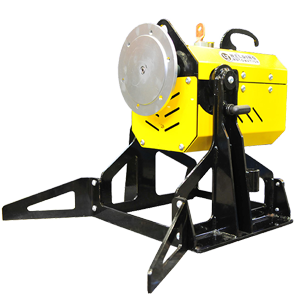

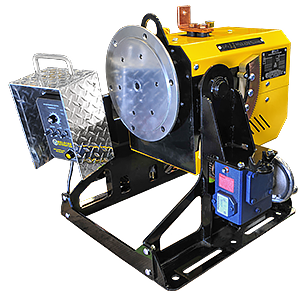

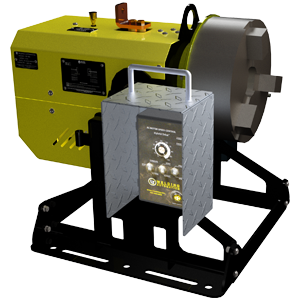

BENCH TOP WELDING POSITIONERS

- All LJ Welding's bench top positioners are built with powered variable-speed rotation in either direction and controlled by a variety of remote foot switch options.

|

Comfortable Welding: Our bench top positioners allow the operator to make down-hand welds for fast, smooth welding as well as to deposit more metal with fewer passes. |

|

|

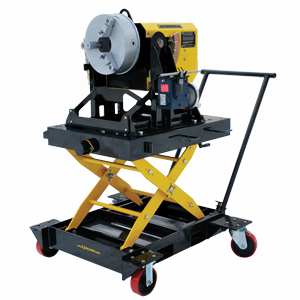

Increased Productivity: Our versatile thru-bore portable weld positioner are built to enhance productivity in lighter duty fabrication tasks in your welding shop |

|

|

Versatility: LJ’s bench top positioners come in useful for grinding, chipping or other welding applications that depend upon circular movements |

|

|

Safety: The equipment has been built with consideration of the end user’s safety, comfort and convenience in mind. |

WHAT ARE BENCH TOP WELDING POSITIONERS?

Benchtop positioners are essential in welding and fabrication projects. Here at LJ Welding, we offer a range of high-quality benchtop positioners. This equipment is designed to make welding more efficient and safer by allowing you to easily rotate and tilt your workpiece, with powered variable-speed rotation in both directions, which is easily adjusted via the included remote foot switch control, providing access to all angles without the need for manual repositioning. This makes down-hand welding fast and smooth, saving you time and money.

Benchtop positioners can be used in a wide range of industries, including aerospace, automotive, construction, and more. They are especially useful for applications where precision and accuracy are crucial, such as when welding pipes, tubes, or like-sized components. It's great for grinding, chipping or other welding applications that require circular movement. By using a benchtop positioner, you can save time and improve quality, resulting in reduced labor costs, higher productivity, and better end results.

Easily portable, small footprint and and user friendly controls

By allowing you to easily position your workpiece for optimal access, you can improve your level of control over the welding process, resulting in more accurate and uniform welds. Our benchtop positioners eliminate the need for manual repositioning, reducing worker fatigue and risk of injury. These machines also help to ensure consistency across multiple welds, resulting in better quality control and reduced material waste. So why wait? Invest in a benchtop positioner today and take your welding to the next level!

Interested in our Bench Top Positioners? Contact Us Today!

BENCH TOP WELDING POSITIONERS SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT BENCH TOP POSITIONERS

What is the load capacity for bench top positioners?

The weight capacity for bench top positioners varies depending on the model. At LJ Welding, we offer bench top positioners with weight capacities ranging from 300 lbs to 1000 lbs (136kg to 453kg)

What is the difference between powered and manual bench top positioners?

Powered bench top positioners use a motor and remote control to adjust the position of the workpiece, while manual bench top positioners require the user to adjust the position by hand. Powered bench top positioners are more efficient and allow for greater precision, while manual positioners require more physical exertion and may be less precise.

Can the rotation speed be adjusted on a bench top positioner?

Yes, the rotation speed can be adjusted on most bench top positioners. We offer bench top positioners with variable-speed rotation and remote control options, allowing for customization based on the unique needs of each project.

What is the maximum tilt angle for bench top positioners?

The maximum tilt angle for bench top positioners varies by model, but we offer bench top positioners with tilt angles ranging from -5 to 105 degrees.

Do bench top positioners require any special maintenance?

Bench top positioners require regular maintenance to ensure optimal performance and prolong their lifespan. This includes cleaning, inspection of moving parts, lubrication of bearings and gearboxes, and replacement of worn or damaged components as needed.

Are bench top positioners suitable for both small and large-scale welding projects?

Yes, bench top positioners can be used for both small and large-scale welding projects. They are ideal for applications where precision and accuracy are crucial, such as when welding pipes, tubes, or like-sized components.

Side-By-Side Bench Top Welding Positioners Comparison

| Positioner Specifications | |||

| Loading Capacity | 300 lbs (at mounting plate) | 1,000 lbs (at mounting plate) | 1,000 lbs (at mounting plate) |

| Footprint | 26-½” x 23-15/16” x 20-⅝” | 26-9/16” x 27-½” x 25-¼” | 26-9/16” x 27-½” x 25-¼” |

| Tilting Range | -15° – 105° (vertical mounting plate datum), Adjustable in 15° increments | -5° – 100° | -5° – 100° |

| Tilting Torque | 750 in-lbs | 3,000 in-lbs | 3,000 in-lbs |

| Turning Speed | 0.7 – 7 RPM | 0.5 – 5 RPM | 0.45 – 4.5 RPM |

| Mounting Plate Diameter | 8-½” (custom options available upon request) | 12-¾” (optional: 12” chuck/welding gripper) | 12-¾” (optional: 12” chuck/welding gripper) |

| Power Requirements | 120V, 3A, 1-ph, 60Hz | 120V, 9A, 1-ph, 60Hz | 120V, 9A, 1-ph, 60Hz |

| Ground Capacity | 200 Amps | 800 Amps | 200 Amps |

| Weight | 110 lbs | 280 lbs | 300lbs (without a 3 jaw chuck) |

| Thru-Bore | 3/8" hollow spindle (air purge fitting) | 3/4" hollow spindle (air purge fitting) | 3" hollow thru-bore |

.png?width=100&height=100&name=08P-200-thumb-300%20(1).png)