PIPE TITAN | SMALL BORE PIPE WELDING

KEY SPECIFICATIONS

|

Pipe Size Diameter |

2" to 24" |

|

Pipe Weld Prep Requirements |

As purchased or torch cut, power-brushed to remove oxide |

|

Root Pass Requirements |

Mechanized using EWM rootArc & rootArc Puls

(ability for greater fit-up tolerances) |

|

Fill & Cap Passes |

EWM GMAW Standard/Pulse or forceArc |

|

Productivity Per Set-Up |

With a 2nd power supply, the 2nd positioner can be used for setup and root welding (double productivity with less floor space) |

|

Narrow Groove Joint Capability |

30° include angle with forceArc after root pass, reducing the number of weld passes by 50% |

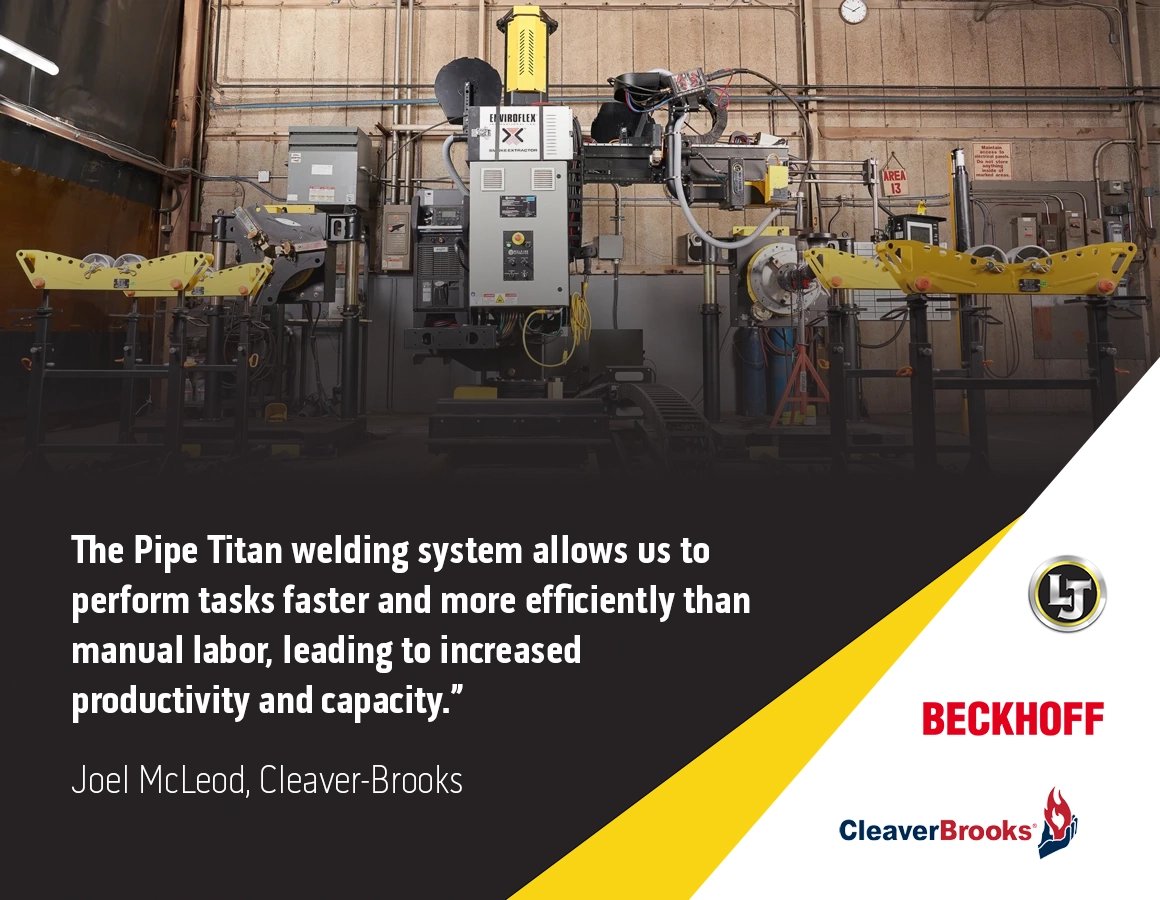

CUSTOMER TESTIMONIAL

Tripling Production Efficiency with LJ's Pipe Titan Welding System

Cleaver-Brooks, a global provider of efficient boiler room solutions, with a focus on reducing energy usage, cost and environmental impact, approached LJ Welding with the requirements to reduce costs, and improve quality in their operations.

By leveraging PC-based automation from Beckhoff, LJ Welding implemented a system that surpassed Cleaver-Brooks' requirements.

Cleaver-Brooks reduced arc time by 63%, which is nearly three times faster.

The system also led to a 90% reduction in weld clean-up time, a 10% reduction in rework, and a 39% reduction in filler metal spend.

Key Benefits

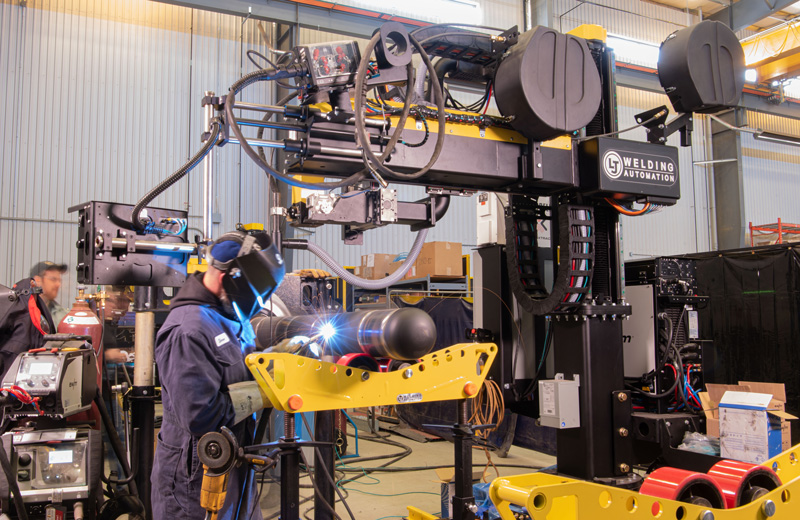

Improved Productivity

The Pipe Titan system enables two welders to work on two separate joints simultaneously using a single system. This unique feature effectively doubles the output with minimal floor space requirement, ensuring maximum efficiency on the work floor.

Faster Travel Speeds

The system provides a semi-automatic root pass allowing for faster travel speeds during the welding process. This not only reduces completion times but also ensures a consistently high-quality weld across various thicknesses and material types.

Reduced Machining Requirements

Its tolerance for sound weld deposits eliminates the need for machining most pipe IDs. This results in significant time and cost savings for users, as well as a reduced need for specialized equipment and labor.

Long-Lasting Durability

Constructed with heavy-duty mechanical components, the Pipe Titan system ensures long-term durability and reliability. This investment in quality materials and construction translates to less downtime and lower maintenance costs for users.

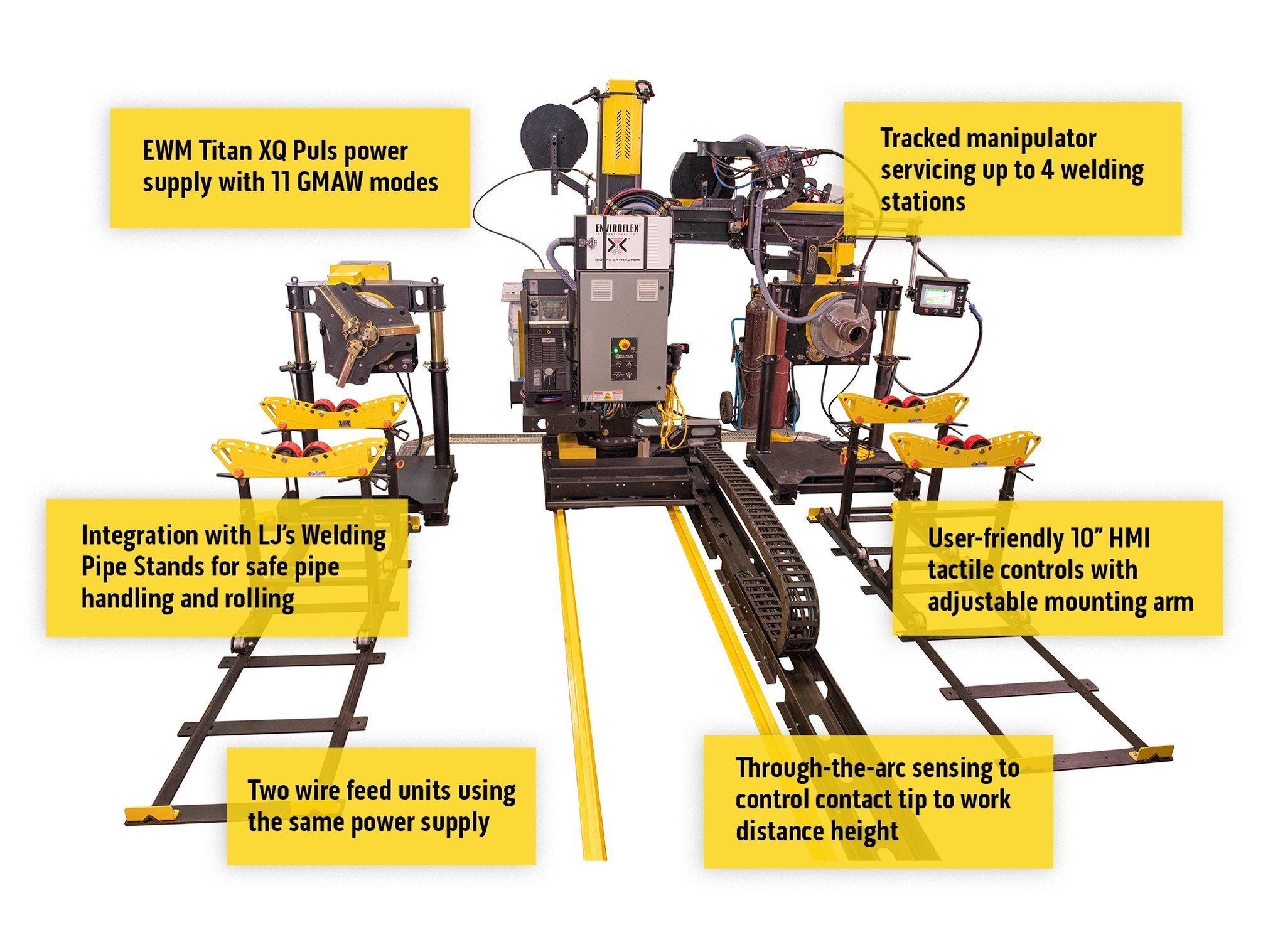

User-Friendly Controls

The Pipe Titan system features a 10-inch HMI tactile control panel with an adjustable mounting arm, making operation easy and efficient, thus allowing operators to quickly access and adjust settings.

Optimized Welding Results

The system comes with the EWM Titan XQR 500 Power Supply, an advanced welding power supply that minimizes joint geometry and optimizes welding results. This technology allows for a reduced volume to be filled, resulting in significant cost savings and faster welds.

KEY FEATURES OF PIPE TITAN

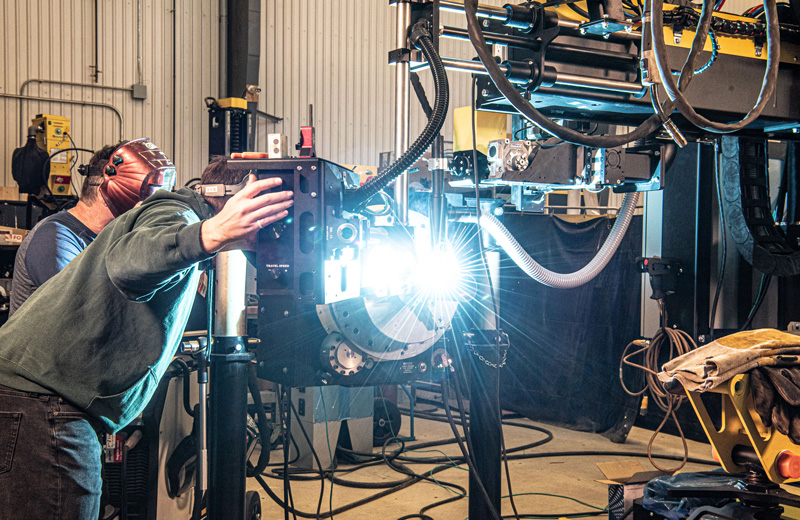

Non-Stop Hot-To-Cap Welding With One Manual/Mechanized Root Pass Required

Pipe Titan Welding System provides non-stop hot-to-cap welding with one manual or mechanized root pass required before switching to submerged arc for hot, fill and cap passes. Additonally, the top-flight tactile controls paired with thru-arc height tracking allow operators to have full control of the welding motion.