PIPELINE ROLLER EQUIPMENT: PIPELINE ROLLERS

- Pipeline rollers are designed to protect, support, and guide a pipeline section during river and road crossings while minimizing drag forces of pipe-pulling through horizontally drilled or bored holes.

| Modular Design: LJ’s pipeline rollers provide a modular design allowing to execute curved pulls, and its convenient lightweight ensures that it can be easily lifted with chains, straps or forks | |

| Worker Ergonomics: Using our pipeline rollers make the process of handling and rolling easier, time-saving and essentially reduce the strain on operators | |

| Increased Productivity: Our pipeline rollers help the site to run more efficiently which increases productivity and profitability as well | |

| Smooth Rolling: This equipment ensures smooth and safe rolling that keeps the pipes above the ground, away from any dirt or anything else that could cause damage to it |

WHAT ARE PIPELINE ROLLERS?

LJ Weldings pipeline rollers are an outstanding tool of our pipeline equipment used in pipeline installations to facilitate the transportation and movement of heavy pipes. These rollers are lightweight and designed to provide a stable and smooth surface for the pipeline to move across during installation.

We have five different models of pipeline rollers available in various sizes that can withstand loads ranging from 1 ton to 40 tons. All our rollers are made from high-quality materials to ensure their durability and efficiency.

Enhance worker ergonomics & productivity...

LJ Welding selection of heavy duty pipeline rollers not only provide a stable and smooth surface for pipes during installation, but they also enhance worker ergonomics and productivity by reducing physical strain on workers and allowing them to easily move heavy pipes from one location to another.

The ergonomic design of these rollers significantly improves worker safety by reducing the risk of job-related injuries. At LJ Welding, we prioritize our workers' wellbeing, which is why the pipe heights are kept at a comfortable level, ensuring that they do not experience back strains or other injuries. The rollers' lightweight design and ease of maneuverability also allow workers to position pipes quickly without the aid of heavy machinery or additional labor, leading to faster installation time.

Interested in our Pipeline Rollers? Contact Us Today!

PIPELINE ROLLERS SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT PIPELINE ROLLERS

How do pipeline rollers work?

Pipeline rollers are an essential tool used in the installation and maintenance of pipelines. They provide a stable and smooth surface for the pipeline to roll across, which helps reduce friction between the pipeline and the ground, preventing damage to it as it is transported. They are typically placed at specific intervals along a longer pipeline for maximum support.

Are there any specific safety measures to followed when using pipeline rollers?

Yes, there are safety measures and requirements that must be followed when using pipeline rollers and it is crucial to follow the manufactures instructions before using the heavy duty pipeline roller. However, there are some measures that are important to follow no matter what model you are using. Always wear protective gear when operating the equipment and make sure that the machine is firmly secured before starting it up. Do not overload the roller beyond its maximum load capacity as this could cause damage to the unit or put workers in danger. Most importantly, never leave any tools or machinery on the pipeline while working on it since this can lead to unexpected movement of pipes during operation.

What is the expected lifespan of pipeline rollers?

Our pipeline rollers are constructed with high-quality materials to ensure their durability. Under normal usage and regular maintenance, our pipeline cradles are expected to last for many years. However, several factors can impact the lifespan of the product, such as its exposure to extreme temperatures, weather events, and corrosive materials. Proper use and maintenance of the rollers can also extend its lifespan and ensure optimal performance. Regular cleaning, inspection, and repair as needed can help to prevent wear and tear and extend the life of the pipeline rollers.

Side-By-Side Pipeline Rollers Comparison

|

Specifications |

|||||

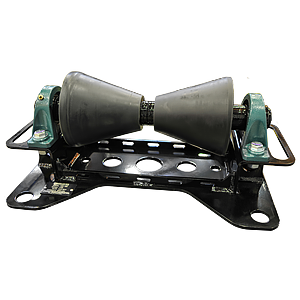

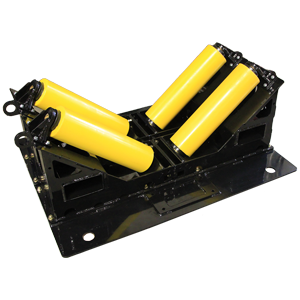

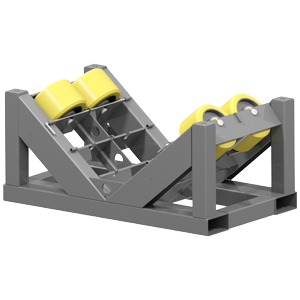

| Loading Capacity | 2,000 lbs (1-ton) | 10,000 lbs (5-ton) | 20,000 lbs (10-ton) | 40,000 lbs (20-ton) | 80,000 lb (40-ton) |

| Footprint | 16-¾” x 26-¾” x 9-9/16” | 30” x 60-⅜” x 22-5/16 | 43” x 60-⅜” x 22-5/16” | 33” x 57-⅜” x 27-⅛” | 58” x 71-1/2” x 31-11/16” |

| Diameter Range | 2" – 24" | 12” - 48” (Smaller sizes suitable with center roller option) | 12” - 48” (Smaller sizes suitable with center roller option) | 8” – 60” | 4" – 72" |

| Rolling Surface | Conical style 7-½” OD Urethane roller (x2) | V-style roller mounting, 6-1/4” OD Urethane side rollers (x4), optional: HZM5-220 center roller | V-style roller mounting, 6-1/4” OD Urethane side rollers (x4), optional: HZM5-220 center roller | V-style roller mounting, 11-½” OD Urethane side rollers (x4), optional: HZM405-179 horizontal roller | V-style roller mounting, 11-½” OD Urethane side rollers (x8), optional: HZM405-179 horizontal roller |

| Weight | 90 lbs | 600 lbs | 1,100 lbs | 900 lbs | 2,000 lbs |