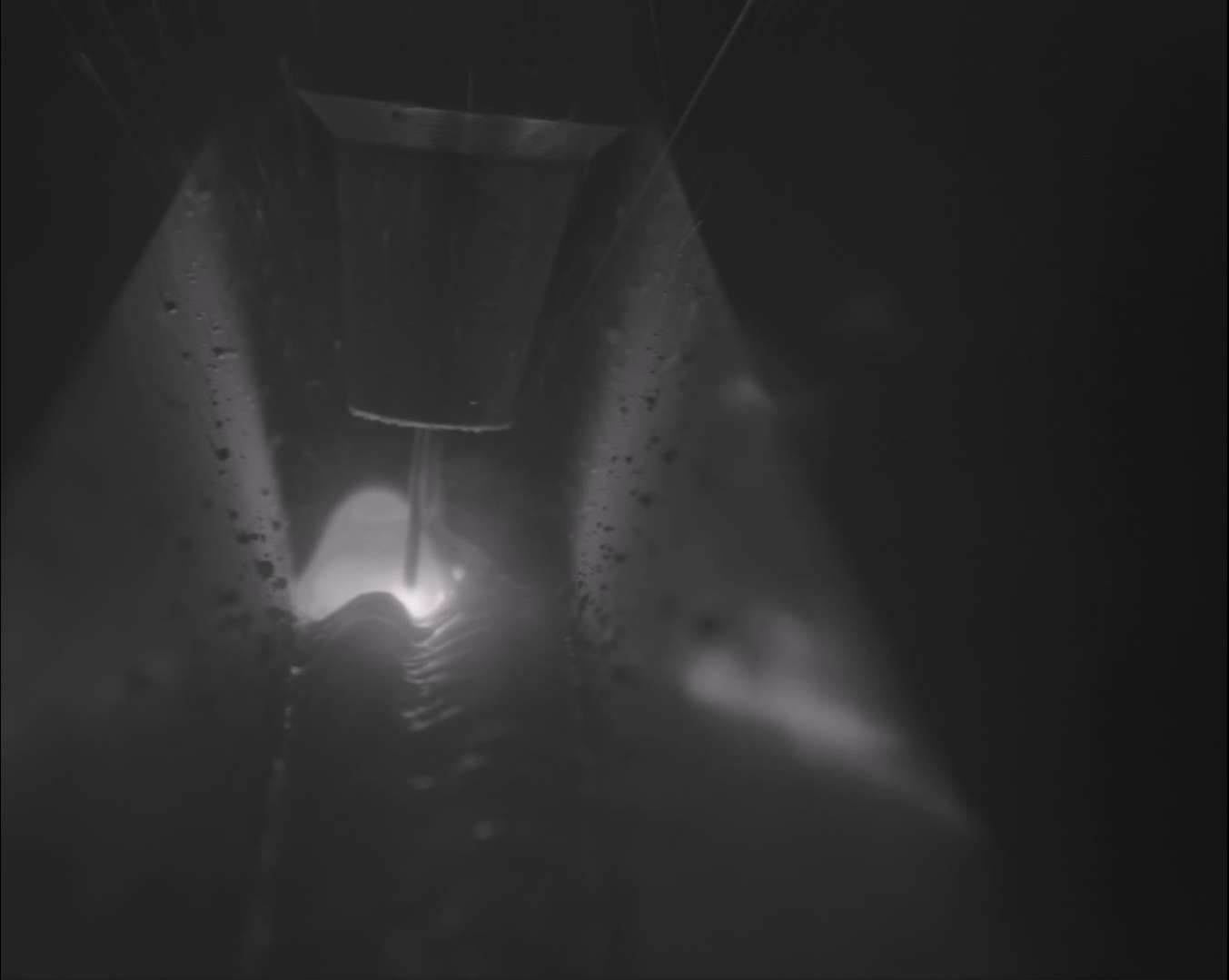

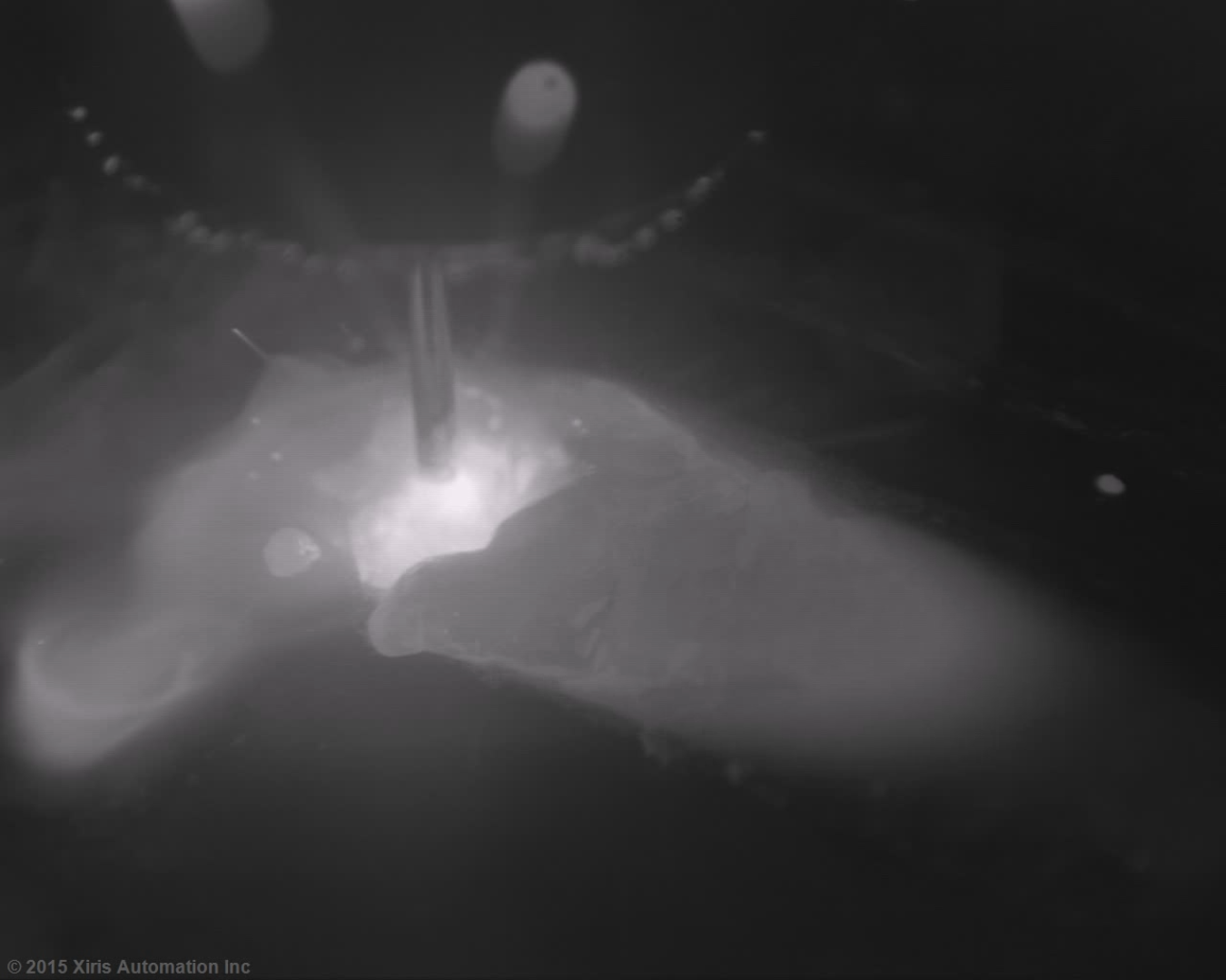

- Camera.

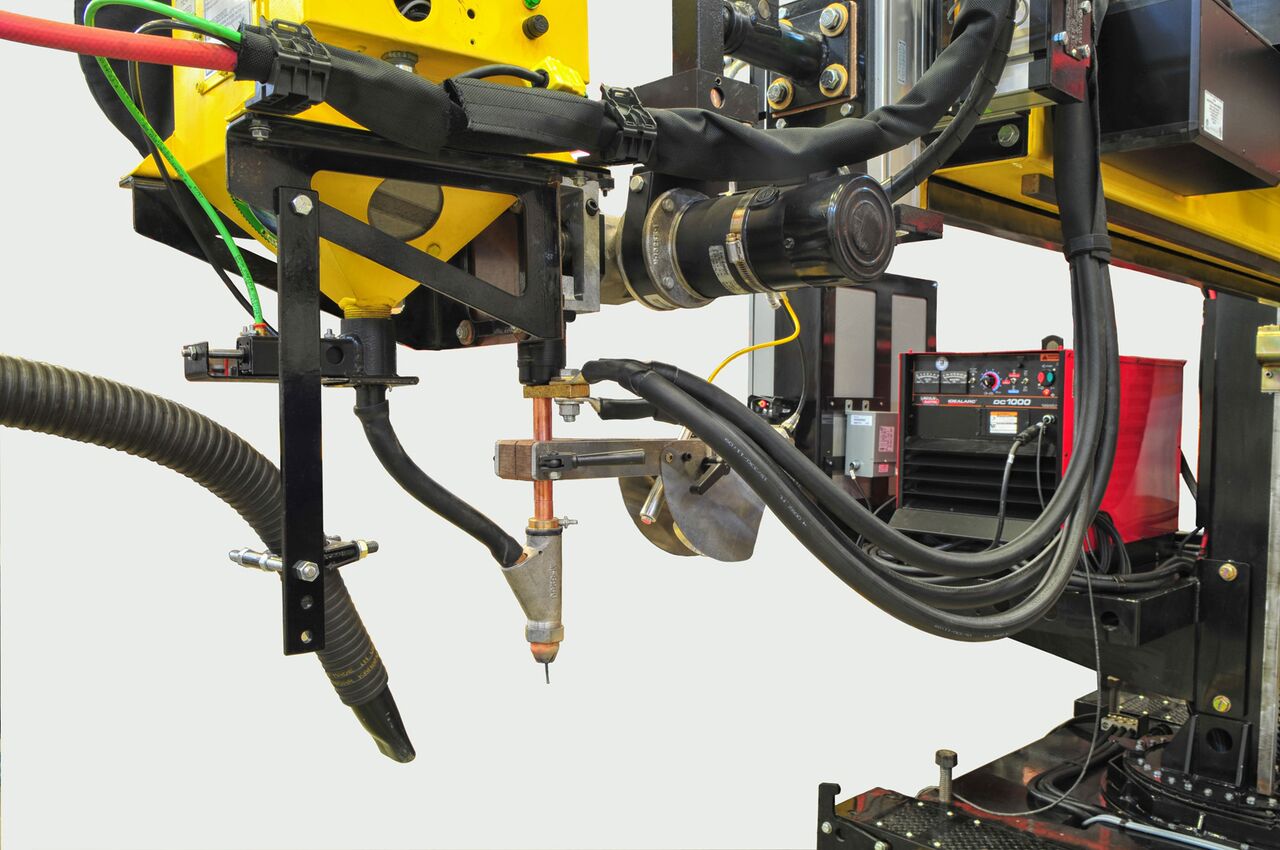

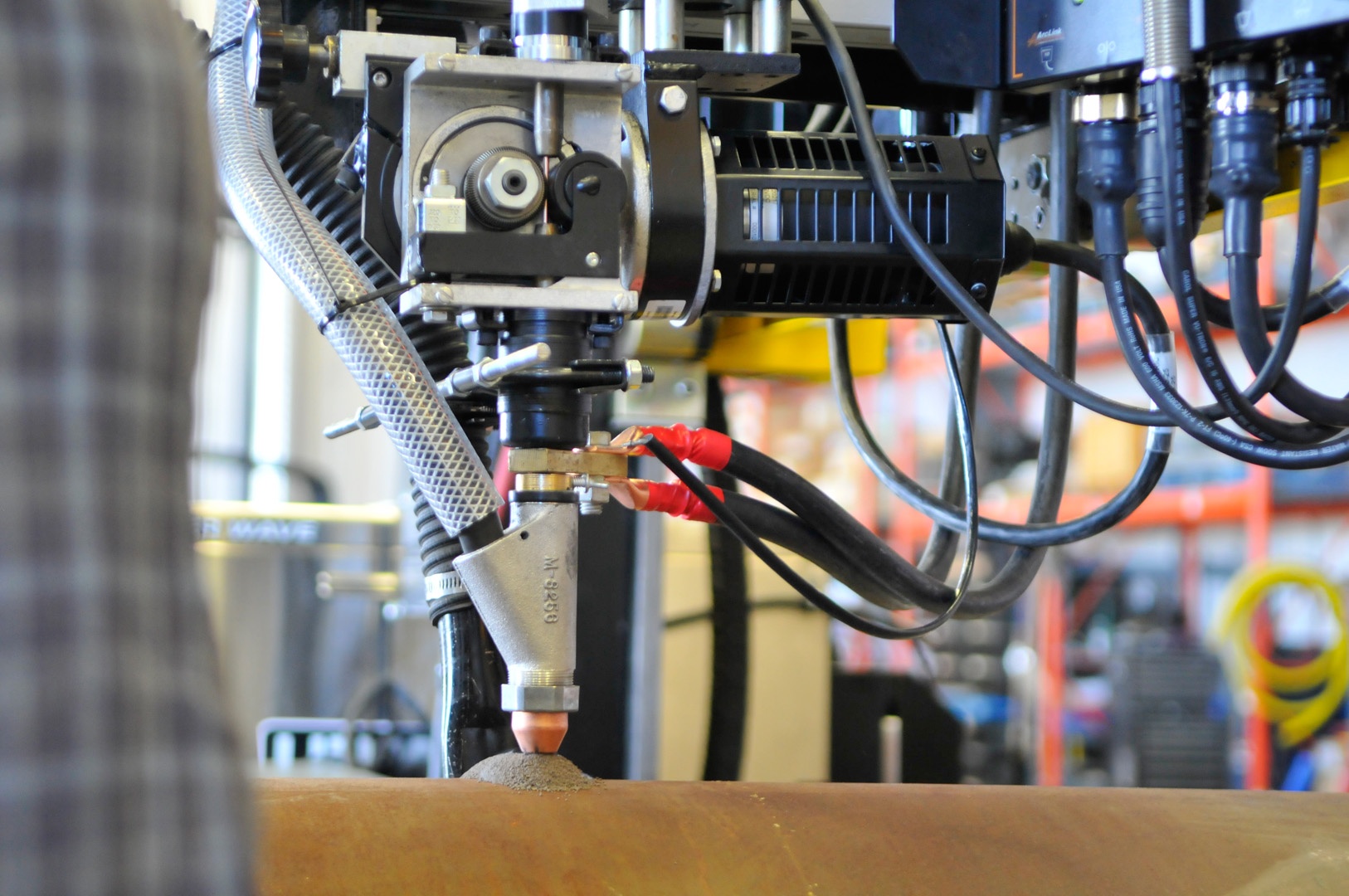

- Seam tracking.

- Data Collection

How Do I know If I Should Choose HMI Controls For My Welding Application?

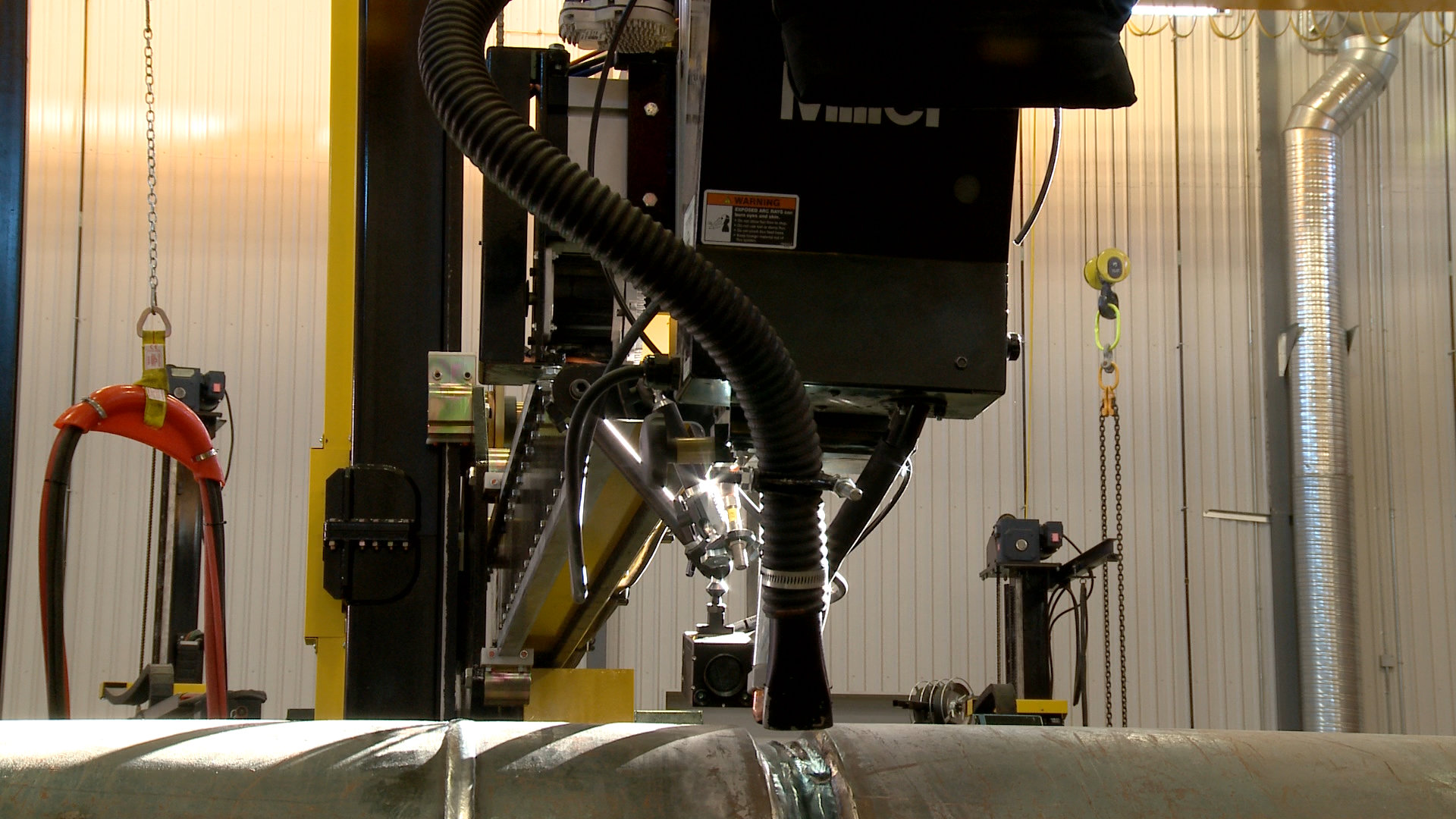

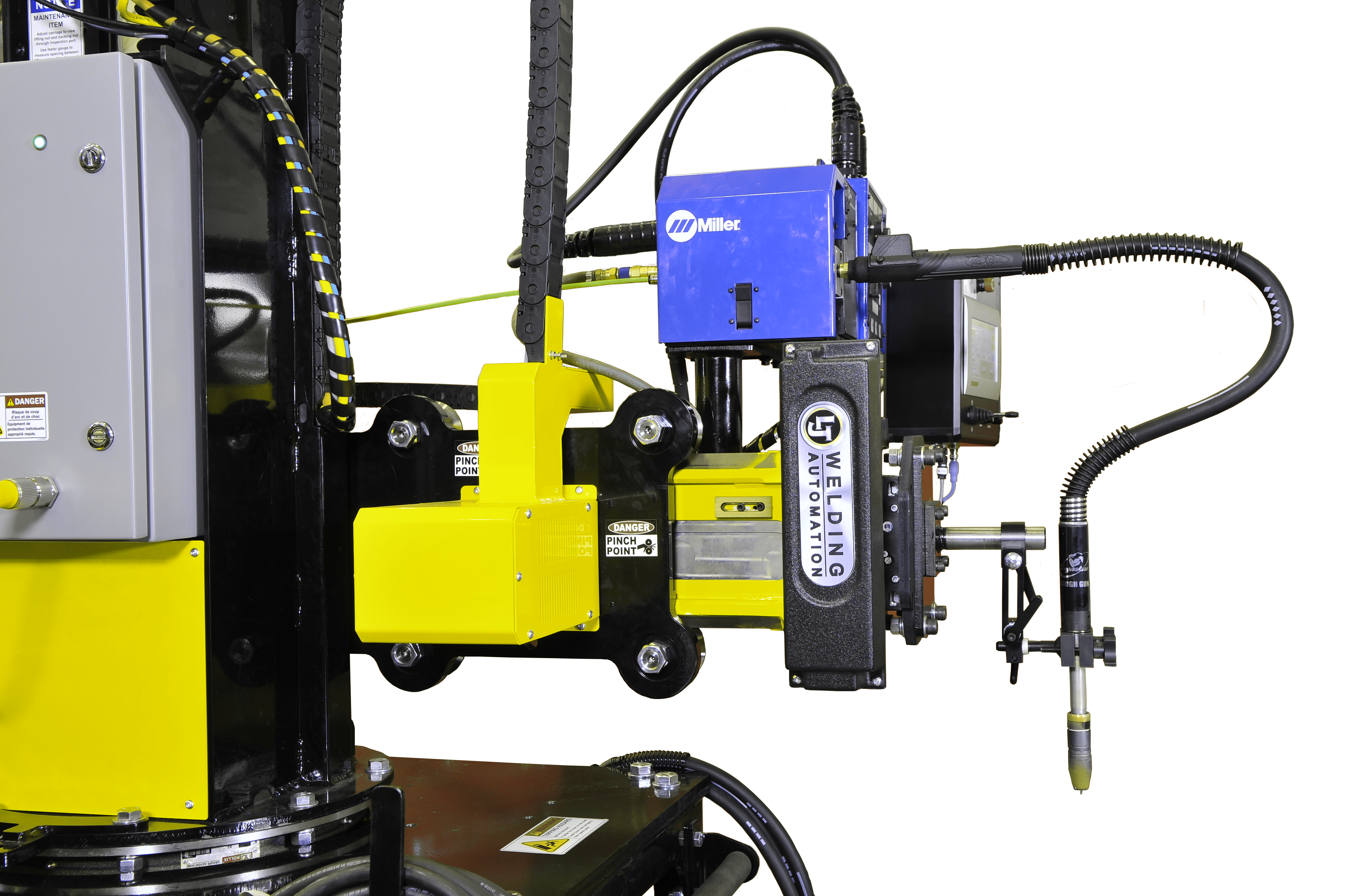

It will depend on the complexity of your welding application, scope and budget. If your application has many moving parts, such as seam tracking, welding turning rolls, a column and boom manipulator and camera, an HMI would streamline all variable factors into a simplified screen.

If you aren't integrating your CaB manipulator with any other material handling equipment, standard equipment controls are sufficient.

HMI Controls Further Reading

The HMI control is a PC based computer that is easy to set or change, store useful data for quality assurance purposes, and can fully integrate with all LJ Welding products. The HMI touchscreen panel controls all complex welding automation functions from one single location.