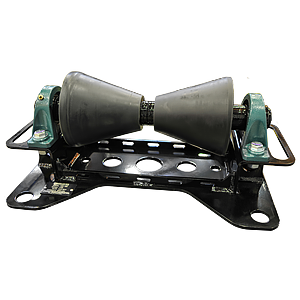

PIPELINE ROLLER EQUIPMENT

- Pipeline roller equipment helps to support and guide a pipeline section while allowing it to traverse river crossings or roads with minimal resistance. It provides reliable protection during the installation process, ensuring your pipelines are handled safely and efficiently.

| Modular Design: LJ's pipeline rollers offer a modular design that enables even the most complex of curved pulls to be achieved. Thanks to its lightweight construction, it can easily be transported with basic lifting equipment like chains, straps or forks. | |

| Worker Ergonomics: Our pipeline roller equipment provides operators with the ease, convenience and time savings of effortless handling and rolling - ultimately reducing strain on employees | |

| Increased Productivity: LJ’s pipeline roller equipment enables sites to operate with enhanced efficiency and speed, unlocking greater productivity and more rewarding profitability | |

| Smooth Rolling: Our equipment allows for reliable transport of piping, ensuring that it safely skirt any potential hazards at ground level and remain undamaged |

WHAT IS PIPELINE ROLLER EQUIPMENT?

LJ Weldings pipeline roller equipment are essential tools used in pipeline installations to facilitate the transportation and movement of heavy pipes. These rollers are lightweight and designed to support the pipes throughout the construction process, ensuring that they are safely transported from one point to another, regardless of the terrain or location. With our equipment our customers minimize the amount of friction and resistance, reducing the risk of damage or deformation on the pipes.

Our pipeline equipment is long lasting, made from high-quality materials, therefore capable of withstanding heavy loads of up to 80,000 lbs (40 tons). They are divided in two types - pipeline rollers and pipeline cranes. Each of these options come in a range of designs to suit different pipe sizes, weights, and diameters, and can be customized to fit specific project requirements.

Optimize pipeline installation process & enhance safety...

More importantly, our equipment can help you speed up the installation process of your pipelines, which enables you to complete your projects faster, saving you time and money.

Not only that but, at LJ Welding we prioritize safety and ensure that our equipment minimizes accidents, injuries, and harm to equipment and property. They are also easy to operate and maintain, requiring minimal effort and resources to keep them in good working condition.

Interested in our Pipeline Roller Equipment? Contact Us Today!

PIPELINE ROLLER EQUIPMENT SELECTION

FREQUENTLY ASKED QUESTIONS ABOUT PIPELINE ROLLER EQUIPMENT

What maintenance is required for pipeline rollers?

It is important to keep pipeline rollers in good working condition and to ensure their longevity. Although the specific maintenance requirements may vary depending on the type, model and usage circumstances, there are some common maintenance steps. Pipeline rollers should be cleaned regularly to remove any dirt or other contaminants that could damage the rollers or the pipeline. In addition, they should be inspected regularly for any signs of wear or damage, including checking the rollers for cracks, dents, or other deformities, as well as checking the bearings and other moving parts for wear. Another important step is lubricating the parts that require it to function properly and lastly when the equipment is not in use, it should be stored in a clean, dry, and secure location . If any damage is found during inspection, it is important to have the pipeline rollers repaired as soon as possible to prevent further damage or safety hazards.

What environments can pipeline rollers and cradles be used in?

Pipeline installation equipment can be used in a variety of settings, including both indoor and outdoor. The specific environments in which pipeline rollers can be used may depend on the type and model of the roller, as well as the materials from which it is made. However, there are common environments where pipeline rollers can be used like construction sites, industrial facilities, offshore locations or even environments with extreme temperatures. They can typically be used in flat and uneven terrain, making them a great tool for pipeline installation and maintenance projects

How many pipeline rollers are typically used in an installation project?

The number of pipeline rollers used in an installation project depends on a number of factors such as the size, length, diameter or weight of the pipeline being transported. In general, multiple pipeline rollers are used to support the pipeline during the installation.