WELDING COBOT TABLE SYSTEM

KEY SPECIFICATIONS

| Reach |

51.2 in (1300 mm) |

| Payload |

27.55 lb (12.5 kg) |

| Footprint |

60in x 48in x 96in |

| Weight |

1120lb (508kg) |

| Fixturing Table Size |

60" x 48" W/ 5/8" Tooling Dowel Holes |

| Travel Speed |

3.3 ft/s (1m/s) |

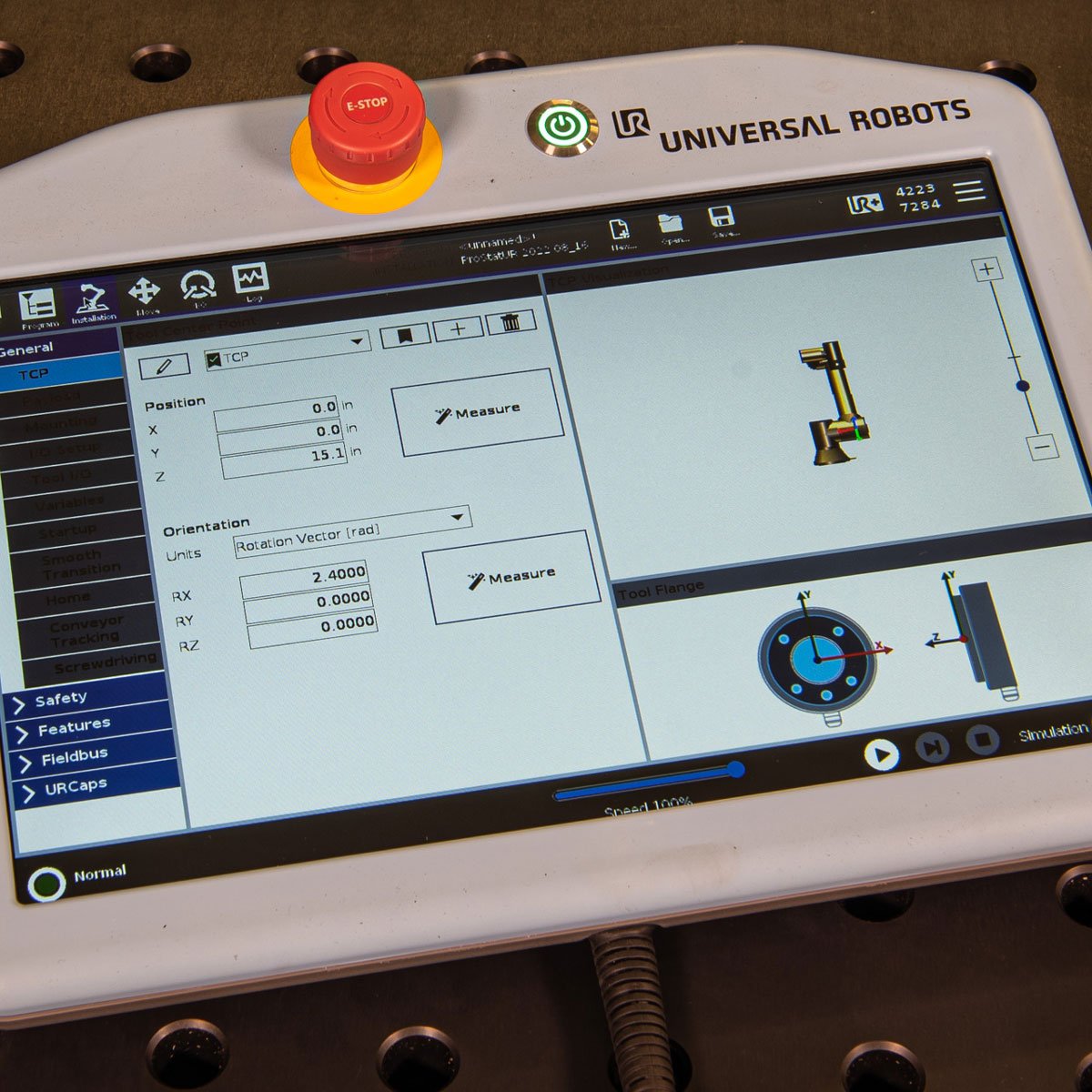

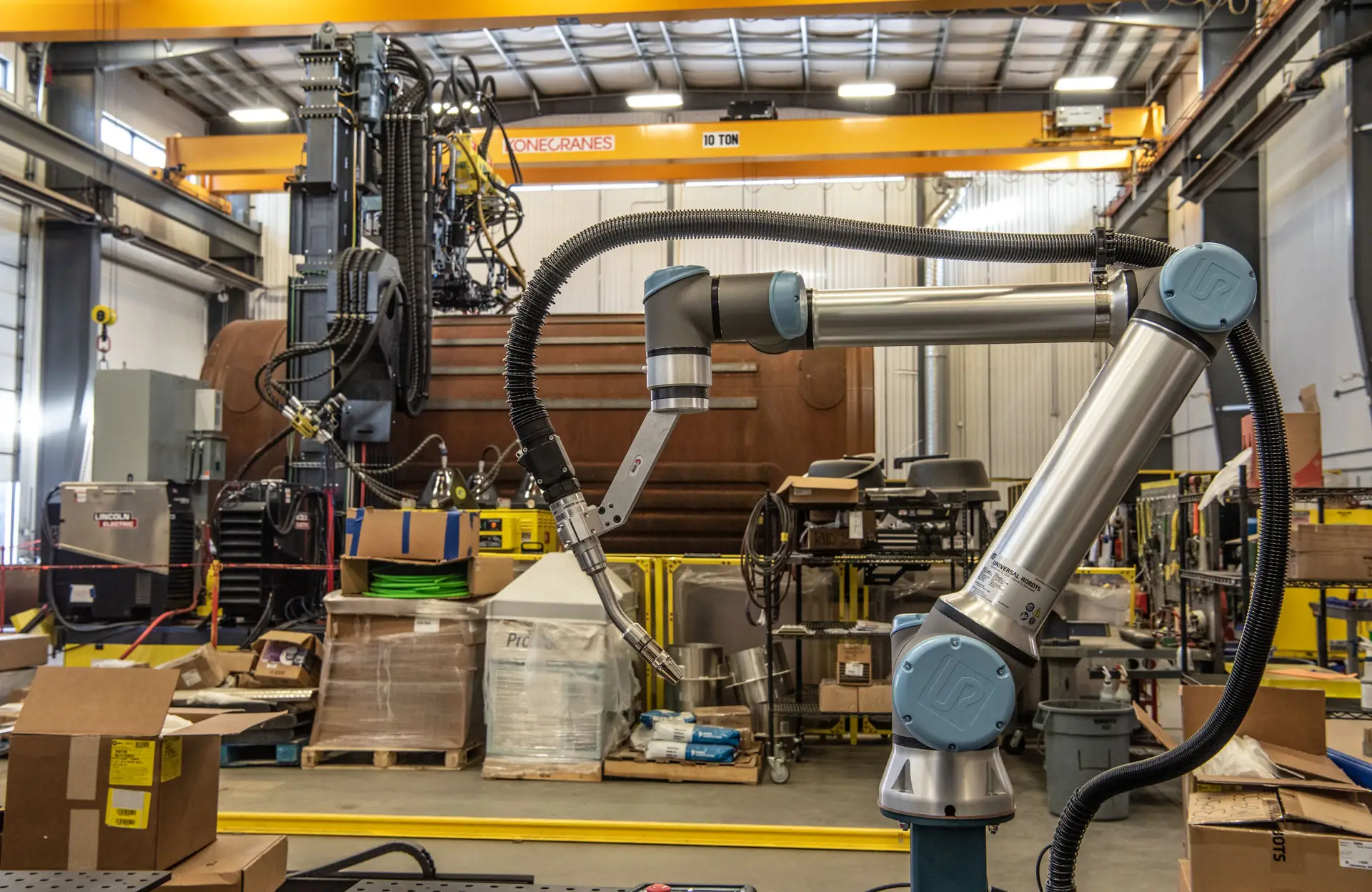

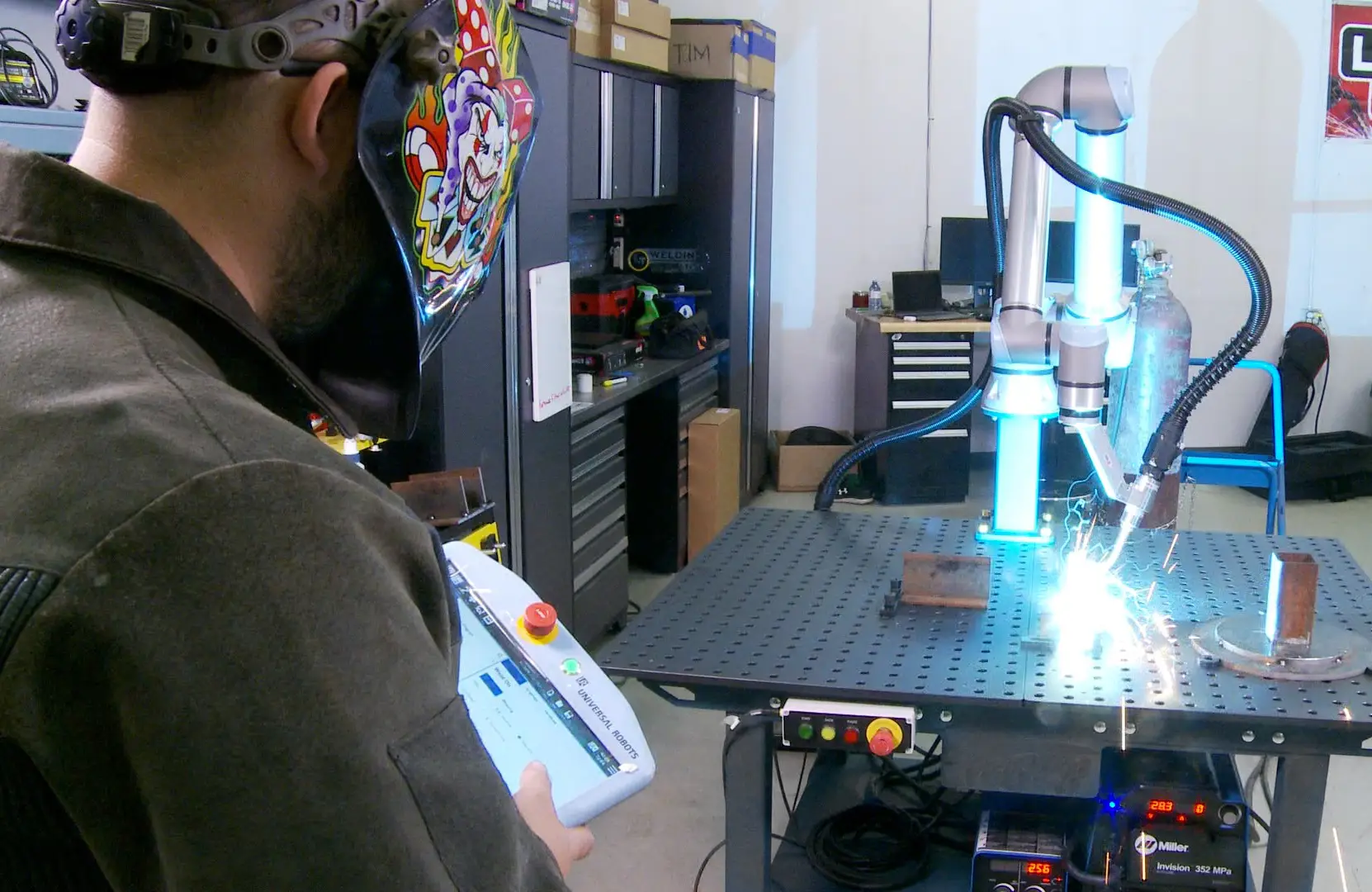

| Cobot |

Universal Robots UR10e |

| Power Source |

Miller Invision 352 MPA (Air-cooled) or Miller Invision 450 MPA (Water-cooled) |

| Power Requirements |

Cobot control panel: 120V, 15A, 60HZ Miller Power Source: 480V, 3-ph (Optional: 230V, 3-ph or 600V, 3-ph) |

| Safety |

Emergency Stop Integrated |

APPLICATIONS

The Welding Cobot Table System by LJ is a perfect fit for small manufacturers who need quick deployment, flexibility and ease of use at a low cost

TABLE FIXTURE OPTIONS

Basic Fixturing Kit: 66-pc Fixturing Kit, Fit 5/8 holes

Package Contents: The kit includes various Inserta, Clamps, Stops, Fasteners, Rests, and other essential fixturing elements.

Versatility: Designed for efficient clamping and fixturing, suitable for LJ's Welding Cobot Table System.

Applications: Ideal for welding, assembly, and other precision tasks.

Full Fixturing Kit: 149-pc Fixturing Kit, Fit 5/8 holes

Package Contents: This extensive fixture kit incluides various Inserta, T-Post Clamps, Ball Lock Bolts, Riser Blocks, a Mountain Base and other essential fixturing elements.

Versatility: Engineered for efficient clamping and fixturing, compatible with LJ's Welding Cobot Table System.

Applications: Ideal for welding, assembly, and other precision tasks.

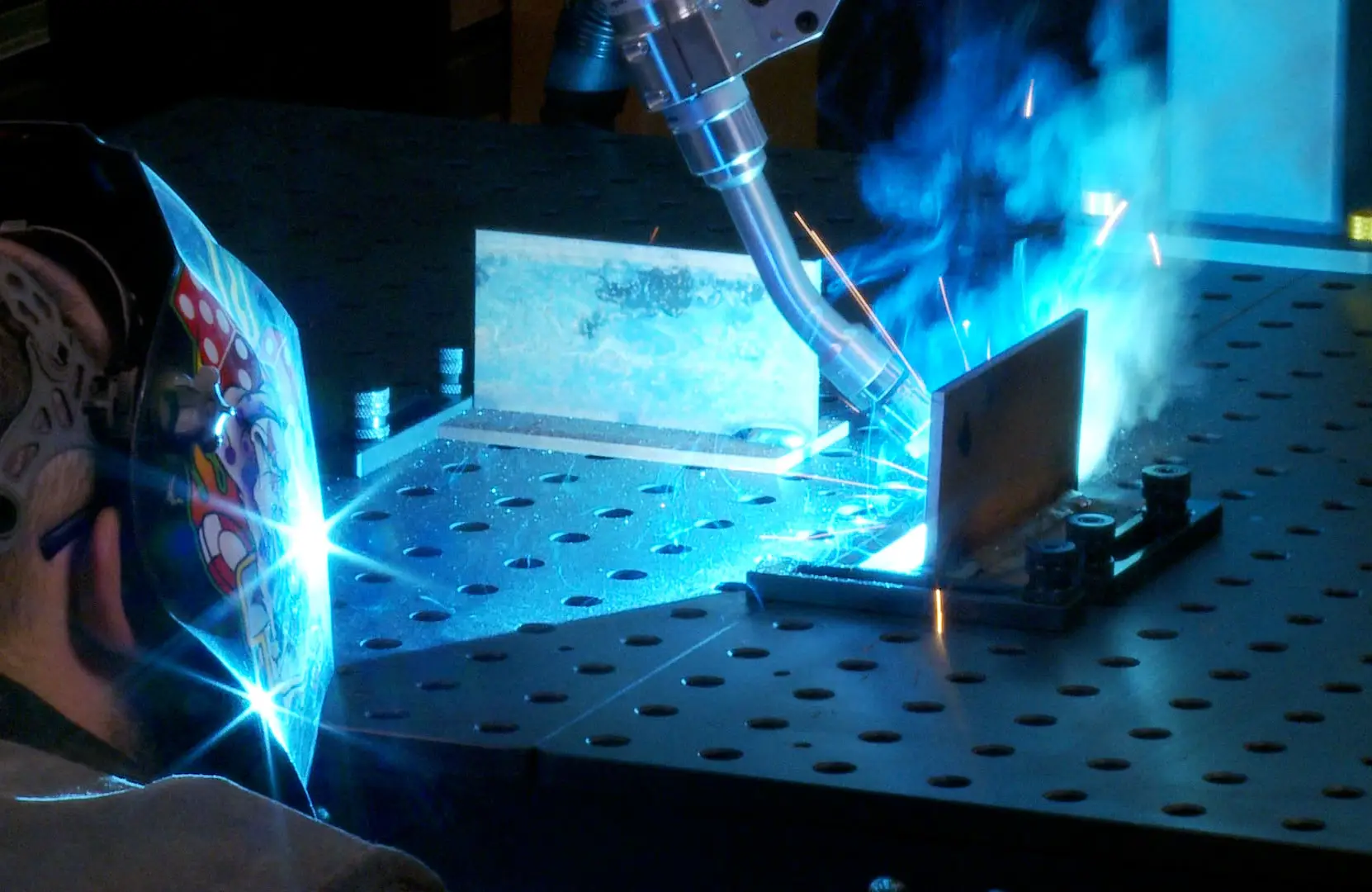

KEY BENEFITS OF COBOT WELDING

Ideal for Small Volume & High Mix Applications

Easy to Set Up & Program with Minimal Training Required

Flexible & Easily Deployed in any Environment

Reduce Inventory Costs by Eliminating Costly Tools

Reduce Labour & Eliminate Repetitive / Dangerous Tasks

Built-in Safety Features Ensuring Workers' Well-Being

Provides a More Productive and Safer Work Environment

Easy to Relocate in Shop to Improve Productivity & Workflow

Easy Reprogramming of the Cobot to Weld Different Parts