BEAM CLAMP ROLLERS

-

Beam clamp rollers are vital tools for installing pipes in the industrial sector. LJ offers a range of specialized lightweight models with beam clamps that enable quick setup and customizable roller heads to ensure efficient, safe installation every time

|

Protect Pipe Coating: Our equipment keeps your piping installation safe while crossing dangerous terrain, like rivers and roads. Its protective coatings reduce drag forces so you can focus on the job at hand with confidence |

|

|

Worker Safety: Worker safety is paramount, and our beam clamp rollers heavy materials can be safely maneuvered within a job site – promoting efficiency without compromising the wellbeing of workers. |

|

|

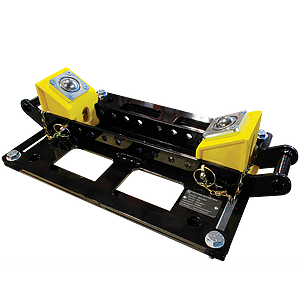

Increase Loading Speed: With LJ's Multi-Directional beam clamp rollers, the loading process for modular construction pipes can be swift and efficient - ensuring your project is always on track |

WHAT ARE BEAM CLAMP ROLLERS?

Our beam clamp rollers are an efficient tool for securely and quickly installing pipes, making them an excellent addition to your worksite. Not only can they handle heavy materials with precision but they also allow our customers to move securely held objects across structural steel beams without compromising the safety of workers.

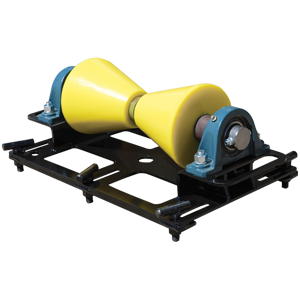

In terms of design features, our fixed beam clamp rigging rollers have an outer coating for maximum exterior protection to your pipes during crossing installation processes, even in challenging environments like rivers or roads.

Fast pipe installation and reuced crane use...

Our beam clamp rollers can help reduce crane time by up to 40%, while providing a safer and more comfortable installation experience allowing you to save valuable time. This way, our customers can streamline the installation process, keeping projects on schedule and increasing efficiency while at the same time reducing risks.

Interested in our Beam Clamp Rollers? Contact Us Today!

BEAM CLAMP ROLLERS SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT BEAM CLAMP ROLLERS

How do beam clamp rollers improve safety on the worksite?

Beam clamp rigging rollers are a key safety device used in workplaces to secure beams and other large objects during lifting, transport and storage operations. They help keep the beam or object stable, reduce the risk of accidents, limit potential damage to equipment, wires and other surrounding items. Beam clamp rollers also improve ergonomics by reducing fatigue since the load can be safely moved on its own wheels with less effort from the operator.

What is the maximum load capacity of LJ's beam clamp rollers?

The maximum load capacity of an LJ Welding beam clamp roller will depend on the type of clamp roller you have, the loading capacity we offer ranges from 2000 to 20000 lbs (1-9 tons). It is always important to check that all components are securely connected and ready for use before use to minimize accidents.

Can beam clamp rollers be used for both horizontal and inclined applications?

Yes, beam clamp rollers can be used for both horizontal and inclined applications. Beam clamp rollers are suitable for use on a variety of surfaces ranging from flat to severely curved and the design is versatile enough for use in both horizontal or vertical positions. The beam roller chain allows the roller to move along a track which enables it to travel up an incline as well as horizontally.

Side-By-Side Unidirectional Beam Clamp Rollers Comparison

|

Specifications |

|||||

| Loading Capacity | 2,000 lbs (1 ton) | 2,000 lbs (1 ton) | 4,000 lbs (2 ton) | 10,000 lbs (5 ton) | 20,000 lbs (10 ton) |

| Footprint | 19-¾” x 11” x 5-7/16” | 20” x 26-¾” x 8-9/16” | 18-⅛” x 25-¾” x 9-11/16” | 19-⅛” x 30-9/16” x 7-⅛” | 19-⅛” x 49-⅜” x 12-½” |

| Diameter Range | 2” - 12” | 2-3/8” - 24” | 2" – 16" | 2" – 42" | 16” - 60” |

| Rolling Surface | V-style roller mounting, 3” OD Urethane side rollers (x2) | Conical style 7-½” OD Urethane roller (x2) | V-style roller mounting, 6” OD Urethane side rollers (x2) | V-style roller mounting, 4-1/4” OD Urethane side rollers (x2) | V-style roller mounting, 6-3/8” OD Urethane side rollers (x2) |

| Beam Clamp Flange Size Range | 6” - 12” Wide x 1/2” - 1-¼” Thick | 5” - 12” Wide x 1/4” - 1-3/4” Thick | 5” - 13” Wide x 1/4” - 1-3/4” Thick | 6” - 12” Wide x 1/4” - 1-3/4” Thick | 5” - 12” Wide x 3/8” - 1-1/4” Thick |

| Weight | 43 lbs | 94 lbs | 98 lbs | 95 lbs | 250 lbs |

Side-By-Side Multi-Directional Beam Clamp Rollers Comparison

|

Specifications |

|||

| Loading Capacity | 2,000 lbs (1 ton) | 2,000 lbs (1 ton) | 4,000 lbs (2 ton) |

| Footprint | 19-⅜” x 9 x 5-1/16” | 18” x 27-⅜” x 5-15/16” | 20-⅛” x 25-¾” x 6-⅜” |

| Diameter Range | 2” - 8” | 2" - 24" | 4" – 36" |

| Rolling Surface | Multi-Directional Roller | Multi-Directional Roller | Multi-Directional Roller |

| Beam Clamp Flange Size Range | 6” - 12” Wide x 1/4” - 1-3/4” Thick | 4” - 12” Wide x 1/4” - 1-3/4” Thick | 5” - 12” Wide x 1/4” - 1-3/4” Thick |

| Weight | 40 lbs | 60 lbs | 80 lbs |