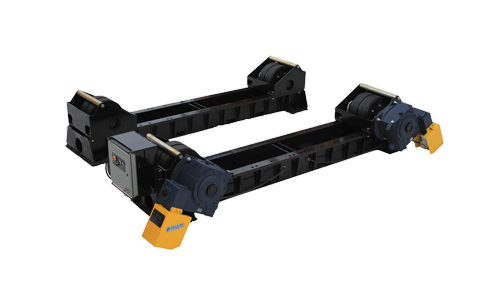

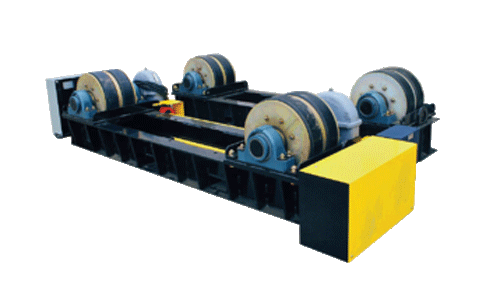

TURNING ROLLS: FIXED HEIGHT VESSEL ROLLERS

- LJ's fixed height vessel rollers have the largest diameter range and best in its class specifications. Driveshaft-free dual drives with synchronized rotation provide maximum traction and control.

|

Synchronized Rotation: Our Fixed Height Vessel Rotators maximize the ease & quality of welds using synchronized rotation and reduce pipe preparation costs |

|

|

Increased Effectiveness: Reducing idle time using cranes and manual manipulation while increasing throughput and safety of workers |

|

|

Smooth Integration: Seamless integration with manipulator applications that maximize vessel fabrication productivity |

|

|

Quick Change-Overs: Maximizing ease & quality of welds using synchronized rotation providing maximum traction and control |

|

|

Heavy-Duty Design: Our Fixed Height Vessel Rotators are designed to help your production process and they can be easily adjusted to your fabricating requirements |

WHAT ARE FIXED HEIGHT VESSEL ROLLERS?

Our fixed height vessel rollers are a reliable and accurate rotating solution for fabricators in the manufacturing space. Besides precise ergonomics and durability, these fixed height turning rollers help our customer to increase productivity as well as safety in their welding shops.

In terms of the design features, our fixed height vessel rollers are designed to cater to a variety of applications, to meet our customer’s needs. Composed of an idler and driver, the fixed height turning rolls are an excellent tool for rotation and rolling of heavy-duty pipes, boilers, tanks, and other cylindrical objects.

Reduced crane use & pipe preperation costs

Fixed height vessel rollers provide various advantages to the overall performance of production. Dual drives with synchronized rotation allow for maximum control and traction without a driveshaft, while quick changeovers between different sized workpieces are enabled.

Furthermore, seamless integration with manipulator systems is possible due to the automatic alignment of the rollers without requiring manual manipulation. These features reduce pipe preparation costs, crane use, and idle times in work stations; moreover, welding efficiency and safety can also be improved.

With the largest diameter range in its class, along with drive shaft-free dual drives that provide maximum traction and control, the fixed height vessel rollers can help you save time on pipe weld prep while also reducing idle times and increasing productivity.

Interested in our Fixed Height Vessel Rollers? Contact Us Today!

LJ'S FIXED HEIGHT VESSEL ROLLERS SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT FIXED HEIGHT VESSEL ROLLERS

What are the benefits of using fixed height vessel rollers?

The main benefit of using fixed height vessel rollers is that they provide a more stable platform for cylinder or spherical vessels during welding. Fixed height vessel rollers are also much easier to set up, since they do not need to be adjusted according to the specific project's requirements. They are often used in basic welding tasks that don't require any customization or special adjustments, as well as projects with tight deadlines where time saved is important. Because they do not require multiple pieces of equipment or complex setup procedures, fixed height vessel rollers can be cost effective when compared with other types of welding turning rolls on the market.

What type of welding tasks can be completed with fixed height vessel rollers?

As mentioned before, fixed height vessel rollers can be used to weld a variety of cylindrical and spherical vessels, such as tanks, pipes and other shapes. They can be used in welding operations where exact positioning is not necessary or when time is of the essence. With a few simple adjustments, fixed height vessel rollers can provide you with an efficient and reliable welding solution for many types of projects.

Is it possible to adjust the height of fixed vessel rollers?

While it is possible to adjust the height of some models, generally they should be used at their designated height only and any adjustments should always be double checked before use. Making incorrect adjustments could cause instability during the welding process and lead to poor-quality welds or other potential hazards. It is highly recommended that you consult with an experienced professional if attempting to make any changes to these tools.

How do I set up and use fixed height vessel rollers?

Setting up and using fixed height vessel rollers is a straightforward process that requires minimal preparation. It is important to always read the instructions carefully before use to ensure proper setup. Make sure they are secured firmly on the floor or mobile base, check for any weight restrictions on the product, double check all adjustments, then you are ready to begin welding. Be sure to wear appropriate safety gear and have an experienced partner as backup in case of emergency.

Side-By-Side Fixed Height Vessel Rotators Comparison

| Specifications | ||||

| Loading Capacity |

Driver: 60,000 lbs (30-ton); Idler: 60,000 lbs (30-ton) |

Driver: 80,000 lbs (40-ton); Idler: 80,000 lbs (40-ton) |

Driver: 120,000 lbs (60-ton); Idler: 120,000 lbs (60-ton) |

Driver: 200,000 lbs (100-ton); Idler: 200,000 lbs (100-ton) |

| Footprint | Driver: 60-1/4" x 146-9/16" x 46"; Idler: 60-1/4" x 128" x 46" |

Driver: 51-5/8" x 195-3/8" x 38"; Idler: 36" x 162" x 33-1/2" |

Driver: 49-1/2" x 190-1/4" x 38"; Idler: 36" x 162" x 31-1/2" |

55-3/4" x 188-1/8" x 34-5/8"; Idler: x 42" x 162-1/4" x 31-1/2" |

| Diameter Range | 12” - 216” | 18” - 312” | 18” - 312” | 18” - 312” |

| Tractive Effort | 8,800 lbs (Dual drive) | 12,000 lbs (Dual drive) | 20,400 lbs (Dual drive) | 20,400 lbs (Dual drive) |

| Turning Torque | 120,000 in-lbs (Dual drive) | 120,000 in-lbs (Dual drive) | 240,000 in-lbs (Dual drive) | 240,000 in-lbs (Dual drive) |

| Turning Speed | 5-70 in/min | 5 – 50 in/min | 5 – 70 in/min | 5 – 70 in/min |

| Height Range | 44-5/8" - 65-5/8" (top of wheel), Adjustable in 3" increments | 31-½” (Top of wheel), Fixed height | 31-½” (Top of wheel), Fixed height | 31-1/2” (Top of wheel), Fixed height |

| Power Requirements | 208V, 3-ph (optional: 480V, 3-ph or 600V, 3-ph) | 480 V, 3-ph | 480 V, 3-ph | 480 V, 3-ph |

| Weight |

Driver: 5,020 lbs; Idler: 4,159 lbs |

Driver: 6,863 lbs; Idler: 5,760 lbs |

Driver: 6,955 lbs; Idler: 5,075 lbs |

Driver: 9,500 lbs; Idler 7,535 lbs |

-1.png?width=100&height=100&name=80T-700-800-thumb-300%20(1)-1.png)

.png?width=100&height=100&name=120T-500-600-thumb-300%20(1).png)