MN12-200: 12' X 12' COLUMN AND BOOM WELDING MANIPULATOR

Our manipulators, including MN12-200, play a significant role in the automated welding processes of large vessels and other workpieces. Automatic welding heads (typically submerged arc) are designed to be mounted on a stiff and nearly vibrationless boom and moved to the desired height with powered columns.

LJ’s MN12-200 comes with a modular construction that ensures 360-degrees radial accessibility to welding heads, covering vast areas in the shop. It is ideal for hard automation welding solutions and offers an advanced user interface that is easy to use. MN12-200 is a crucial tool for applications that involve automated welding of pipes and vessels. Moreover, MN12-300 maximizes productivity and efficiency. Lastly, it also reduces rework and scrap, and the final results aren't dependable on the skills of the operator since the whole process is automated.

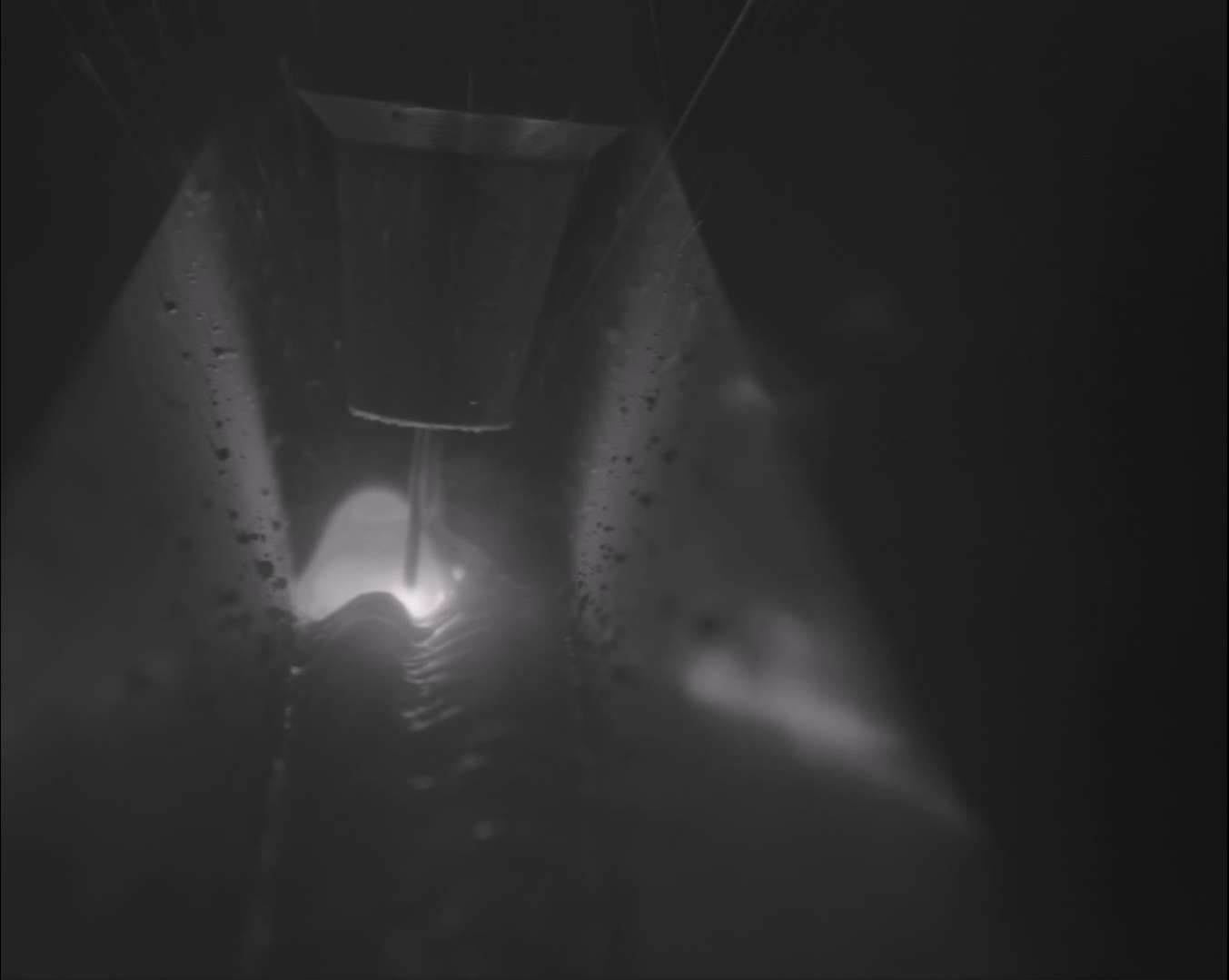

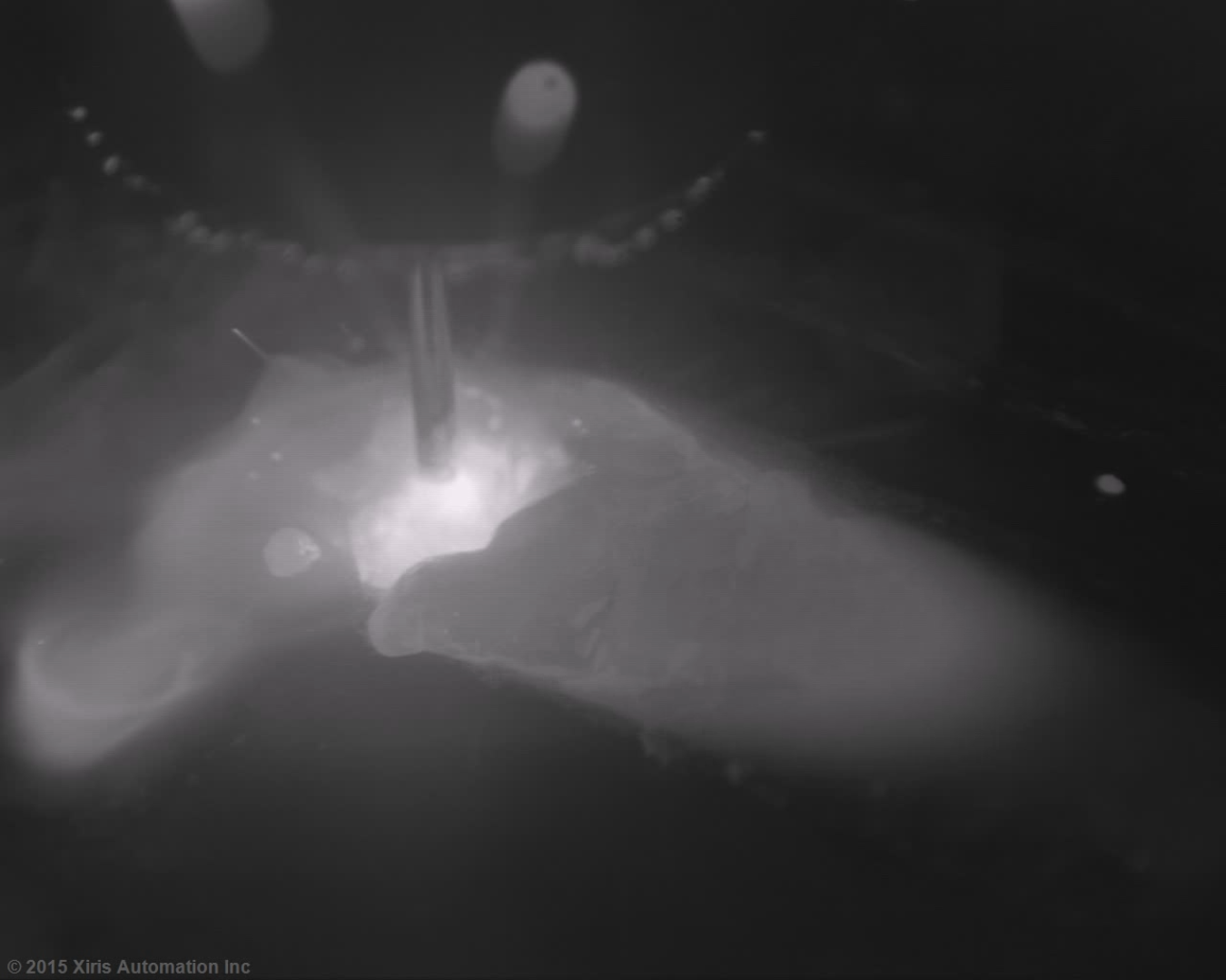

Our MN12-300 has a loading capacity of 500 lbs at boom end, boom stroke of 132" and column stroke of 144". This machine has built-in column/boom welding seam trackers with laser vision tracking and a laser sensor. It also has camera systems that monitor and record all open arc welding processes including MIG, MAG, TIG, Plasma, laser and stick welding. We also offer a wide selection of accessories and options available depending on the customer's request and need. As far as the welding source options are concerned, we offer submerged arc (SAW), MIG, or a solution to customer’s specification. We also offer control upgrades including full integration to LJ welding positioners or turning rolls through HMI touchscreens and master PLC.

Looking for a welding positioner with different technical parameters? Make sure to check out our MNC4-100, MNP-600, MN6-100, MN9-300, or MN16-100.

| Load Capacity (at boom end) | 500 lbs |

| Boom Stroke | 132" |

| Column Stroke | 144" |

| Boom Traverse Speed Range | 5–120 in/min |

| Mast Traverse Speed Range | 5–120 in/min |

| Travel Car Speed | 5–120 in/min |

| Power Requirements | 480 V, 3-ph |

| Equipment Mass | Variable |

| Options |

Welding Power Source Options: Submerged Arc (SAW), MIG, or to customer specification Customizable with full integration capabilities for most existing mainstream welding equipment |

, MAG, TIG, Plasma, Laser and Stick welding. Processes can be viewed remotely (40 m / 130 ft. away), providing live images of the torch, weld area and material during standard and high-power welding conditions.

, MAG, TIG, Plasma, Laser and Stick welding. Processes can be viewed remotely (40 m / 130 ft. away), providing live images of the torch, weld area and material during standard and high-power welding conditions.

therefore some kind of physical feature is needed for the laser sensor to take measurements. In welding, a physical feature can be a gap, mismatch, an edge, etc. and depending on the sensor, even very small features (around 0.2mm) can be tracked. A comparison is made between the measured position of the feature and a pre-taught position and if there is a difference, correction co-ordinates are sent to the slides or to the controller positioning the robot to place the column boom weld manipulator torch correctly at the start of and during welding. This results in welds of higher quality that are always in the right place.

therefore some kind of physical feature is needed for the laser sensor to take measurements. In welding, a physical feature can be a gap, mismatch, an edge, etc. and depending on the sensor, even very small features (around 0.2mm) can be tracked. A comparison is made between the measured position of the feature and a pre-taught position and if there is a difference, correction co-ordinates are sent to the slides or to the controller positioning the robot to place the column boom weld manipulator torch correctly at the start of and during welding. This results in welds of higher quality that are always in the right place.