×

KEY SPECIFICATIONS

|

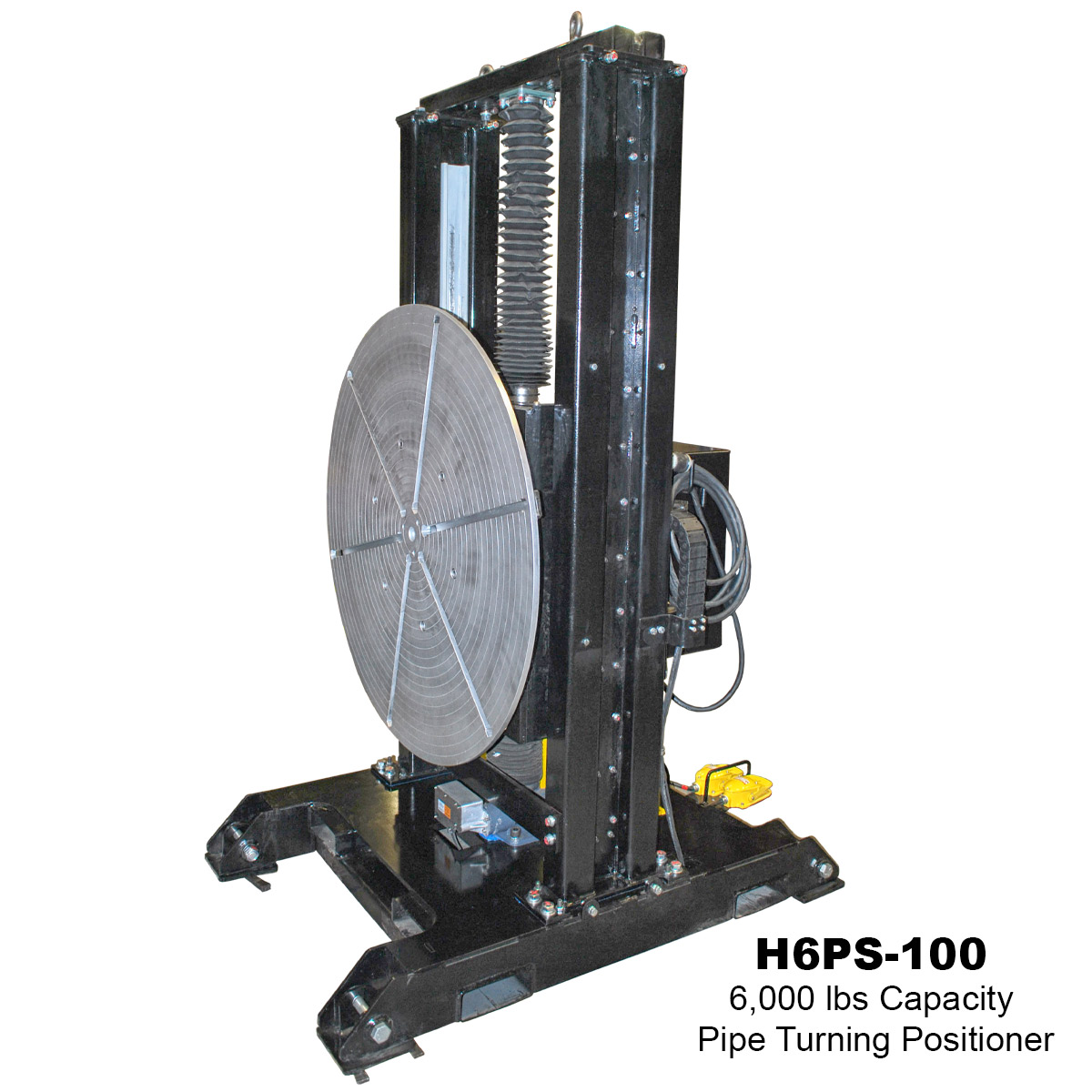

Loading Capacity |

6,000 lbs (at 12” overhung load) |

|

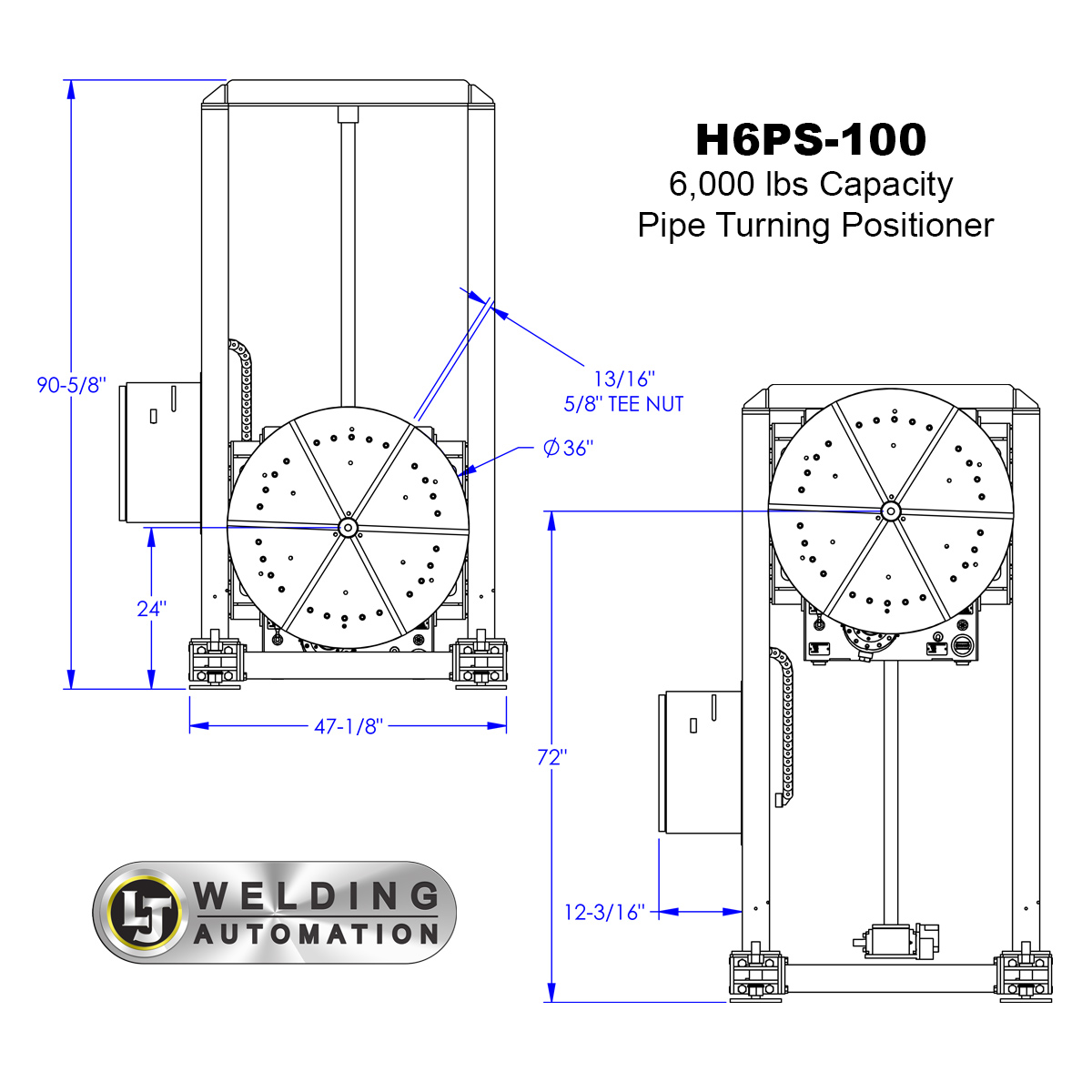

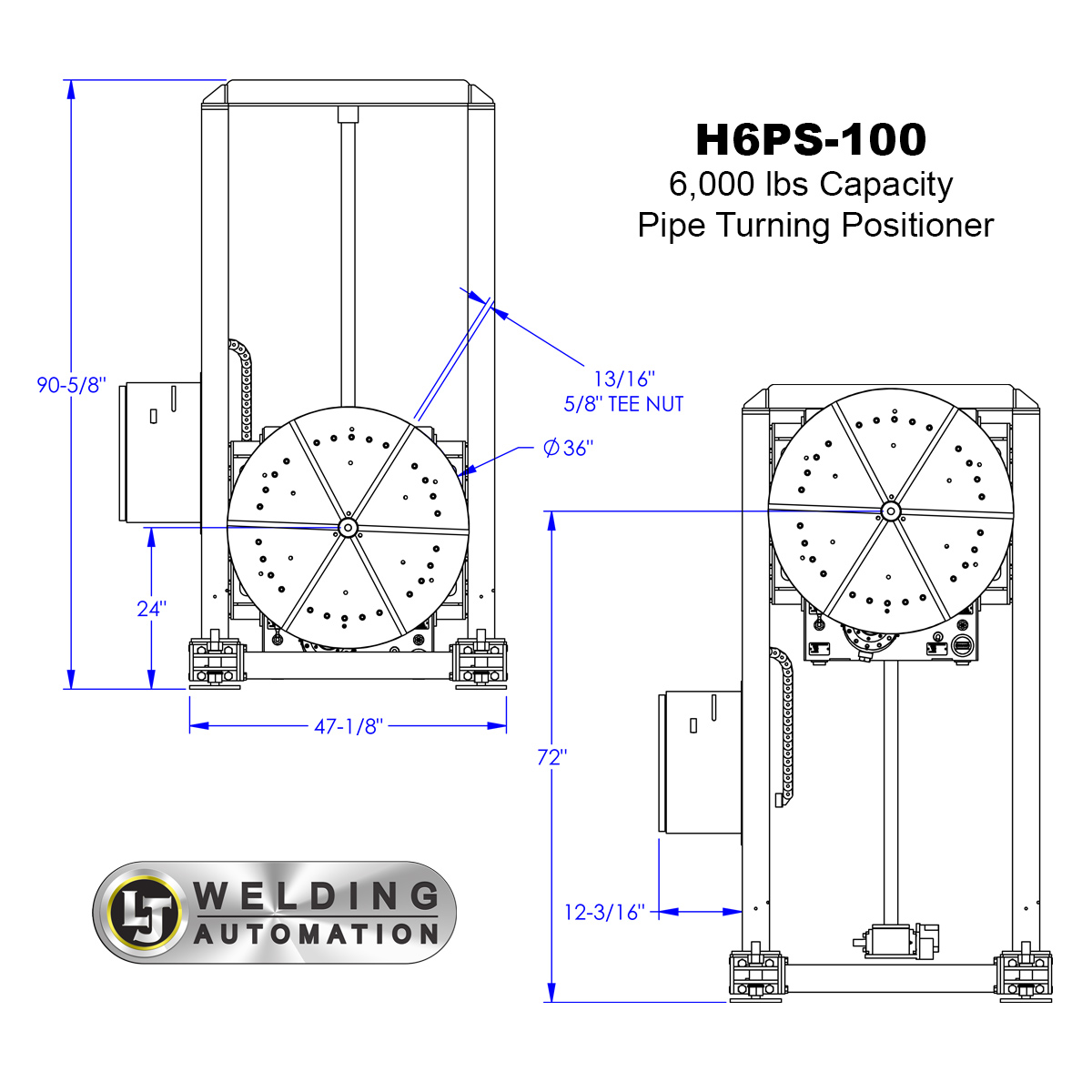

Footprint |

67-¼” x 53-⅞” x 91-9/16” |

|

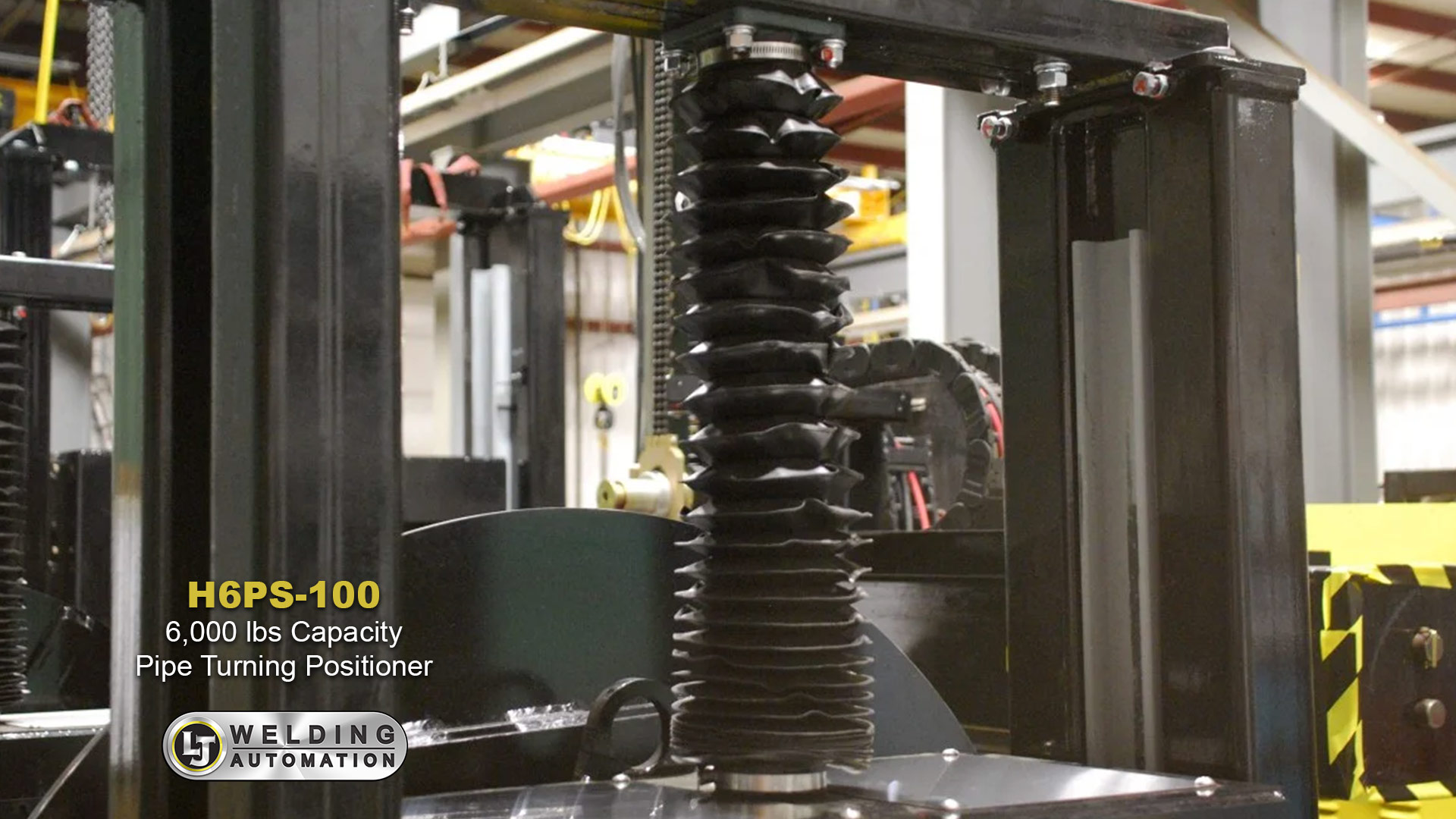

Turning Torque |

60,000 in-lbs |

|

Turning Speed |

0.1 - 2.5 RPM |

|

Height Range |

24” - 72” (at mounting plate) |

|

Lifting Speed |

3 - 30 ipm |

|

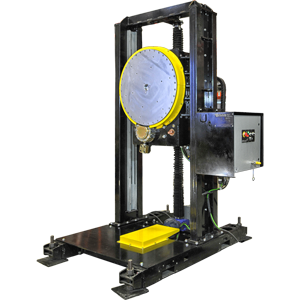

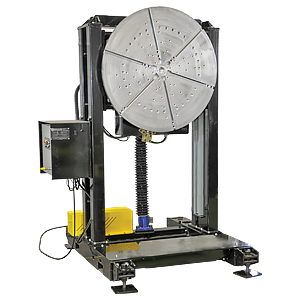

Mounting Plate Diameter |

42” (T-Slot Plate with 6 x 5/8" slots) |

|

Power Requirements |

480V, 5A, 3-ph, 60Hz |

|

Ground Capacity |

800 Amps |

|

Weight |

2,970 lbs |