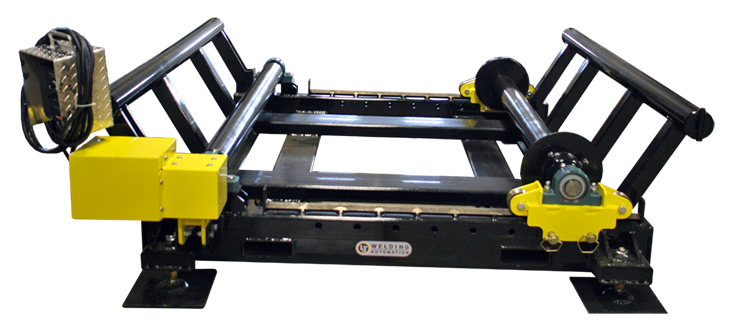

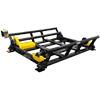

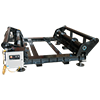

CABLE REEL ROLLERS

- LJ Cable Reel Rollers are used for powered assisting unwinding or payout of cable, and maximize productivity, worker comfort and safety.

|

Safety Catches: Prevents reels from falling off machine |

|

|

Slip Clutch: Protects drive train and maximizes safety |

|

|

Drive Rotation: Variable speed control, best in class drive train for max reel assist |

|

|

Reel Diameter: Pop pins and roller guides to easily adjust idler roller side for various diameters |

|

|

Leveling Feet: For leveling on uneven ground |

|

|

Side Guides on Rollers: Adjustable for various reel widths |

|

|

Frame: Extra heavy duty, rigid frames |

WHAT ARE CABLE REEL ROLLERS?

LJ Welding's cable reel rollers are a high-quality solution for managing and moving large cable reels in industrial projects. These rollers aid in handling, storing, and transporting long lengths of cable, making these procedures more efficient.

Smooth unwinding or payout of cable...

We offer a selection of 3 cable reel rollers including an array of safety features, the most notable of them being the embedded safety catches to prevent reels from falling off the machine. Built with top-grade materials, our pop pins and roller guides let operators easily adjust the idler roller side for various diameters and level it on uneven ground. By cutting down work time and enhancing worker safety, they ensure efficient results.

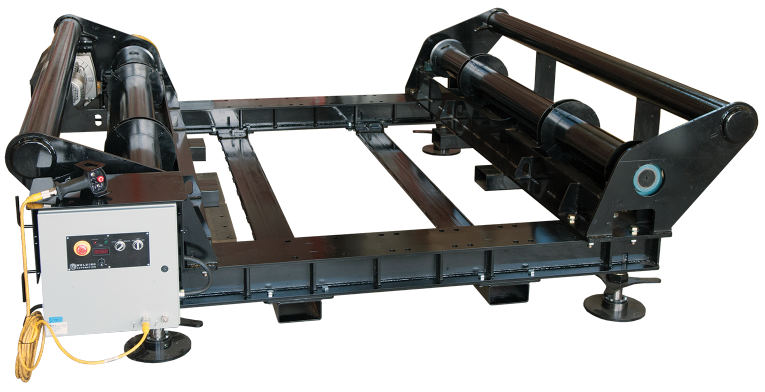

Our cable drum rollers also feature an easy-to-use and lightweight design, allowing operators to complete the work quickly and efficiently. With loading capacities that vary from 20,00 to 80,000 lbs (10-40 ton) and a turning speed of 2.5-47.5 RPM, they are perfect for demanding industrial environments. Additionally, LJ's cable reel rollers' highly durable design ensures long lifespan of the equipment.

Interested in our Cable Reel Rollers? Contact Us Today!

LJ'S CABLE REEL ROLLERS SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT CABLE REEL ROLLERS

What are the benefits of using cable reel rollers?

Cable reel rollers are used in many industries, including welding and construction. They provide an efficient way to transport large, unwieldy cables as they can be rolled up easily and reeled out smoothly. Cable reel rollers can reduce the strain of carrying heavy loads for long periods of time by providing a wheeled platform for easy movement. They also make it simpler to manage electrical projects that require multiple cables due to their high load-bearing capacity. Overall, cable reel rollers help with the safety of the workplace as they allow workers to quickly move dangerous wires without any manual lifting.

Are there any safety precautions I should take when handling and operating a cable reel roller?

Yes, it is important to take safety precautions when handling and operating cable reel rollers. Make sure you are wearing protective gear like gloves and safety glasses, as cables can become tangled or cause injury. The maximum load capacity of the roller should not be exceeded and all parts should be inspected regularly for signs of wear or damage before each use. The operator must always remain alert when using a cable reel roller to ensure that no one trips over the wires or falls due to a lack of stability from the rolling device.

Can cable reel rollers be used in wet or moist conditions?

It is not recommended to use cable reel rollers in wet or moist conditions as they may be prone to rust and corrosion. Moreover, the electrical wiring within a cable reel roller should not come into contact with water as this can cause damage to the wires and any connected equipment. It is always important to check that your cables are dry before using a cable reel roller in order for them to function correctly.

Side-By-Side Cable Reel Rollers Comparison:

| Specifications | |||

| Loading Capacity | 20,000 lbs (10-ton) |

30,000 lbs (15-ton) |

80,000 lbs (40-ton) |

| Footprint |

104-3/16” x 95-¾” x 29-¾” |

132” x 110” x 29-¾” |

142-5/8” x 140” x 42-½” |

| Spool Size Range |

OD: 24” - 96”, Roll Width: 63” Max |

OD: 24” - 144”, Roll Width: 96” Max |

OD: 60” - 192”, Roll Width: 120” Max |

| Tractive Effort | 880 lbs |

2,100 lbs |

8,500 lbs (Single drive) |

| Turning Torque | 2,200 in-lbs |

5,000 in-lbs |

To be added |

| Turning Speed | 2.5 - 47.5 RPM (30 - 750 in/min) |

3 - 30 RPM (48 – 480 in/min) |

3 - 19 RPM (48 – 480 in/min) |

| Height Range | 19-1/8”” - 22-1/8” (top of roller), Fine height adjustment |

26-3/16”” - 29-3/16” (top of roller), Fine height adjustment |

21-¼” - 24-¼” (top of roller), Fine screw height adjustment |

| Power Requirements | 220 V, 1-ph |

220V, 1-ph |

460V, 3-ph |

| Weight | 2,200 lbs |

3,015 lbs |

7,160 lbs |

| Brake Torque |

Adjustable slip clutch - consult LJ Welding for specifications |

Adjustable slip clutch - consult LJ Welding for specifications |

Adjustable slip clutch - consult LJ Welding for specifications |

| Controls | Variable Speed, Forward/Reverse AC Drive, optional foot or hand switches |

Variable Speed, Forward/Reverse AC Drive, optional foot or hand switches |

Variable Speed, Forward/Reverse AC Drive, optional foot or hand switches |