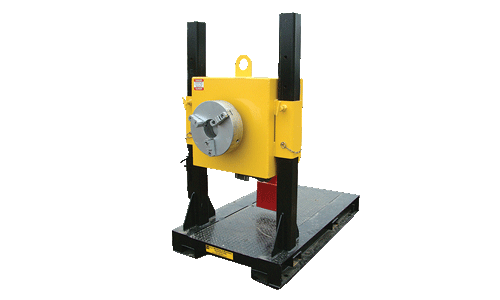

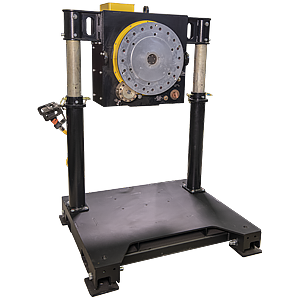

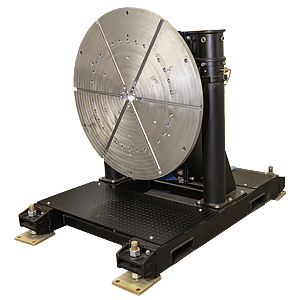

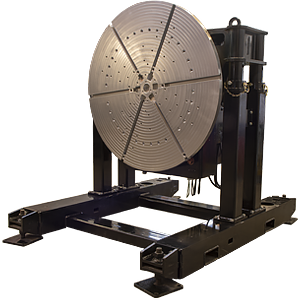

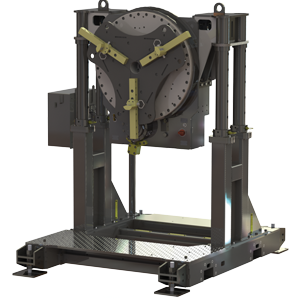

PIPE TURNING POSITIONERS

- LJ’s selection of Pipe Turning Positioners are used for positioning heavy-wall, large diameter pipe for spooling applications with large offset loads.

|

Lower Costs: Reducing start and stops while increasing the welding productivity of oddly shaped parts, resulting in lower costs related to welding |

|

|

Enhanced Weld Experience: Ensuring smoother control of the rotating movement along with enhanced stability and accessibility to significantly enhance welding quality |

|

|

Worker Ergonomics: 360° spin that allows a welder to stand in one position and constantly work on a level surface |

|

|

Welding Quality: LJ’s Pipe Welding Positioners ensure repeatable quality between batches and operators |

WHAT ARE PIPE TURNING POSITIONERS?

Pipe turning positioners are essential tools for ensuring the perfect alignment and rotation of pipes during welding operations. They offer a flexible and efficient solution for welding pipes of different sizes and shapes, providing a safe and stable platform for the welding process.

Our pipe turning positioners are designed with high-quality components, making them durable and long-lasting in even the most challenging welding environments. With a load capacity of up to 30 tons, they can handle pipes of different diameters and lengths with ease. LJ's pipe turning positioners are equipped with a range of features and capabilities, including adjustable rotation speeds, precise control over tilt angles, and advanced safety mechanisms to prevent any accidents during operation.

Consistent accuracy and welding results

Welders using our positioners can enjoy greater accuracy and consistency in their welding results, since they ensure a steady and constant speed of rotation, guaranteeing that the weld bead is uniform around the pipe's circumference. This significantly improves the weld's quality, strength, and overall integrity. The positioners also reduce fatigue associated with manually rotating heavy pipes, leading to a faster and more productive welding process.

These machines are suitable for use in various welding applications, including in the oil, gas, construction, and mining industries. They can rotate both horizontally and vertically, making them ideal for welding pipes that are mounted in tight or upside-down positions.

Interested in our Pipe Turning Positioners? Contact Us Today!

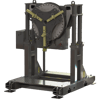

PIPE TURNING POSITIONER SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT PIPE TURNING POSITIONERS

How much load can the pipe turning positioner handle?

LJ's pipe turning positioners offer a load capacity of up to 30 tons, and are capable of handling pipes of different diameters and lengths with ease. Depending on the model chosen, the pipe turning positioner can also accommodate different weight limits. Our team is always available to assist customers in choosing the right size and capacity for their welding needs.

Do LJ's pipe turning positioners come with safety features?

At LJ Welding, we take our commitment to safety seriously. Our pipe turning positioners come equipped with advanced safety features such as emergency stop buttons, fault detection systems, and a fail-safe brake system. These features help prevent accidents, damage to equipment, and personal injury during welding operations.

What kind of customization options are available for pipe rotating positioners?

Our pipe turning positioners come with optional custom-built adaptations such as extended outriggers, fine lifting devices and precision tilting systems - all of which can be tailored to meet individual work requirements. With its robust construction, reliable performance and user-friendly control system,these machines are an ideal choice for those looking for welding solutions that offer maximum safety and efficiency.

What is the expected lifespan of a pipe turning positioner from LJ Welding?

The pipe turning positioners are built with high-quality components, making them highly durable and long-lasting. With its heavy-duty design and reliable performance, these positioners offer a lifespan of many years with properly maintained care.

Side-By-Side Pipe Turning Positioner Comparison

|

Specifications |

|||||||

| Loading Capacity | 3,000 lbs (at mounting plate) | 5,400 lbs (at mounting plate) | 3,000 lbs (at 12” overhung load) | 6,000 lbs (at 12” overhung load) | 12,000 lbs (at 12” overhung load) | 24,000 lbs (at 12” overhung load) | 60,000 lbs (at 12” overhung load) |

| Footprint | 72” x 43-⅛” x 77” | 72” x 43-⅛” x 77” | 89” x 76” x 118-⅜” | 67-¼” x 43-⅝” x 55” | 89” x 59-¼” x 72” | 96-½” x 72-⅜” x 78” | 133-½” x 96-½” x 105-3/16” |

| Turning Torque | 7,800 in-lbs (with counterweight) | 40,000 in-lbs | 20,000 in-lbs | 60,000 in-lbs | 125,000 in-lbs | 250,000 in-lbs | 800,000 in-lbs |

| Turning Speed | 0.3 - 3.0 RPM | 0.2 - 2.4 RPM | 0.2 - 2.7 RPM | 0.1 - 2.5 RPM | 0.05 - 2.2 RPM | 0.05 - 1.2 RPM | 0.04 - 0.8 RPM |

| Height Range | 45"- 69" (at mounting plate), adjustable in 4" increments | 44-⅝” - 68-⅝” (at mounting plate), Adjustable in 4” increments | 38” - 70” (at mounting plate), Adjustable in 4” increments | 34” - 70” (at mounting plate), Adjustable in 2” increments | 48” - 96” (at mounting plate), Adjustable in 3” increments | 48” - 96” (at mounting plate), Adjustable in 6” increments | 72-1/4” - 144-1/4” (at mounting plate), Adjustable in 8” increments |

| Mounting Plate Diameter | 15-⅞” (optional: 16” 3-jaw lathe style chuck available) | 26” (additional mounting accessories available) | 22-1/4” | 42” (T-Slot Plate with 6 x 5/8" slots) | 48” (T-Slot Plate with 6 x 3/4" slots) | 60” (T-Slot Plate with 6 x 1" slots) | 62-1/2” |

| Power Requirements | 120V, 15A, 1-ph, 60Hz | 208-240V, 12A, 3-ph, 60Hz | 120V, 15A, 1-ph, 60Hz or 208-240V, 9A, 1-ph, 60Hz | 480V, 5A, 3-ph, 60Hz | 480V, 11A, 3-ph, 60Hz | 480V, 11A, 3-ph, 60Hz | 480V, 31A, 3-ph, 60Hz |

| Ground Capacity | 400 Amps | 800 Amps | 800 Amps | 800 Amps | 1,500 Amps | 1,500 Amps | 1500 Amps |

| Weight | 1,820 lbs | 2,750 lbs | 1,782 lbs | 2,150 lbs | 5,000 lbs | 7,450 lbs | 20,462 lbs |

*Excluding gripper. Specifications subject to change; consult factory for all specifications.