- Products

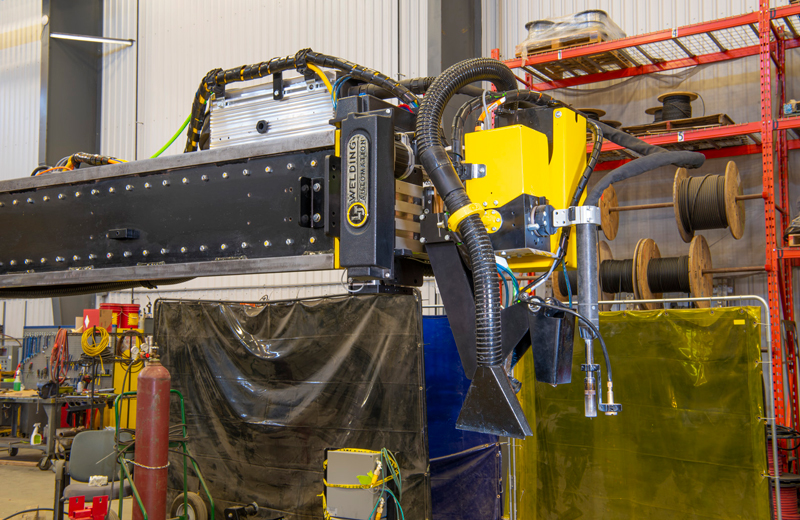

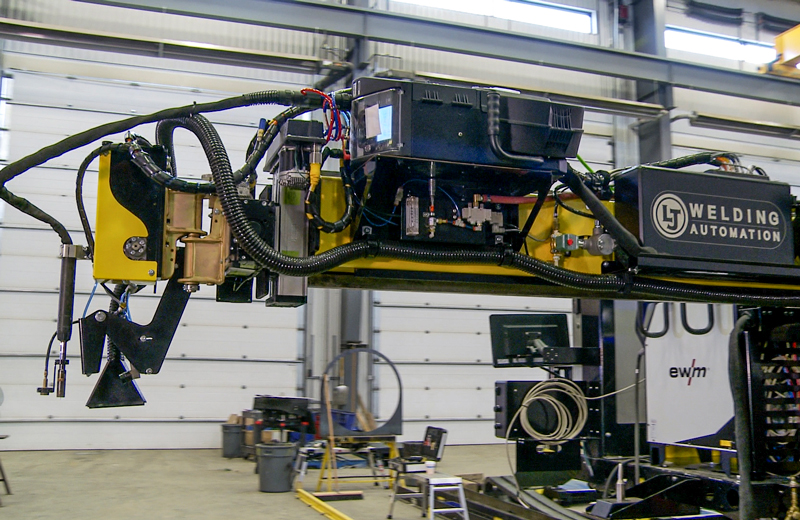

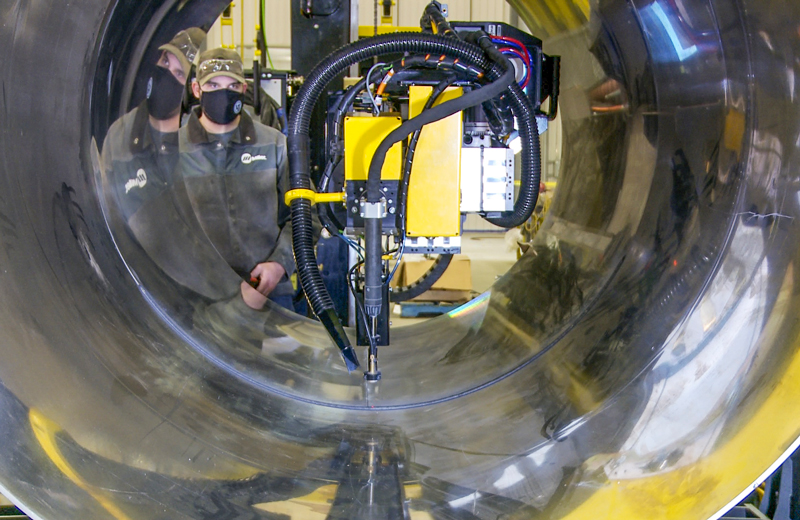

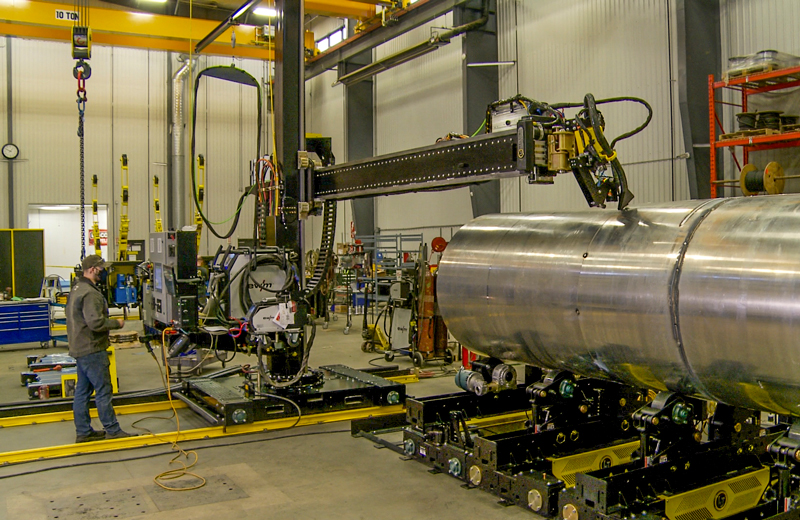

- Manipulators

- Pipe Titan Welding System

- Welding & Cutting Cobot

- Turning Rolls

- Pipe Stands

- Positioners

- Gear Tilt Positioners

- Pipe Turning Positioners

- 3,000 lbs Pipe Welding Positioner 16P-700

- 5,400 lbs Pipe Welding Positioner 30P-200

- 3,000 lbs Pipe Turning Positioner P3PS-100

- 6,000 lbs Pipe Turning Positioner P6PS-100

- 12,000 lbs Pipe Welding Positioner P12PS-100

- 24,000 lbs Pipe Welding Positioner P24PS-200

- 60,000 lbs Pipe Welding Positioner P60PS-200

- Height, Tilt & Rotate Positioner

- Headstock Tailstock Positioners

- Benchtop Positioners

- Low Profile Welding Turntables

- Welding Positioner Accessories

- Cable Reel Rollers

- Beam Clamp Rollers

- Pipe Lifting Jacks

- Pipeline Roller Equipment

- Pipe Hangers

- Clearance

- Promo Gear

- Rentals

- Videos

- Industry Applications

- Express Quote Request

- Products

- Manipulators

- Pipe Titan Welding System

- Welding & Cutting Cobot

- Turning Rolls

- Pipe Stands

- Positioners

- Gear Tilt Positioners

- Pipe Turning Positioners

- 3,000 lbs Pipe Welding Positioner 16P-700

- 5,400 lbs Pipe Welding Positioner 30P-200

- 3,000 lbs Pipe Turning Positioner P3PS-100

- 6,000 lbs Pipe Turning Positioner P6PS-100

- 12,000 lbs Pipe Welding Positioner P12PS-100

- 24,000 lbs Pipe Welding Positioner P24PS-200

- 60,000 lbs Pipe Welding Positioner P60PS-200

- Height, Tilt & Rotate Positioner

- Headstock Tailstock Positioners

- Benchtop Positioners

- Low Profile Welding Turntables

- Welding Positioner Accessories

- Cable Reel Rollers

- Beam Clamp Rollers

- Pipe Lifting Jacks

- Pipeline Roller Equipment

- Pipe Hangers

- Clearance

- Promo Gear

- Rentals

- Videos

- Industry Applications

- Express Quote Request