30–70% Higher Productivity

Achieve deposition rates up to 60 lbs/hour

Faster tower production, lower LCOE, and unmatched fabrication efficiency

Welding and material handling solutions for the most demanding industries

Reduced weld times on thick-wall wind towers and improved throughput by 30–70%

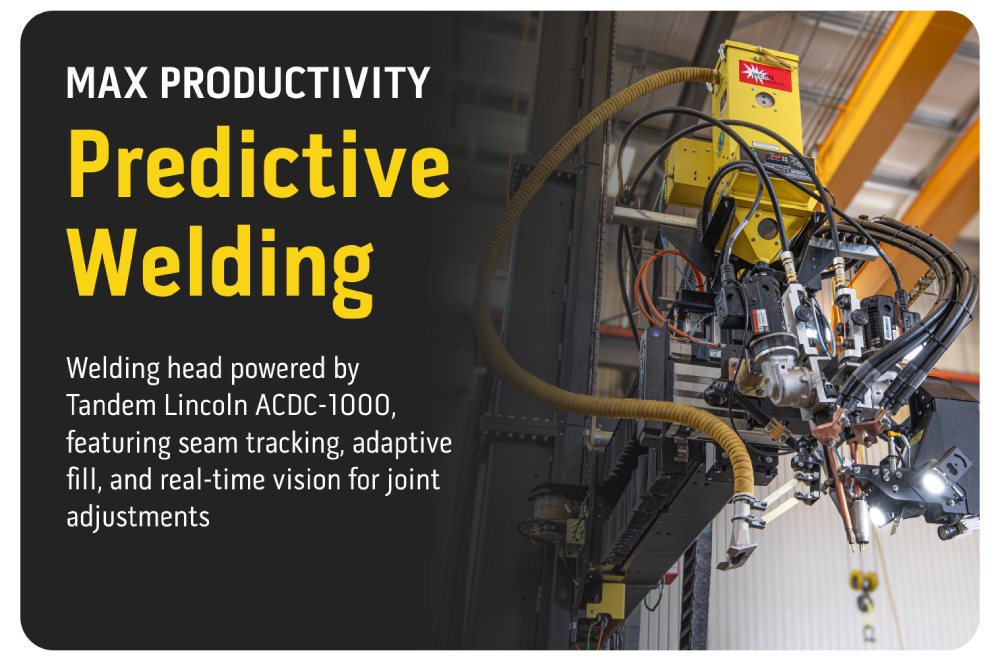

Customized and heavy-duty solutions for onshore applications, cutting-edge technology (Tandem SAW, Predictive Welding, HMI), and proven expertise in wind tower fabrication.

Achieve deposition rates up to 60 lbs/hour

Cut weld time, and reduce rework and labor costs

Align 100-ton, 4.3 m cans in under 30 minutes

Export WPS parameters directly into ERP/MES for full process tracking

Lower cost-per-unit through automation and protect profit margins

Automated long seam welding solutions built for high-volume, large-diameter tower sections.

Streamlined fit-up and high-speed girth welding for tower sections up to 100 tons.

Precision flange welding systems designed for fillet and circumferential welds, and repeatable QA results.

The demand for renewable energy is rapidly increasing, and with it, the need for efficient, reliable, and scalable solutions in wind tower fabrication has never been greater.

As wind turbines grow in size and complexity, fabricators face new challenges in handling large sections, ensuring precision fit-ups, and maintaining high productivity without compromising quality.

This is where LJ Welding Automation’s 100 Ton Growing Line + Predictive Tandem Subarc System comes in—an innovative welding system designed to meet the high demands of wind tower fabrication.

Less than 30 minutes using LJ’s hydraulic growing line, even for large-diameter, heavy-section towers.

Up to 60lbs/h with LJ’s Tandem Submerged Arc Welding (SAW) and Predictive Welding configuration.

Standard setups handle up to 4.3 meters for road-legal onshore tower sections. Larger diameters are possible using the stacked-shell welding method.

LJ Welding Automation’s award-winning research and development ensures that all products adhere to the highest international standards.