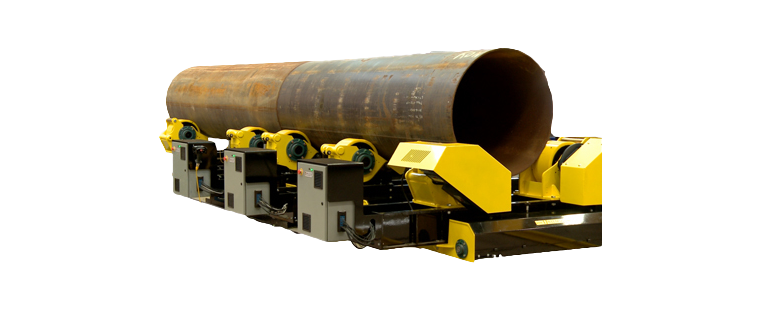

TURNING ROLLS: GROWING LINE SYSTEMS

- LJ specializes in an innovative growing line system used for fast alignment, leveling, fit-up and indexing of large pipes, tanks and vessels with weight capacity up to 100 tons and 20ft diameter.

|

Quick Indexing: The fast-fit growing line makes alignment, leveling, fit-up and indexing an efficient one-man job |

|

|

Increase Productivity: Growing lines can reduce fit up time by up to 65% when compared with traditional methods and maximize operator safety |

|

|

Fast Fit-Up: With our fast-fit up growing line systems you can fit up and tack your tanks in under 45 minutes |

|

|

Safety: LJ’s fast-fit growing line system ensures the material handling process is much safer and more reliable and easily repeatable |

|

|

Minimize Crane Use: With our fast fit-up growing lines, you’ll be able to minimize crane use, and instead load the tank segments and let the growing line fit-up bed do the rest |

LJ'S GROWING LINE SYSTEMS SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT GROWING LINE SYSTEMS?

What are tank & vessel fit-up growing line systems, and how do they work?

A tank & vessel fit-up growing line system is an advanced set of machinery designed to automate and enhance the efficiency of assembling large cylindrical structures like tanks and vessels.

By using adjustable rollers and alignment tools to position, rotate, and hold cylindrical sections in place, growing line systems enable precise welding and assembly. This system can adjust to accommodate various diameters and lengths, making it versatile for different project requirements.

What are the key benefits of using a growing line system for tank and vessel assembly?

The key benefits include significantly increased assembly speed, improved weld quality due to precise alignment, reduced labor costs through automation, and enhanced safety for workers by minimizing manual handling.

In our experience, the growing line systems for fit-ups can decrease the cycle time of old systems at peak operation by 50%, with existing workers used for more productive needs. See more information here.

The growing lines also enable increase in overall welding throughput by increasing the welding speeds while maintaining or increasing the weld quality. See our case study here.

Can the growing line system handle different sizes and types of tanks and vessels?

Yes, all of our growing line systems are designed with adjustability in mind, capable of accommodating a wide range of diameters and lengths.

The capabilities of our growing lines differ from model to model, with the diameters ranging from 72” up to 240” with a custom option. See more of the specifications below. If you are interested in Growing Lines with custom specifications, feel free to contact our sales team.

How does the implementation of a growing line system impact the welding process?

The growing line system enhances the welding process by providing stable and precise positioning of the parts to be welded, improving weld seam accessibility, and allowing for continuous welding operations. This results in higher-quality welds, reduced weld defects, and a more streamlined workflow, significantly impacting overall productivity.

Especially in the tank & vessel fabrication, the growing lines systems help decrease pipe joining times by 50%. See our case study here.

Side-By-Side Growing Line Systems Comparison

| Specifications | ||||||

| Load Capacity | 80,000 lbs (40-ton) | 40,000 lbs (20-ton) | 120,000 lbs (60-ton) | 80,000 lbs (40-ton) | 120,000 lbs (60-ton) | 200,000 lbs (100-ton) |

| Diameter Range | 70" - 150" | 48" - 186" | 240" - 240" | 24" - 216" | 24" - 216" | 24" - 240" |

| Minimum Workpiece Length | Determined by track lenght | 60" | Determined by track lenght | 144" | 144" | 144" |

| Rotation Speed | 8 - 120 in/min | 10 - 150 in/min | 5 - 120 in/min | 5 - 50 in/min | 5 - 50 in/min | 5 - 50 in/min |

| Track Drive Speed | 60 - 360 in/min | 48 - 480 in/min | 5 - 65 in/min | 12 - 120 in/min | 12 - 120 in/min | 12 - 120 in/min |

| Input Power | 480V, 3-Ph, 60Hz, 15A | 480V, 3-Ph, 60Hz, 15A | 480V, 3-Ph, 60Hz, 15A | 480 V, 3-Ph | 480 V, 3-Ph | 480 V, 3-Ph |

| Optional Extras For Fully Automated System | Column & Boom Welding Manipulator | MNX-100 Subarc Manipulator | Column & Boom Welding Manipulator | Column & Boom Welding Manipulator | Column & Boom | Welding Manipulator |