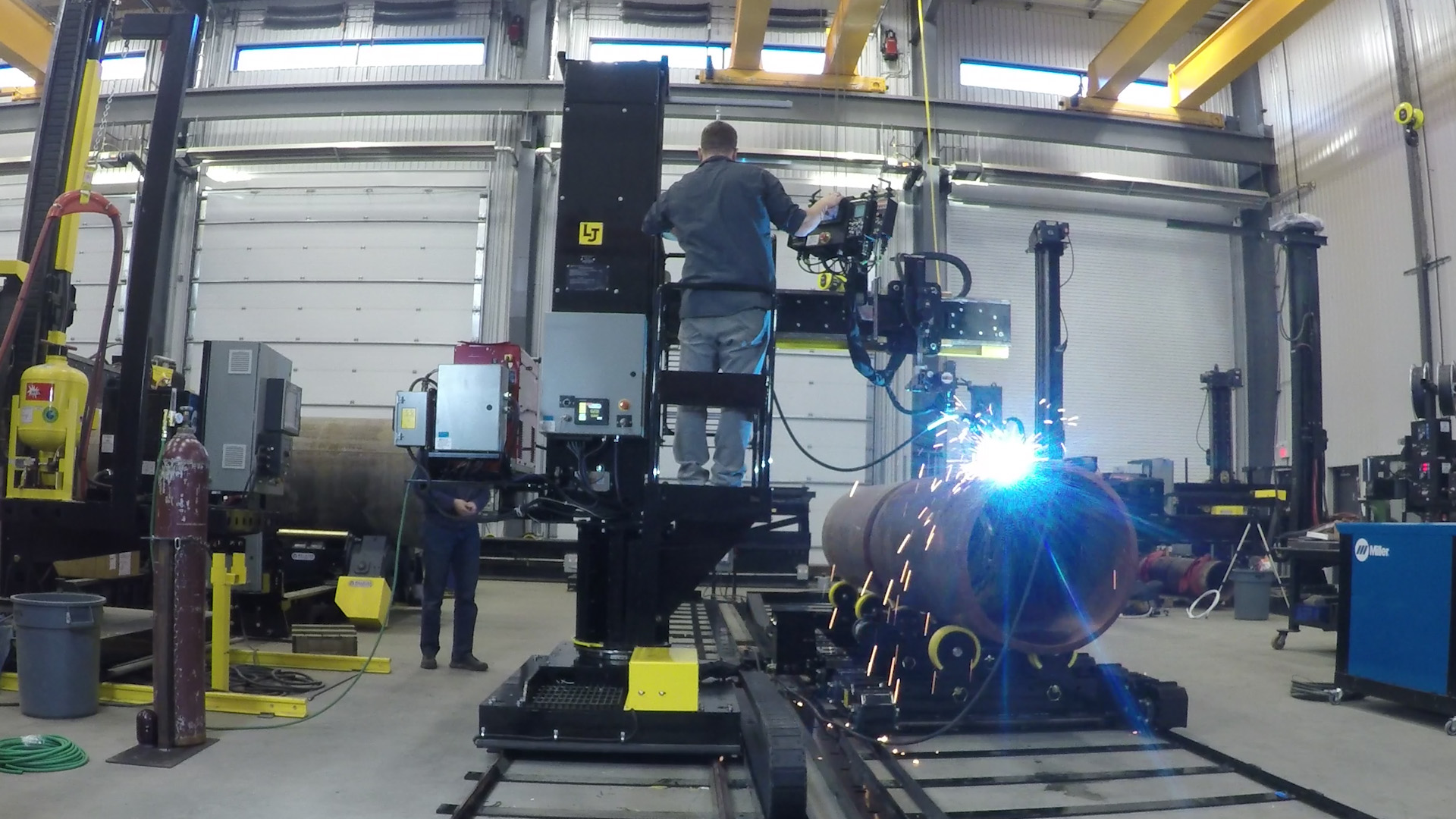

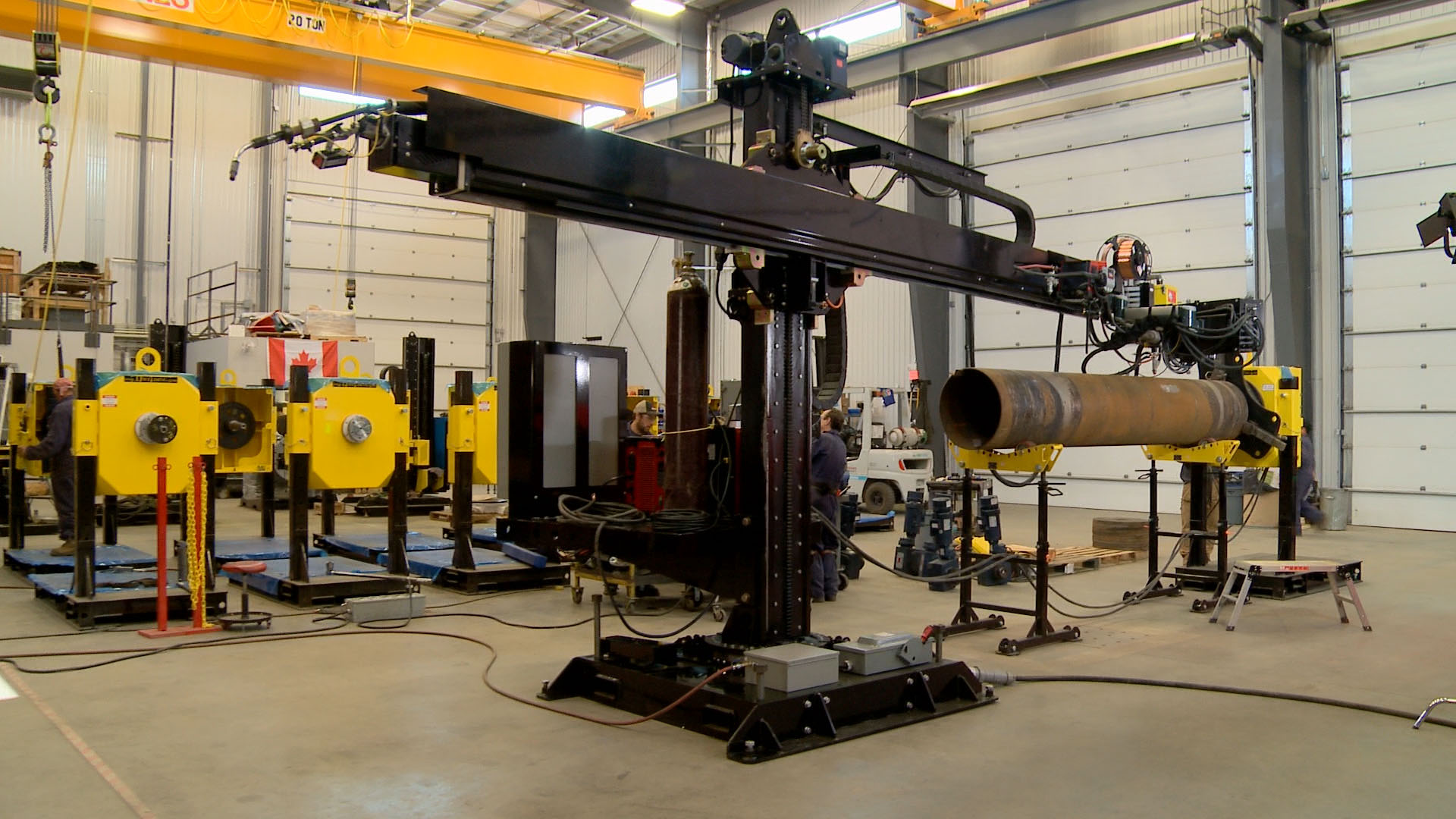

In-House Subarc Cladding System Hacks Major Expense For Pipe Mill

Situation

A steel pipe mill had been outsourcing a hard surfacing (cladding) application for one of their highest use wear parts, an hourglass shaped steel roller. The customer needed to lower their costs, and explore savings opportunities by..

Continue Reading