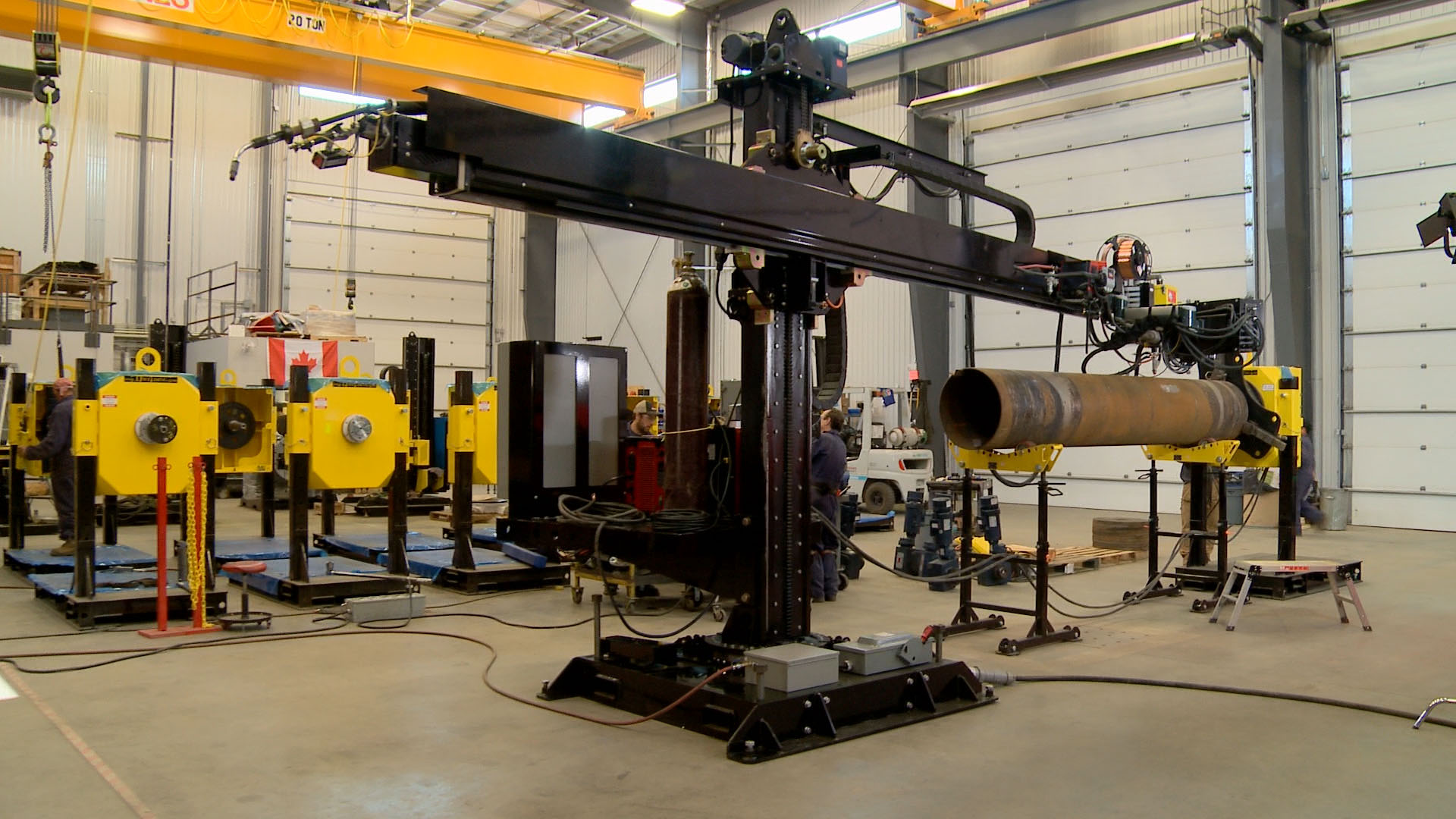

Pipe Mill Invests in LJ Inside Diameter (ID) SAW System

A steel pipe mill has invested in LJ’s small bore, inside welding system. This pipe mill needed a submerged arc welding (SAW) process that could weld inside of pipe down to 24” diameter, and with a reach of up to 50ft (15m) inside which required..

Continue Reading