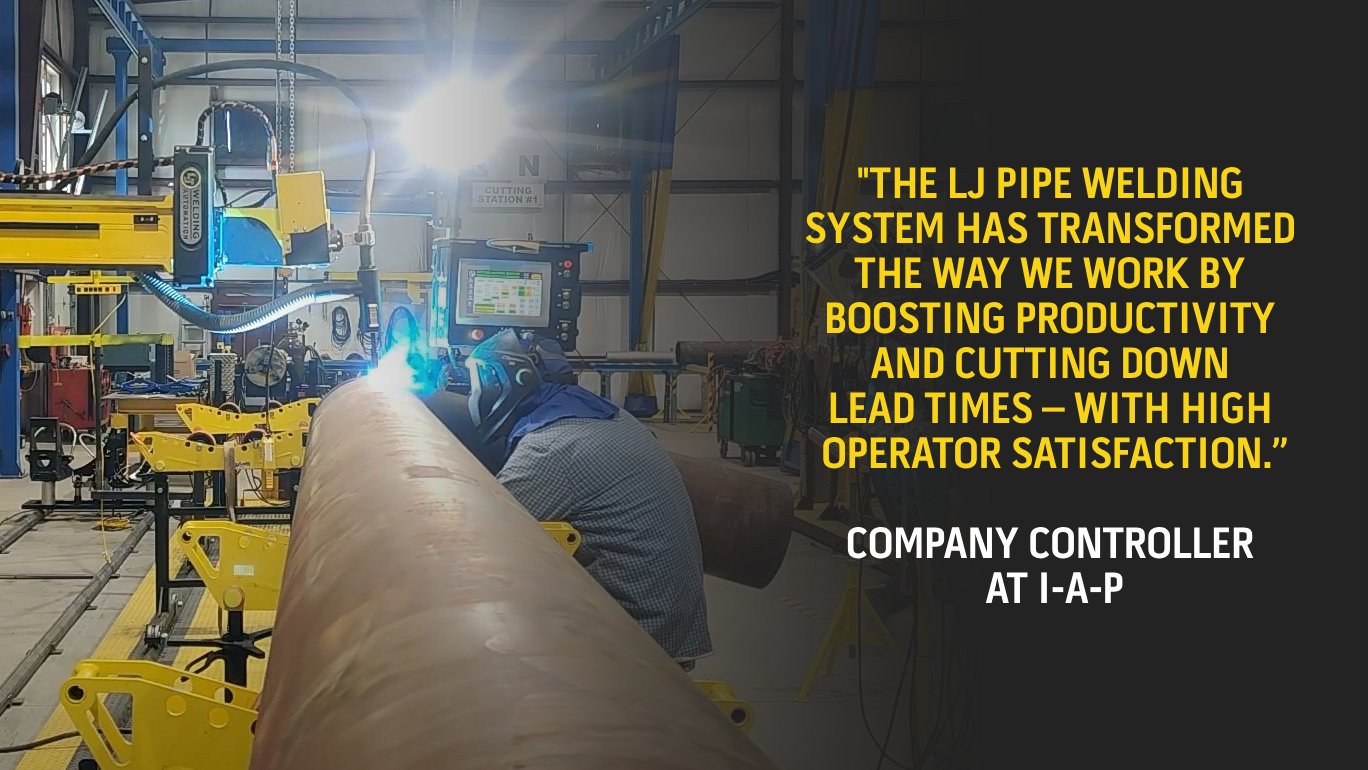

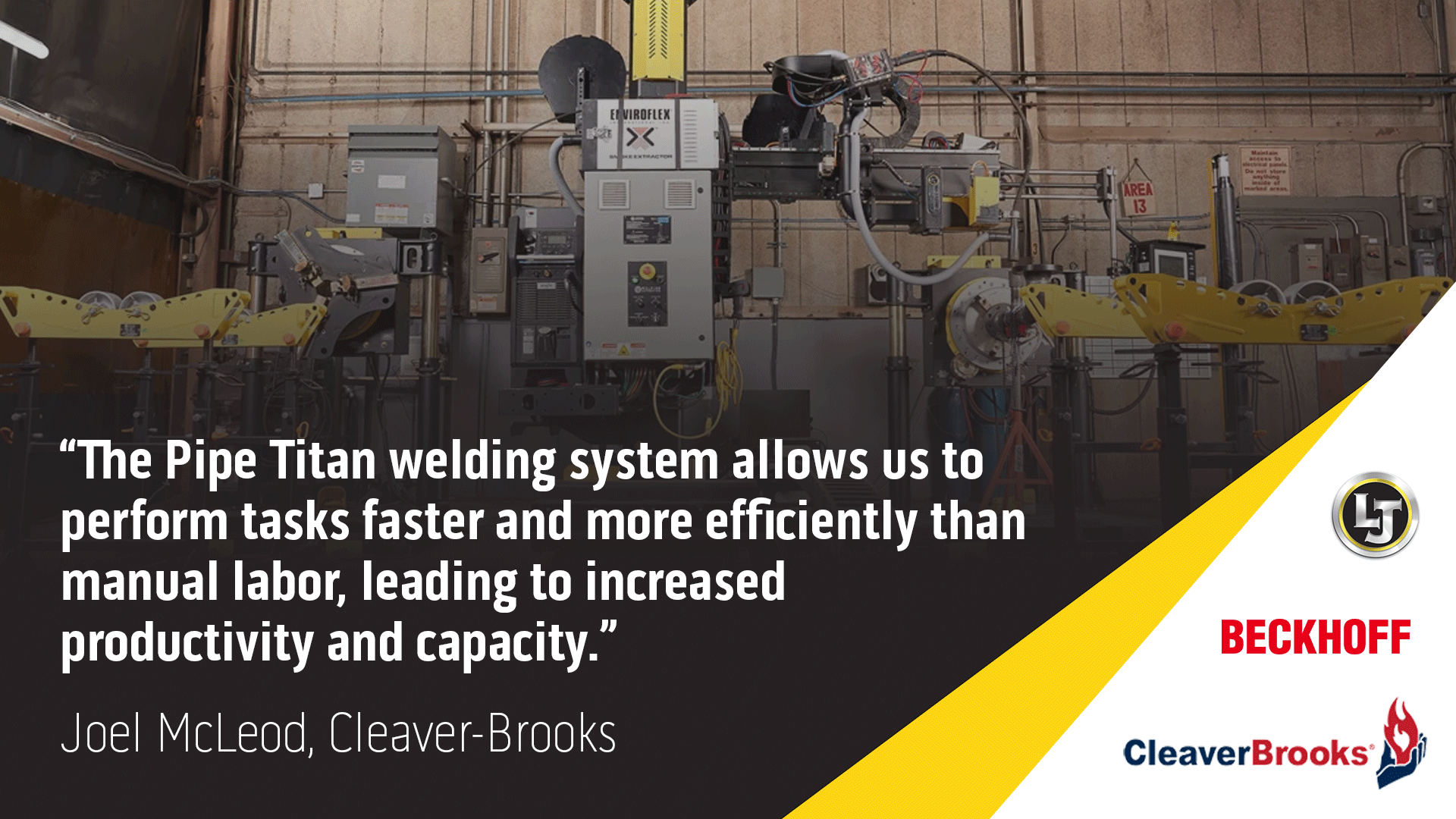

Improving Pipe Welding Productivity with LJ’s Automated Welding System

I-A-P Power & Process Ltd., a leader in the fabrication of pressure piping systems based out of Kamloops, BC in Canada, has built its reputation on precision, reliability, and high-performance delivery. Serving industrial clients where weld..

Continue Reading