MIG WELDING BOOM

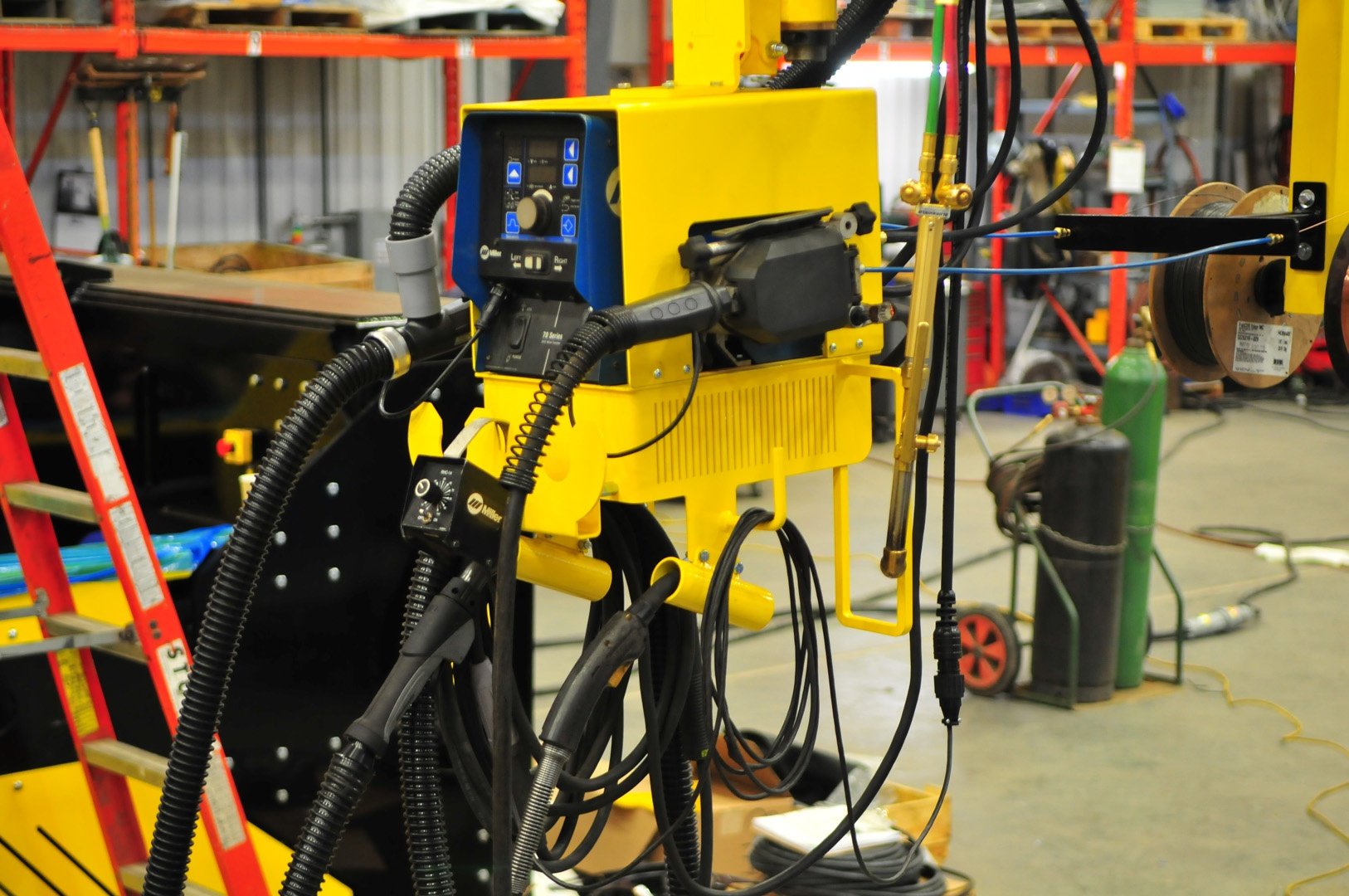

LJ’s MIG Welding Boom is a piece of machinery that offers a complete coverage of the welding area. Using our MIG Welding Boom helps to reduce non-arc time welding related activities, shop floor clutter and tripping hazards while keeping tools near arm's length.

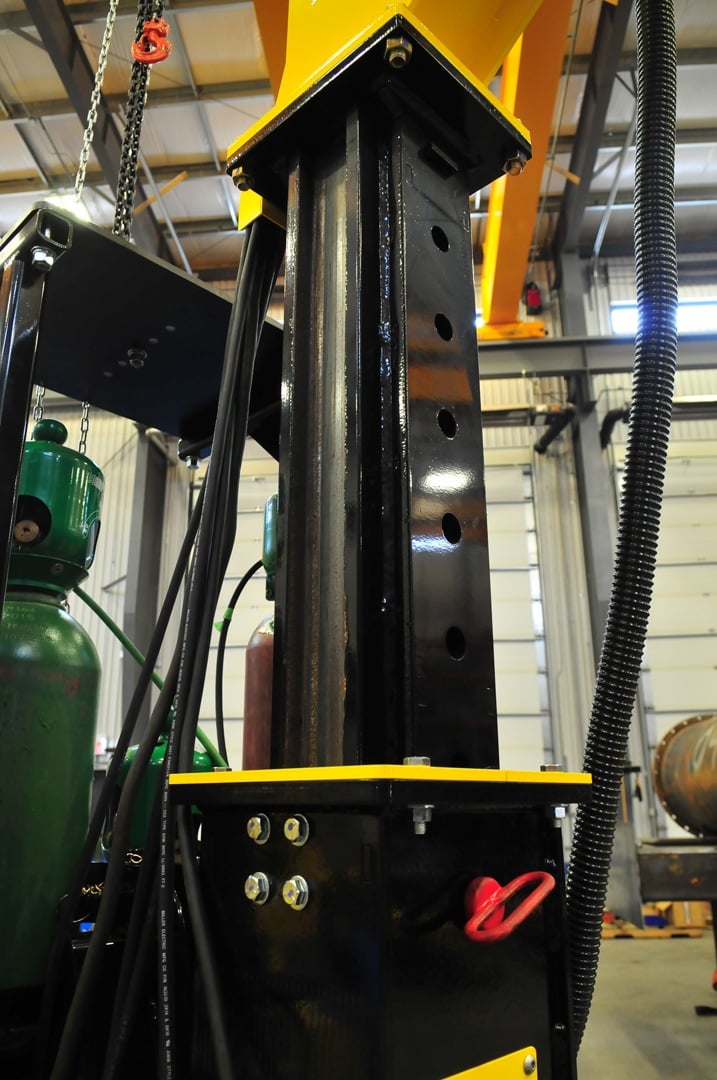

Our MIG Welding Boom comes with adjustable drag breaks which ensure complete control of the column rotation. Operators can take advantage of the pull and twist motion that allows for quick adjustments of a 16-foot working boom radius. Now your limited floor space can be optimized with no dead zones in the work area, giving your welders total coverage , reducing safety issues for operators. The MIG Welding Boom efficiently packs an increase to welders' safety, ease of use and a productivity boost while using less than two square yards of shop floor space. Lastly, our MIG Welding Boom minimizes distortion and decreases weld spatter and fumes, which results in less time spent on chipping, grinding and cleaning up the part.

The MIG Welding Boom comes with a standard area coverage of 16", however LJ also offers customization options to your shop's needs. MIG Welding Boom offers Max Working Height of 110" and Max Boom Height of 141". Its loading capacity goes up to 250 lbs. Furthermore MIG Welding boom makes an excellent addition to your existing turning roll system or shop's welding positioner space. It also integrates with any welding power source. Have your pneumatic-powered tools ready in one place with a 20-foot hose reel and up to 120 psi of compressed air.

If you are looking for a different piece of machinery, make sure to check the rest of our Accessories.