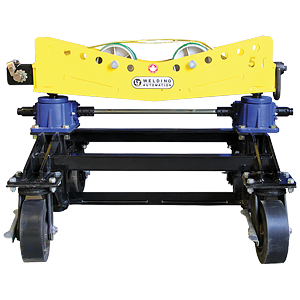

WELDING PIPE STANDS, TRIPODS & PIPE SUPPORT STANDS

- LJ’s Welding Pipe Stands are used for rolling and supporting pipe, and handling pipe safely and efficiently. LJ pipe stands are typically used as rolling pipe supports in conjunction with welding positioner and column and boom manipulator applications.

| Height Adjustability: The height adjustability on our pipe stands ensures smooth transitions even when the pipe support is under a load. This allows welders to raise or lower the pipe to the same level as the machine and avoid human factor failures | |

| Pipe Support: Our welding pipe roller stands can be used to only support pipes when rolling is not required. This allows all worked on pipes to be staged in one location, keeping the fusion machine stationary and minimizing the downtime between fusion joints | |

| Increased Productivity: LJ’s Welding Pipe Stands provide optimal solutions to welding applications on-site maximizing production, improving fusion processes and reducing tear and wear | |

| Smooth Rotation: Our pipe stands also come with urethane rolling wheels with lubricated fittings that allow smooth and safe rotation of pipes and materials for welding fabrication | |

| Worker Safety: Using our pipe stands results in reduced tear/wear on machinery and strain produced on operators |

WHAT ARE WELDING PIPE STANDS?

LJ's Welding Pipe Stands are designed with high quality materials to ensure durability and reduce wear/tear, enabling them to support heavy workloads. One of the unique features of our stands is they can be used to only support pipes when rolling is not required. This allows all worked on pipes to be staged in one location, keeping the fusion machine stationary and minimizing the downtime between fusion joints.

Wide range of applications for pipe rolling and support

These stands can be used in a range of applications, designed to accommodate different pipe sizes with adjustable height, which is convenient for handling different pipes having varying width and weight. The tripod design of these stands makes them easy to move around and place wherever you need them, while the jack stands feature four legs providing an even more sturdy and solid base.

Interested in our Welding Pipe Stands? Contact Us Today!

LJ'S PIPE STANDS SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT WELDING PIPE STANDS

What is the function of a pipe stand for welding?

A pipe stand for welding is used to securely hold pipes in place during welding operations. They allow welders to adjust the height and angle of the pipe, making it easier to access places to reach when welding. The legs of some models can be reversed, allowing them to fit onto a variety of pipe sizes without having to purchase multiple stands. This makes them an ideal choice for welders who need a flexible solution for their welding applications.

How do I determine which type of stand is best for my project?

Choosing the best type of stand for a given project depends on the size, weight, and application of the item being lifted. LJ Welding offers a variety of stands that are adjustable and can support heavy loads in a variety of settings. The Modular Roller Support is designed to be used with pipes and other cylindrical objects like tanks, while the Jack Stands have a higher load capacity and can be adjusted to fit different heights. Generally speaking, if you need an adjustable stand which can handle heavier weights then the Jack Stands are your best option but if you need more flexibility then consider using Modular Roller Supports instead.

What kind of maintenance is necessary for LJ's pipe welding stands?

Proper maintenance of Pipe Stands requires periodic inspection of all parts and components to ensure they are in good working condition. If any damage is found, the part should be replaced immediately. All moving parts should be properly lubricated and cleaned regularly with a non-petroleum based cleaner.

The supports should also be checked for wear or deterioration over time and any uneven surfaces or sharp edges should be smoothed out or filed down before use. It is also important to keep the support free from debris such as oil, dust, rust, and dirt to avoid corrosion and ensure maximum product life. Most importantly, it's essential to follow the manufacturer's instructions for correct usage of each product type in order to maximize safety benefits when using these stands.

Side-By-Side Modular Roller Support Stands Comparison

| Specifications | ||||

| Loading Capacity | 4,000 lbs (2-ton) | 4,000 lbs (2-ton) | 8,000 lbs (4-ton) | 16,000 lbs (8-ton) |

| Footprint | 34" x 36-1/2" x 39" | 30-3/8" x 24-1/2" x 36-3/4" | 36" x 50" x 29" - 42" | 43” x 55-⅛” x 28-⅞” |

| Diameter Range | 2" – 48" | 2" – 48" | 4" – 48" | 8" – 60" |

| Height Range | 38-1/2" - 64-5/8" (top of wheel), Adjustable in 3-1/8" increments & fine height adjustment |

24" - 37-3/4" (top of wheel), Fine height adjustment |

30"- 42" (Dual screw jack geared height adjust) | 28-⅛” - 40-⅞” (top of wheel), Fine screw height adjustment |

| Weight | 186 lbs | 147 lbs | 450 lbs | 612 lbs |

Side-By-Side Jack Stands & Tripods Comparison

| Specifications | ||||||

| Loading Capacity |

4,000 lbs (2-ton) |

10,000 lbs (5-ton) | 2,500 lbs (1.25-ton) | 5,000 lbs (2.5-ton) | 5,000 lbs (2.5-ton) | 5,000 lbs (2.5-ton) |

| Footprint | 24-7/8" x 37-1/8" x 27-15/16 | 28-1/2" x 42-3/8" x 29-1/4" | 20-7/8" x 30-1/2" x 28" | 20-¾” x 24” x 20-15/16” | To be added | To be added |

| Diameter Range | 2" - 36" | 4” - 48” | 2” - 28” | 2⅜” - 28” | To be added | To be added |

| Height Range |

27-1/4" - 41-1/2" (top of wheel), Fine screw height adjustment |

27-1/4" - 42" (top of wheel), Fine screw height adjustment |

20-3/4" - 34-7/8" (top of wheel), Fine screw height adjustment |

16” - 24-⅝”, Adjustable in 2-1/2" increments & Fine height adjustment | To be added | To be added |

| Weight | 197 lbs | 438 lbs | 197 lbs | 38 lbs | To be added | To be added |