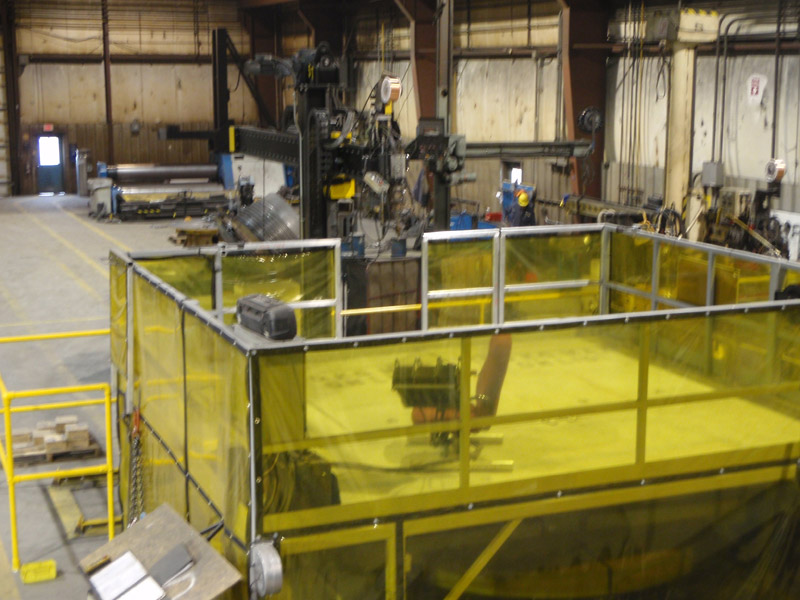

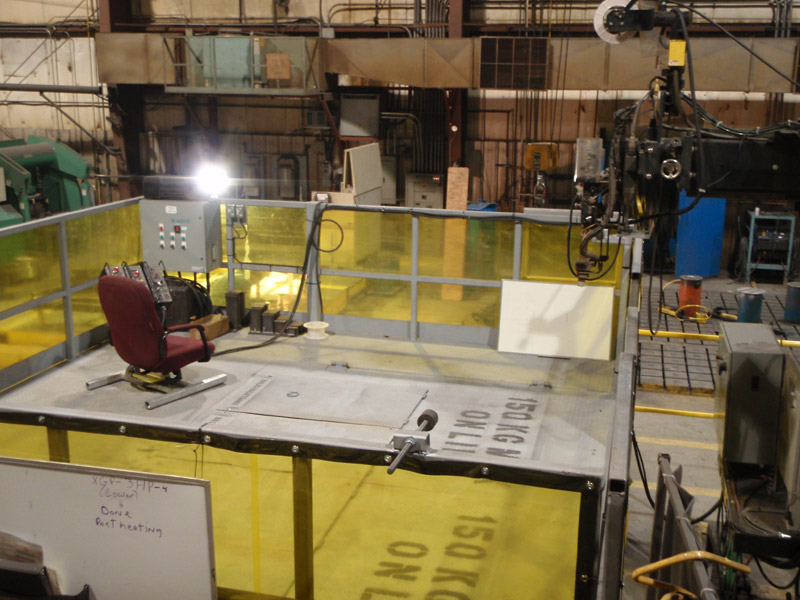

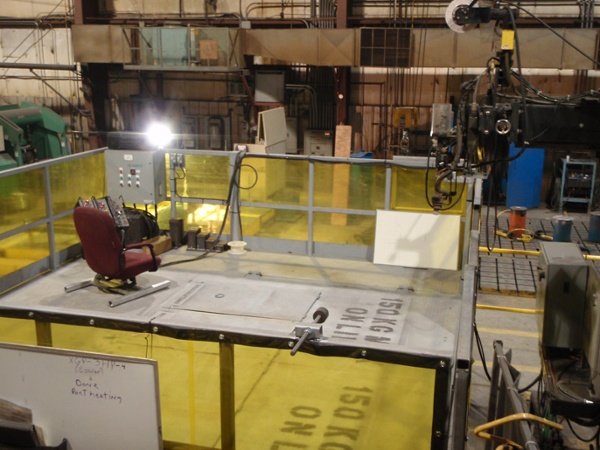

CASE STUDY: WELDING CELL FOR WIND TOWER COMPONENTS Saskatchewan, Canada

Project:

Customer required a heavy duty, integrated narrow gap welding cell for the fabrication of wind turbine components

The LJ Welding Solution:

A fully customized welding cell with 9 ft boom and column manipulator that allowed for mounting of existing welding head and integrated with a 9 ft x 20 ton capacity precision heavy duty turntable. Encoder feedback allows for control to 3 digits, and countless custom features including limit sensing included in package.

The Result:

Within 10 weeks of order, complete design and build of the sophisticated welding cell was completed. Customer has reported excellent results and complete satisfaction with the equipment.