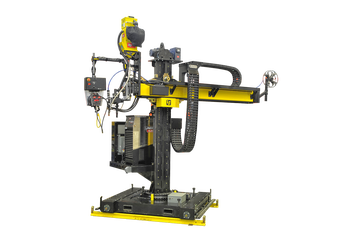

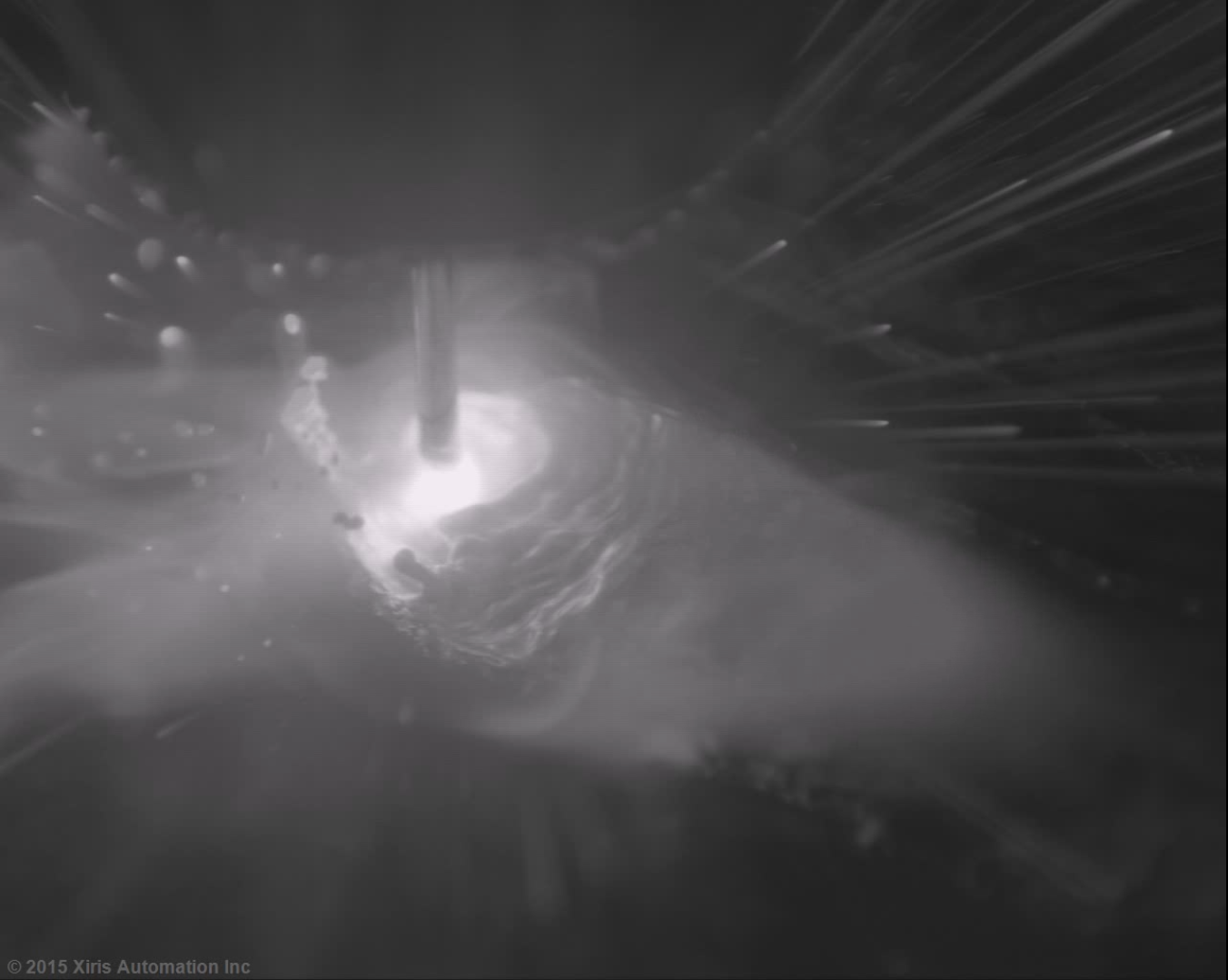

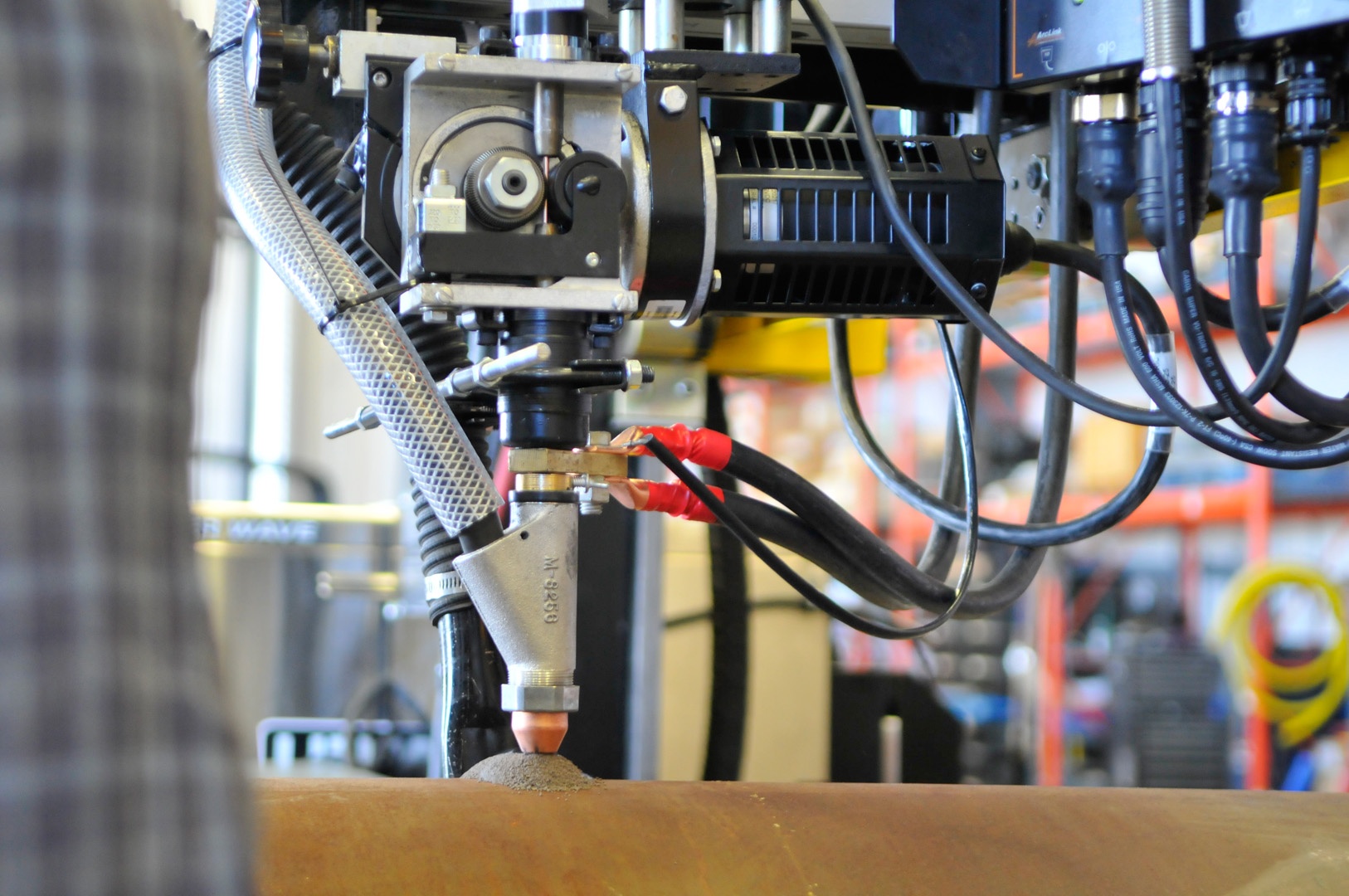

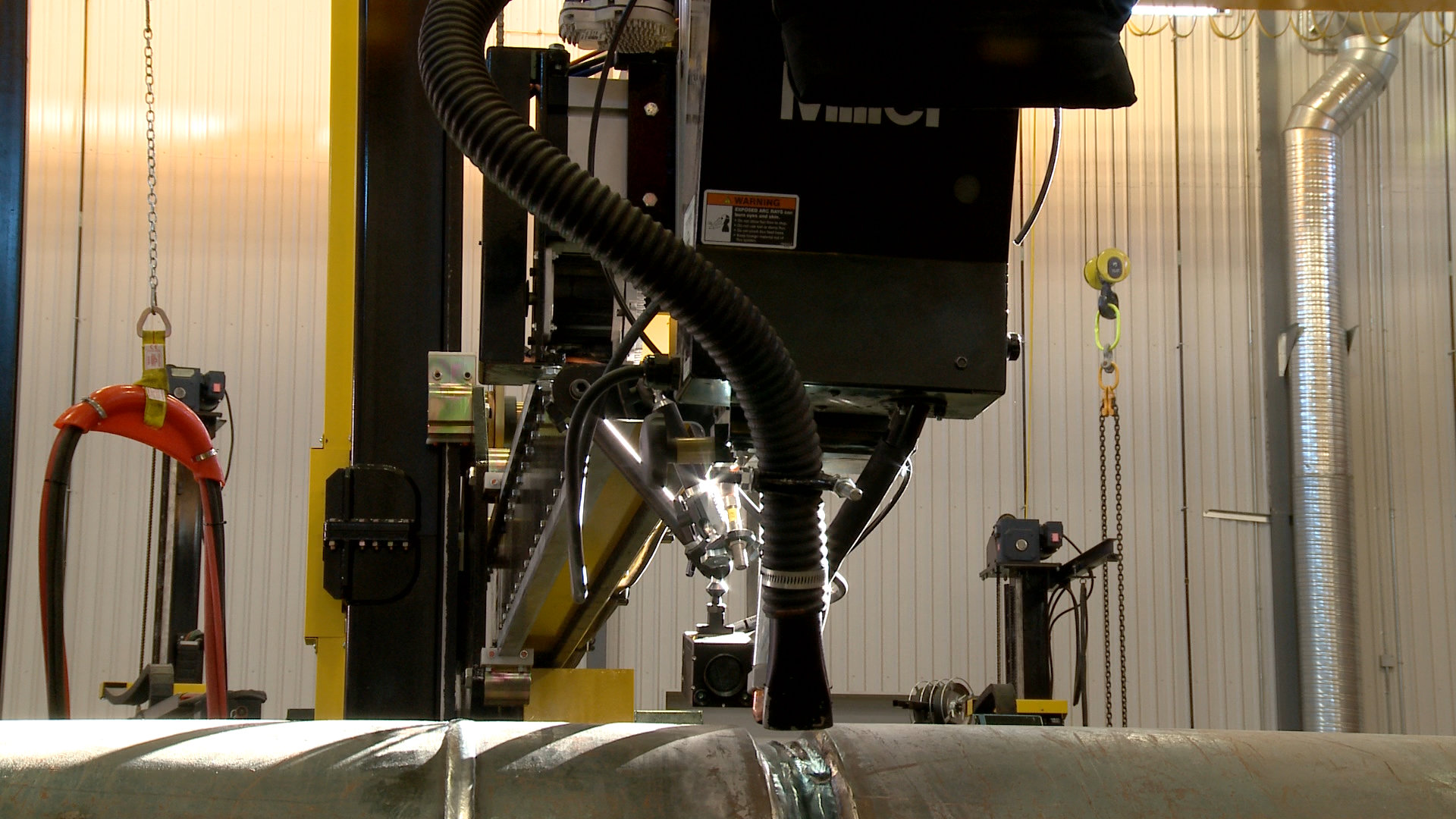

Column and Boom (C&B) welding manipulators most commonly use Submerged Arc Welding (“SubArc” or SAW) equipment because SAW is widely known to be the most economical and highest quality welding process for many applications. It is known for high deposition rates, high travel speeds, no spatter, low fume, no exposed arc, and consistent weld quality through a wide range of weld parameters.

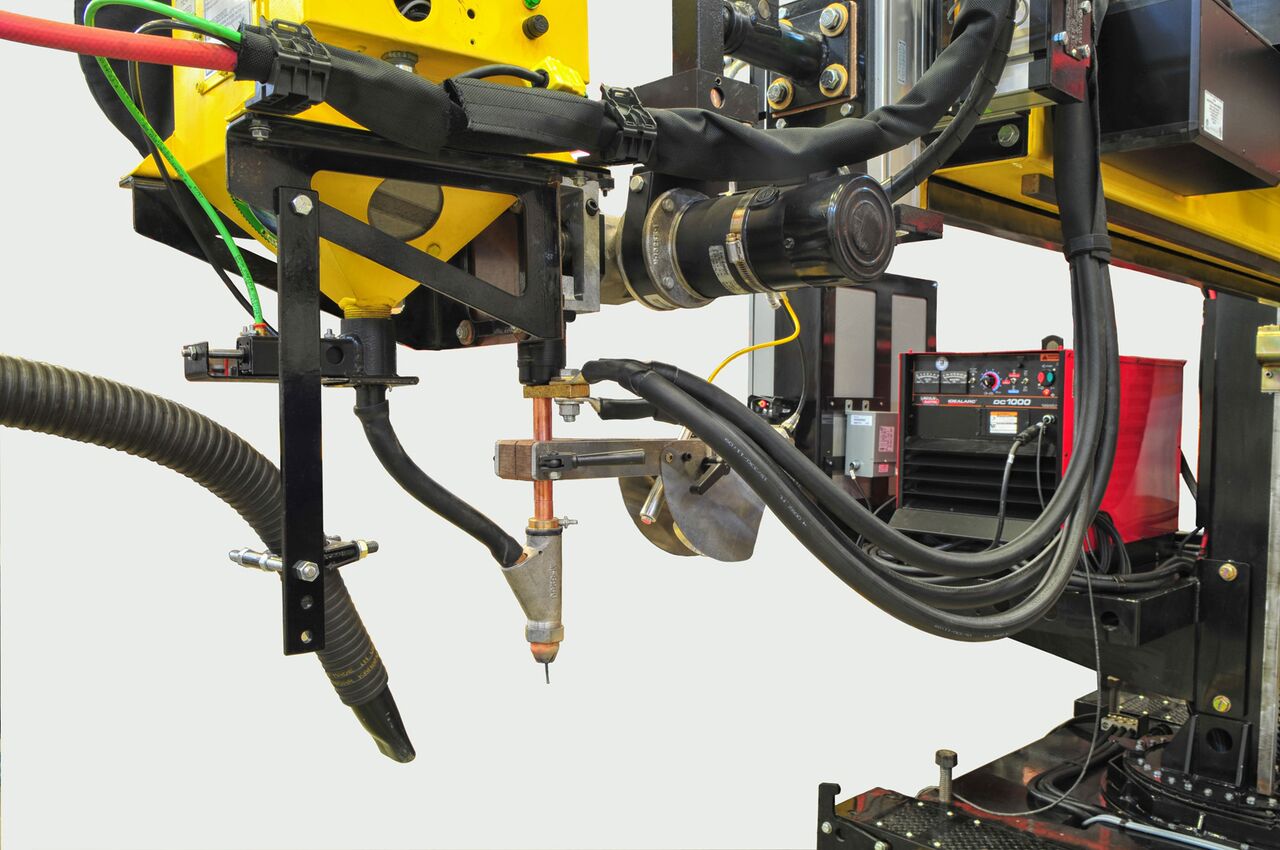

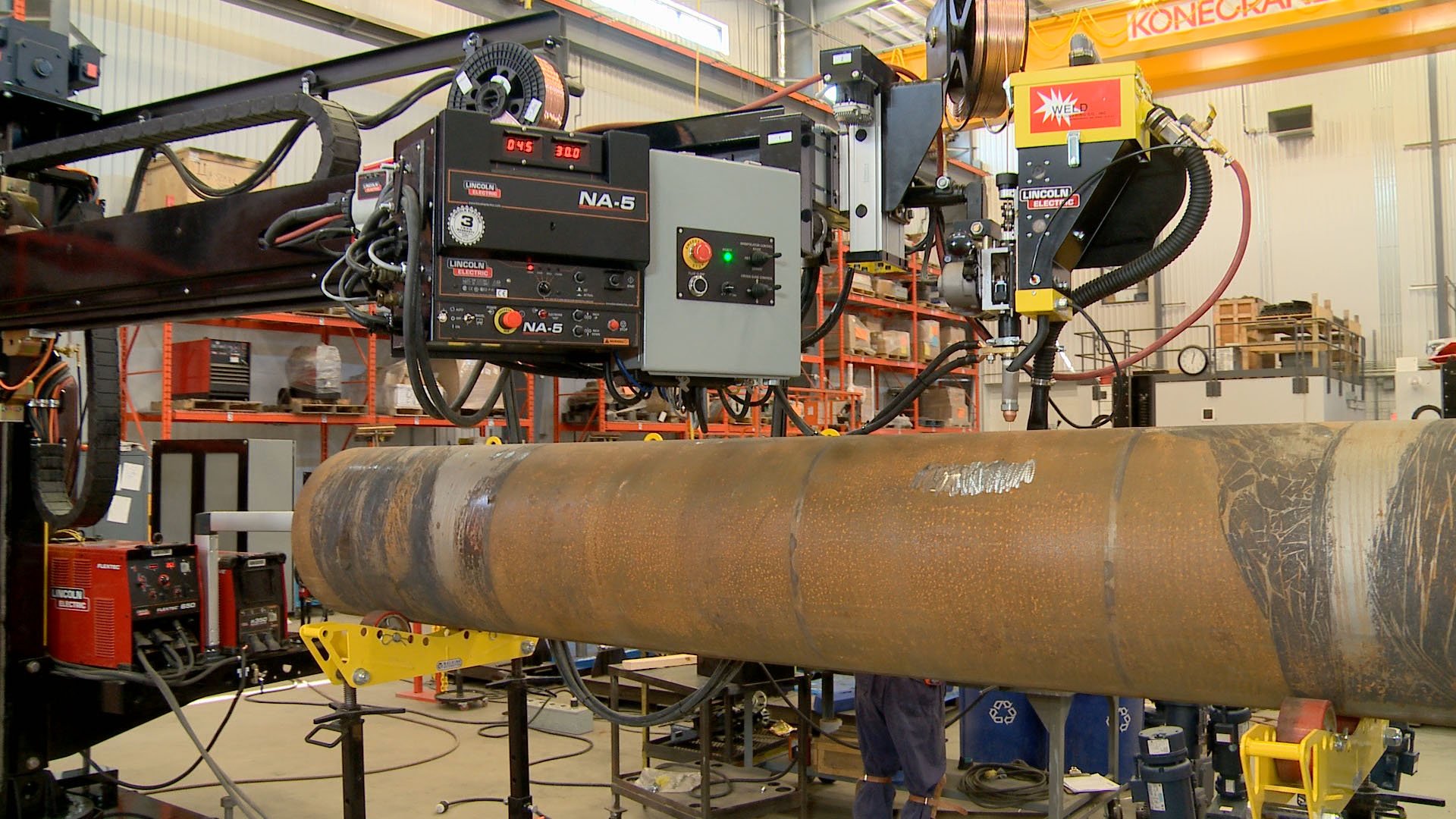

Conventional SAW is generally done using DC current and electrode positive polarity. DC SAW power sources are available in a range of outputs. LJ recommends the following power source and controller configurations, with other configurations available upon request: Miller SubArc DC Digital 650, 800, 1000 or 1250 with SubArc Motor Control Digital and PLC control from the HMI using ModBus; Lincoln FlexTec® 650X with MAXsa 10 Controller. Other available DC SAW power sources are the Lincoln Idealarc® 1000 and 1500, which are paired with the NA-5 Controller.

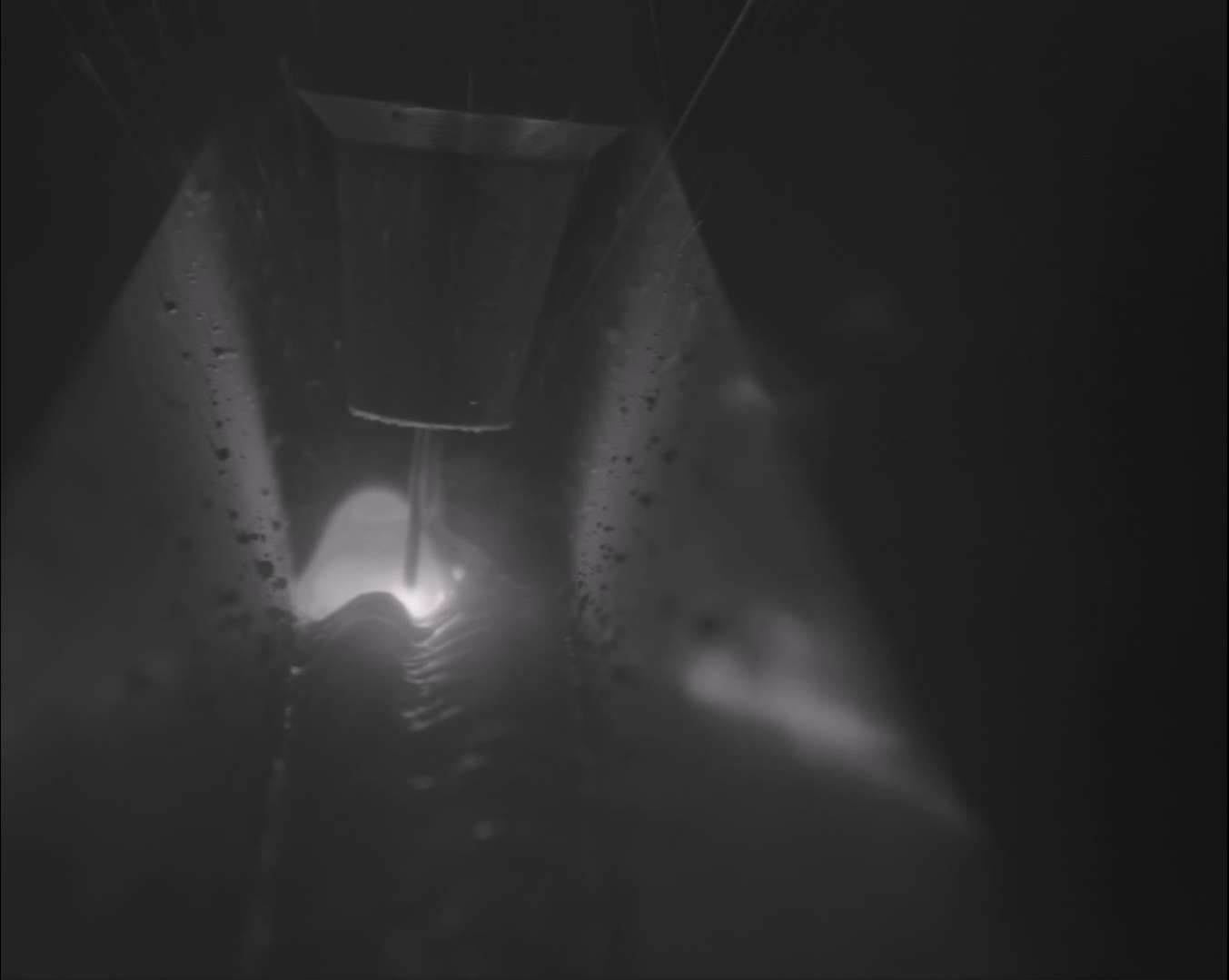

The following square wave SAW power sources are all capable of DC welding, as well as variable-balance AC. The main benefits of square wave AC SAW over DC SAW are shallower and broadened penetration profile (lower burnthrough risk and larger process window, especially on thinner materials), increased deposition rate for a given heat input (which can allow increased welding travel speeds and/or reduced arc time), lowered base material dilution, and reduced tendency for arc blow/wander. The use of square wave SAW power sources also allows the potential for tandem and triple arc configurations for dramatic productivity enhancement. LJ recommends the following power source and controller configurations, with other configurations available upon request: Lincoln Power Wave® AC/DC 1000® SD with Lincoln MAXsa® 19 Controller with LJ PLC control of parameters, Lincoln Power Wave® AC/DC 1000® SD with Lincoln MAXsa® 10 Controller; Miller SubArc AC/DC Digital 1000 or 1250 with Miller SubArc Motor Control Digital with LJ PLC control of parameters, Miller SubArc AC/DC Digital 1000 or 1250 with Miller SubArc Motor Control Digital and Miller SubArc Remote Pendant Digital.