hotspot1

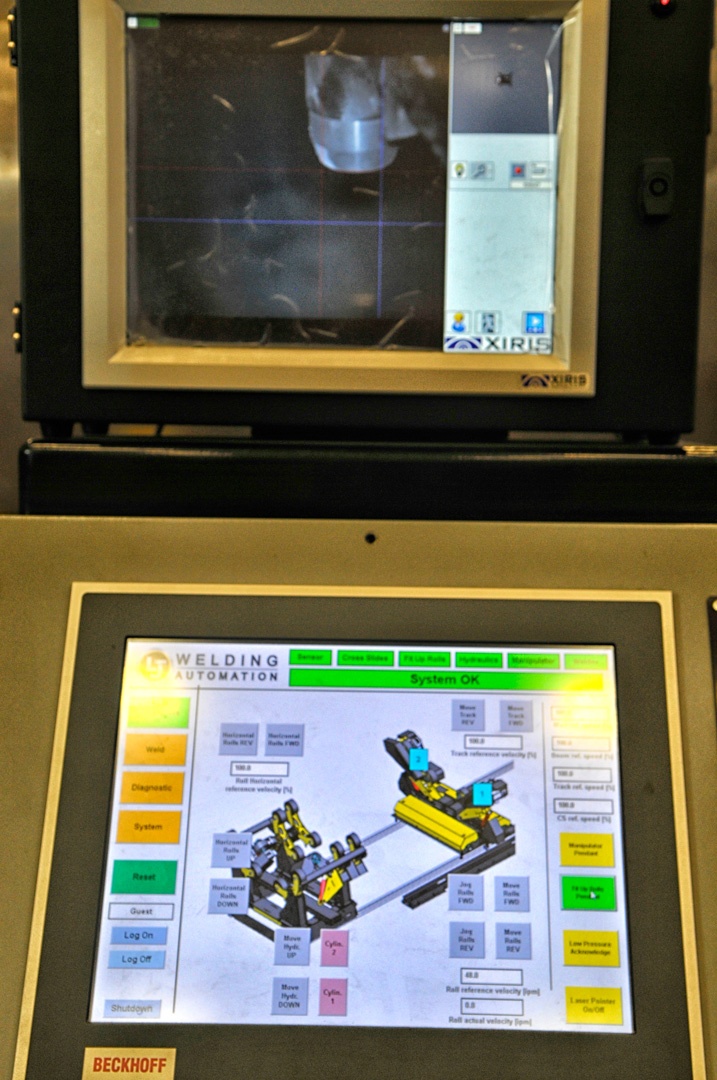

Camera Systems

Xiris XVC-O Weld Camera

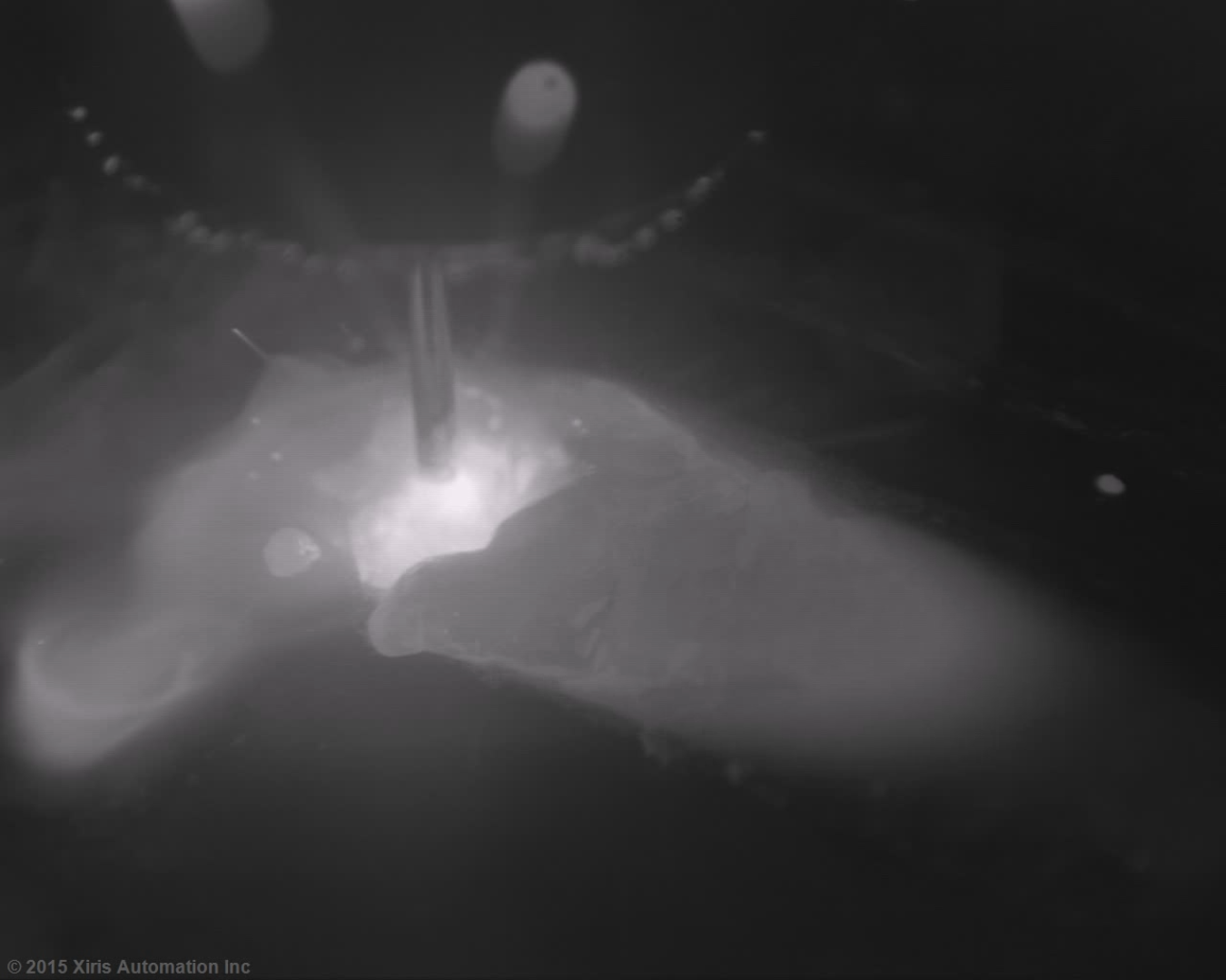

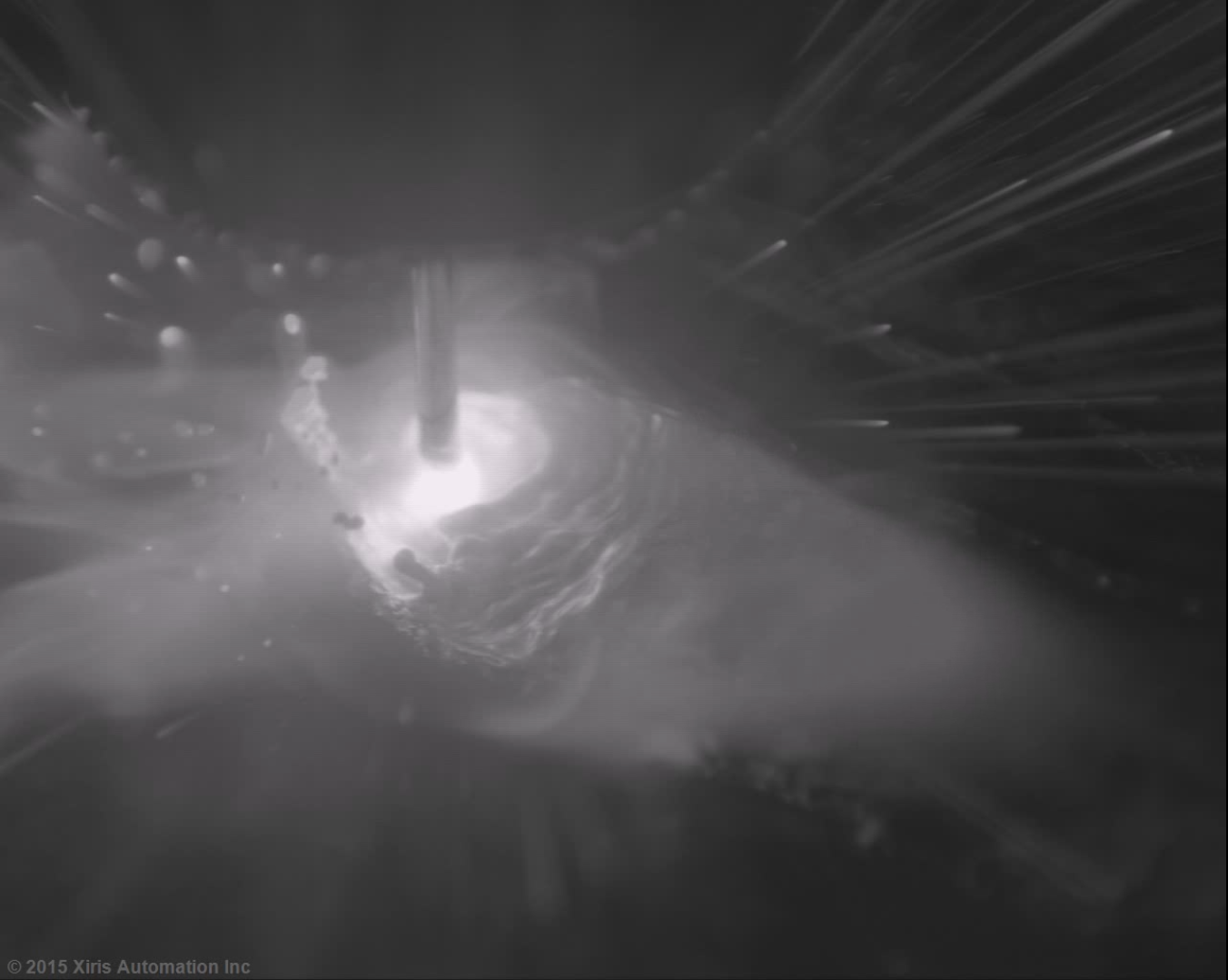

The Xiris XVC-O Weld Camera monitors and is capable of recording all open arc, welding processes including MIG, MAG, TIG, Plasma, Laser and Stick welding. Processes can be viewed remotely (40 m / 130 ft. away), providing live images of the torch, weld area and material during standard and high-power welding conditions.

XVC-S Weld Camera

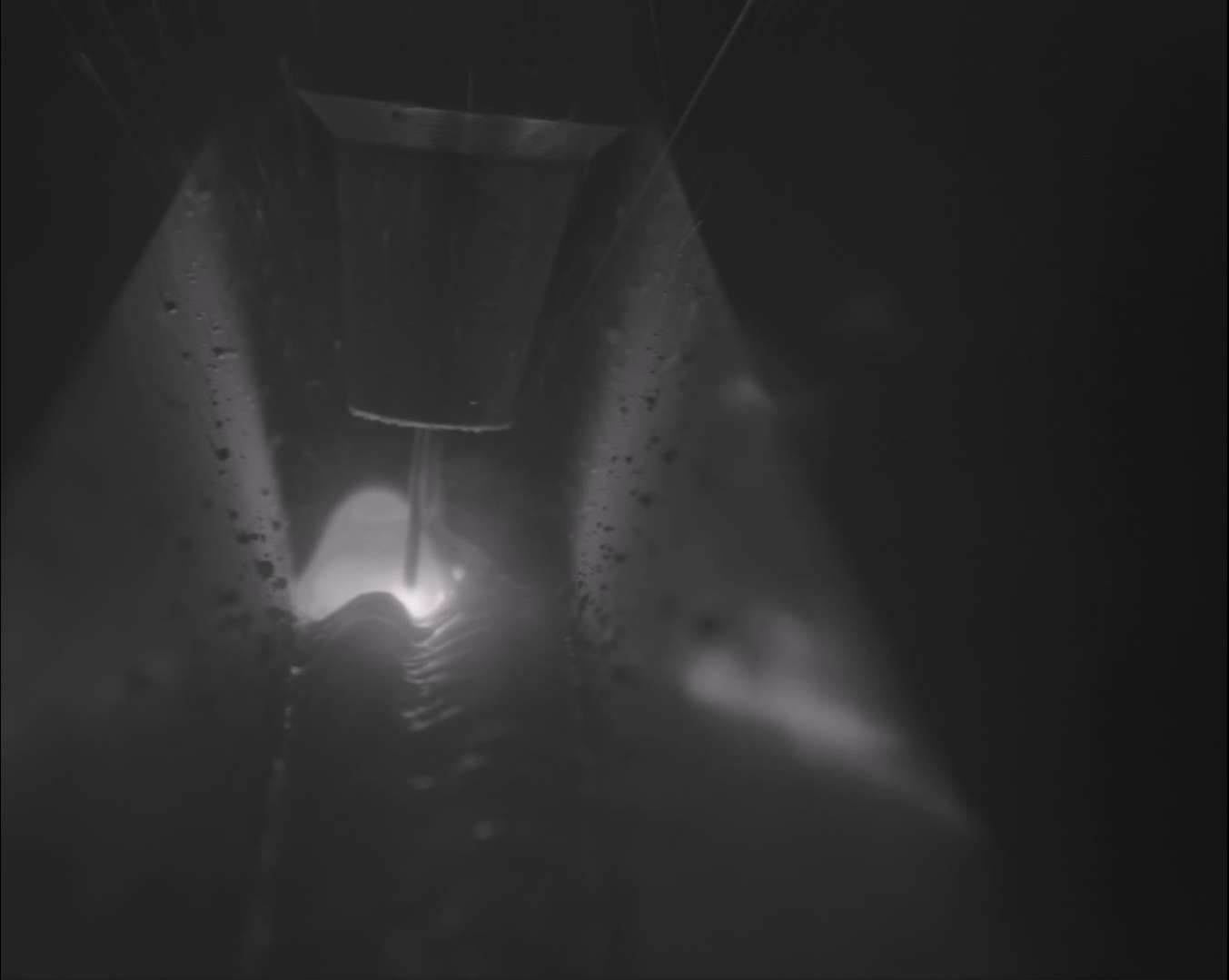

The XVC-S Weld Camera provides a real-time view of the torch when welding with submerged arc (SAW). It is particularly useful when placed on column and boom welding manipulators as it allows the operator to observe the weld area from ground level.

Housed in a rugged enclosure, the XVC-S features single or dual crosshairs and can act as a set-up tool to position the submerged arc torch. The visual feedback it provides to the operator can also be used as a means to adjust the position of the boom and column welding manipulator or parameters during the welding operations.

Tactile Seam Tracking

WHAT IS TACTILE SEAM TRACKING?

As the name suggests, tactile sensors physically contact the weld seam using a contact probe.

How Does Tactile Seam Tracking Work?

As the torch position changes relative to the workpiece, the probe deflects in the opposite direction and the controller makes adjustments to return the torch to its original position.

Benefits Of Tactile Seam Tracking

Tactile seam tracking systems are best suited for weld seams with large, distinct geometry. If the weld seam is too small, the probe can lose contact with the seam and run the welding torch off track.Tactile Seam Tracking Is Best Suited for the following:

- Welds that are the same basic shape and similar seam configuration with variations in size, lenght and width.

- Repetitive welding applications using the same weld part before retooling the welding station for the next part type.

- Pressure vessels, cylinders, tanks and other circumferential welding projects.

- Beam welding fabrication where operators manually weld beam or are required to manually reposition the torch for the full length.

- Single or multi-pass lap joints, fillet weld or v-groove seam configurations.

- Cylinder sag on large tank.

Laser Vision Seam Tracking

What Is Laser Vision Seam Tracking?

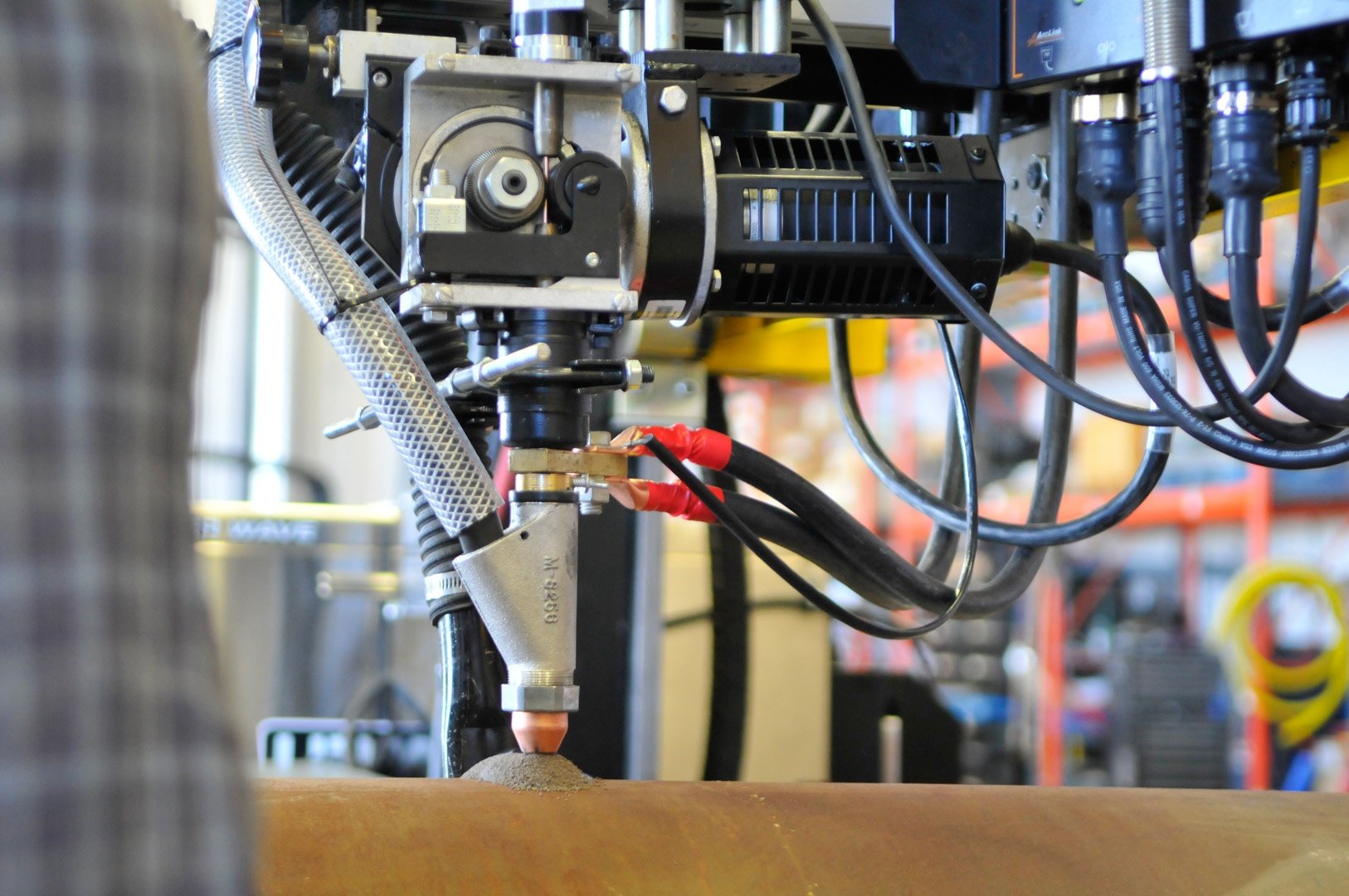

Laser Vision Seam tracking systems use a laser ribbon which is projected onto the surface of the part creating a distinct laser line across the weld seam. The laser line is then viewed at a slight angle using a camera. The resulting image is analysed to extract key reference points (such as the edges of the groove) that can then be used to measure and provide feedback for actuators. Once a reference point has been created, the controller will make any necessary movements to keep this reference point in the same position relative to the welding torch. Laser Vision systems have a very high resolution allowing them to reliably track both large and small weld seams.

Watch a column and boom manipulator use laser seam tracking on aluminum and steel below:

Flux Delivery

What Is A Flux Delivery System?

Flux delivery systems provide a means of moving flux from the column and boom manipulator platform to the weld head. A small pressure vessel is used to maintain positive pressure on the flux and aerate the flux so that it flows easily upwards to the welding torch.

How Does A Flux Delivery System Work?

Typically, flux is delivered to a flux hopper located at the weld head; however for systems where space is limited, flux can be delivered directly to the welding torch, eliminating the need for a flux hopper at the weld head.

What Flux Delivery Capacities Are Available?

Flux delivery systems come in 100lb and 300lb capacities. Heated delivery systems are available as well. Larger capacities help to reduce non-essential, non-arc time activity.

Flux Recovery & Storage

What Is A Flux Recovery System?

Flux recovery systems are used to capture unused flux so that it can be reused. Typically, 2 lbs of flux are required for every 1 lb of deposited weld; however, recovering flux can reduce this ratio to 1.25 lbs of flux per 1 lb of weld metal. Electric and pneumatic versions are available.

How Does A Flux Recovery System Work?

Electric flux recovery systems use an electric motor to create a vacuum strong enough to suck flux back into the flux hopper. Pneumatic recovery systems require shop air pressure and using a venturi-like device, compressed air is used to create a vacuum strong enough to suck flux back into the flux hopper. Heated flux hoppers are also available.

Boom Mounted Carriage Option

LJ offers an integrated powered cart option for customers' with limited shop floor space and demanding production schedules.

The key advantage to the integrated powered cart is that it allows the weld head to move laterally along the boom, rather than manipulating the boom with a weld head at the end.

The integrated powered cart option is most commonly used with LJ's MNP-600 portable column and boom welding manipulator.

Flux Delivery

What Is A Flux Delivery System?

Flux delivery systems provide a means of moving flux from the column and boom manipulator platform to the weld head. A small pressure vessel is used to maintain positive pressure on the flux and aerate the flux so that it flows easily upwards to the welding torch.

How Does A Flux Delivery System Work?

Typically, flux is delivered to a flux hopper located at the weld head; however for systems where space is limited, flux can be delivered directly to the welding torch, eliminating the need for a flux hopper at the weld head.

What Flux Delivery Capacities Are Available?

Flux delivery systems come in 100lb and 300lb capacities. Heated delivery systems are available as well. Larger capacities help to reduce non-essential, non-arc time activity.

Flux Recovery & Storage

What Is A Flux Recovery System?

Flux recovery systems are used to capture unused flux so that it can be reused. Typically, 2 lbs of flux are required for every 1 lb of deposited weld; however, recovering flux can reduce this ratio to 1.25 lbs of flux per 1 lb of weld metal. Electric and pneumatic versions are available.

How Does A Flux Recovery System Work?

Electric flux recovery systems use an electric motor to create a vacuum strong enough to suck flux back into the flux hopper. Pneumatic recovery systems require shop air pressure and using a venturi-like device, compressed air is used to create a vacuum strong enough to suck flux back into the flux hopper. Heated flux hoppers are also available.

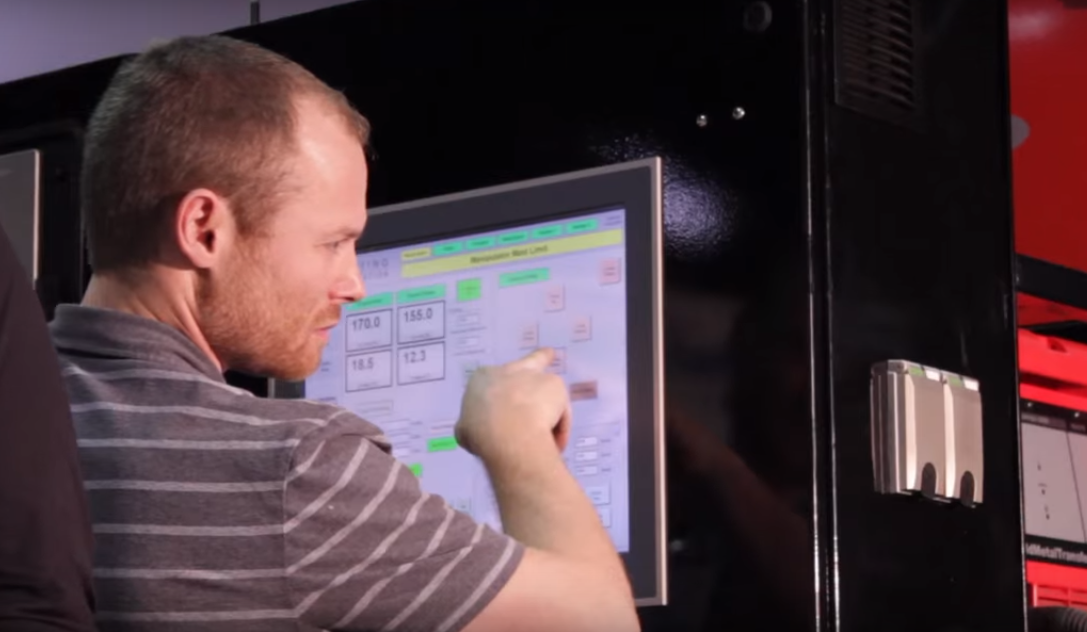

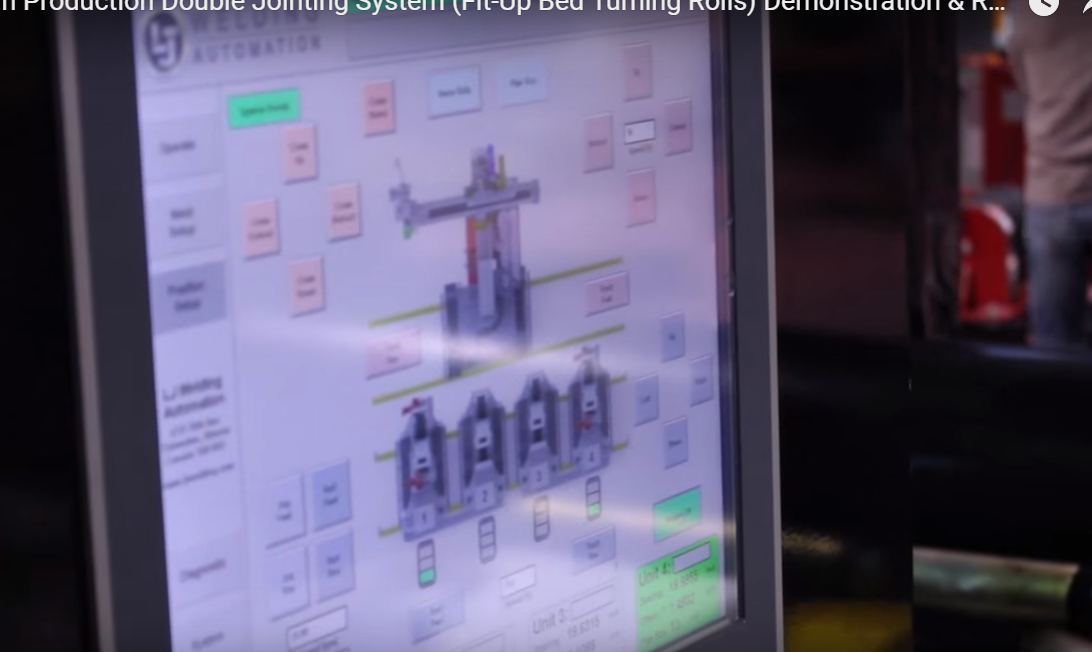

HMI Touch Screen Options

What Are HMI Touch Screen Controls?

HMI (Human machine interface) is the computer interface that communicates and commands all major functions of your welding manipulator or beam welding gantry system.

What Can the HMI Touch Screen Control?

- Rotation speed of rollers and positoners.

- Weld speed.

- Height adjustment (positioners if powered height adjust.)

- Welding controls.

- Camera.

- Seam tracking.

- Data Collection

How Do I know If I Should Choose HMI Controls For My Welding Application?

It will depend on the complexity of your welding application, scope and budget. If your application has many moving parts, such as seam tracking, welding turning rolls, a column and boom manipulator and camera, an HMI would streamline all variable factors into a simplified screen.

If you aren't integrating your CaB manipulator with any other material handling equipment, standard equipment controls are sufficient.

HMI Controls Further Reading

The HMI control is a PC based computer that is easy to set or change, store useful data for quality assurance purposes, and can fully integrate with all LJ Welding products. The HMI touchscreen panel controls all complex welding automation functions from one single location.

Welding Boom Mounted Controls

Boom mounted controls ensure the weld operator has direct sight of the weld in order to make the correct adjustments during welding if needed.

The welding boom mount controls allow the operator to:

- Controls flux delivery/recovery when integrated.

- Preprogram multiple weld settings (for repetitive welds).

- Control material handling systems if integrated with other LJ equipment.

- Manage seam tracking settings for laser or tactile.

- Control wire feed from boom.

- Control cross slides / weld head from boom.

Wireless Hand Pendant

For Productivity

LJ's wireless hand pendant gives the operator more mobility that the conventional cable wire version, reduced the likelihood of the operator getting tangled up in wired systems.

For Safety

and has a "deadman switch" or "e-stop" to respond quickly in an emergency situation. Additionally, the pendant with communicate to the system it's connected to switch off if it loses communication with the transmitter.

For Compatibility

The wireless hand pendant uses a 19pin connector found on nearly all of LJ's equipment.

Standard Hand Pendant

LJ's standard hand pendant comes with standard weld start, weld stop and wire feed, along with rotation for integrated material handling set-ups.

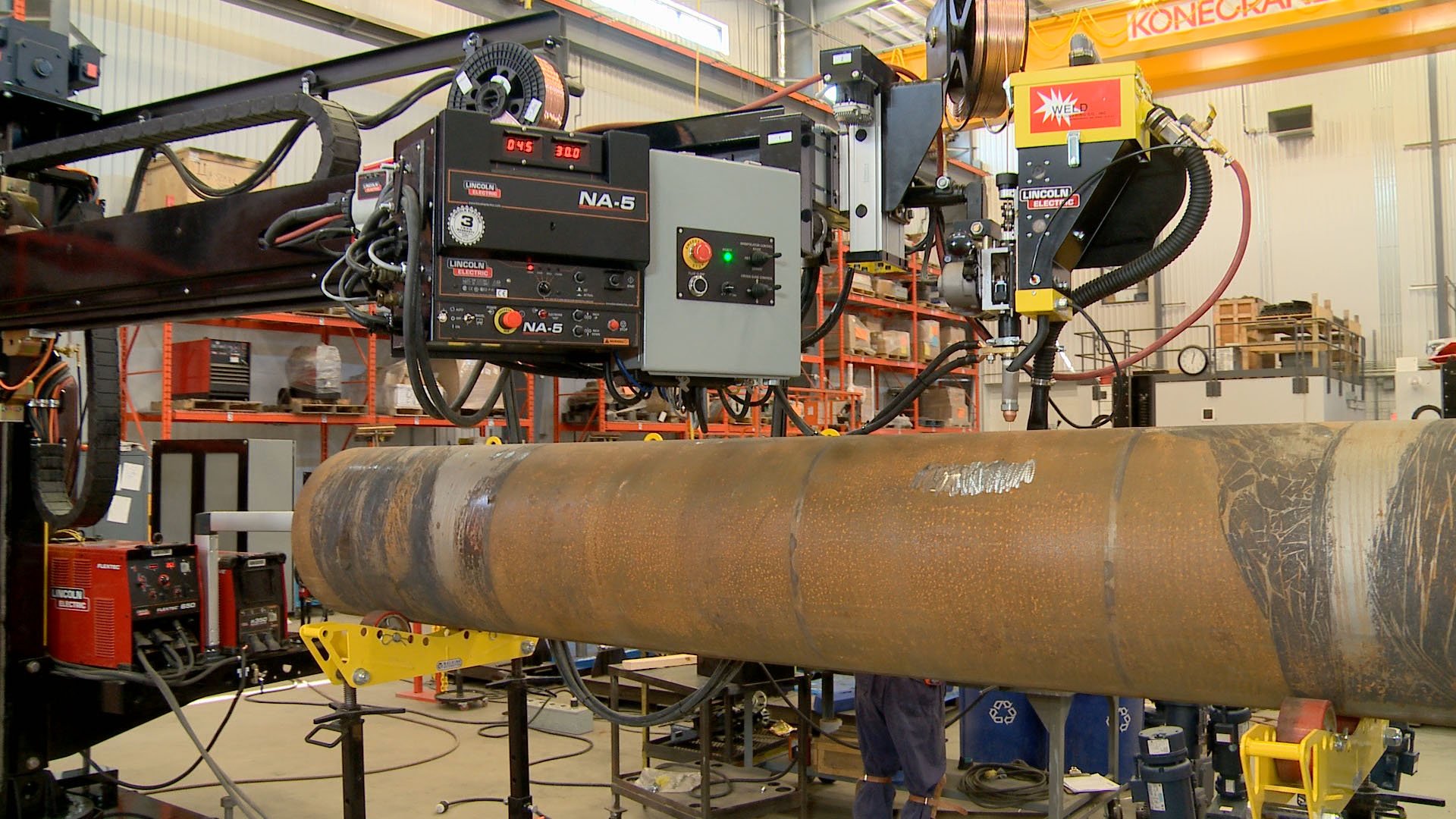

Submerged Arc Welding Options

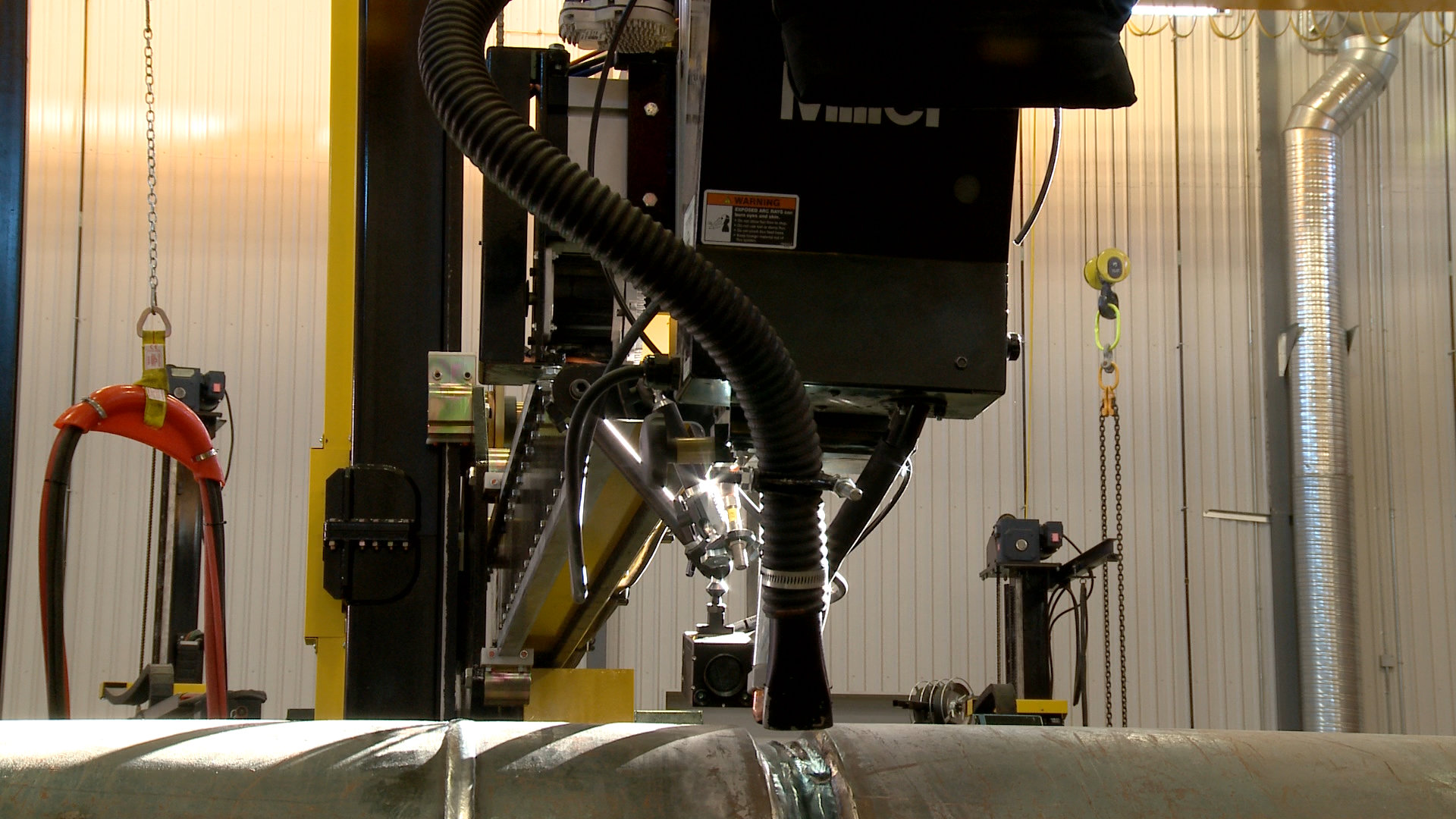

Column and Boom (CaB) welding manipulators are most commonly used for Submerged Arc Welding (subarc or SAW) applications; however, they can be used for GMAW or other open-arc applications as well. LJ can also integrate virtually any open or subarc system to column and boom manipulators.

Subarc welding’s most significant advantage is maximizing welding deposition rates, to rates that are 3-5x higher than other comparable processes. Deposition rates of 20-30lbs/hour (or more) can be achieved depending on the weld joint, consumables, and procedure. DC SAW power sources are only capable of supplying direct current to the electrode. Lincoln Electric's Idealarc DC-1000 and DC-1500 and Miller's Subarc 650, 800, 1000, and 1250 are all DC power sources that can all be readily integrated with LJ's welding manipulators.

AC/DC SAW power sources can weld at higher efficiencies, with lower power consumption, and can supply an alternating or square wave current to the electrode. Lincoln's Powerwave AC/DC 1000 and Miller's Subarc AC/DC Digital and AC/DC 1250 Digital are AC/DC power sources that can be readily integrated with LJ's column and boom welding manipulators. AC/DC power sources offer the benefits of variable wave form and the best characteristics of DC+ and DC- polarity.

Open Arc Welding Options

Power sources for open arc applications must be both powerful and welder-friendly. Miller’s XMT® 350 CC/CV, Dinse and XMT® 450 CC/CV 230/460 V start arcs and stick electrodes without contaminations and inclusions. The Dimension™ 650 is especially versatile, with a gouging mode that provides up to 800 amps of full power. Three wire modes make it ideal for GMAW, FCAW, or SAW applications.

User-friendly controls with common welding terminologies help mitigate errors. Miller’s Pipeworx 400 Welding System 230/460 V even allows welders to change between welding processes at the touch of a button. Wind technology provides cooling and protects components from dust and contaminants for maximum reliability. The fans run only on demand to save energy. All power sources can be used with spool guns and feeders, and are easy to integrate into LJ’s column and boom manipulators.

Flux Delivery

What Is A Flux Delivery System?

Flux delivery systems provide a means of moving flux from the column and boom manipulator platform to the weld head. A small pressure vessel is used to maintain positive pressure on the flux and aerate the flux so that it flows easily upwards to the welding torch.

How Does A Flux Delivery System Work?

Typically, flux is delivered to a flux hopper located at the weld head; however for systems where space is limited, flux can be delivered directly to the welding torch, eliminating the need for a flux hopper at the weld head.

What Flux Delivery Capacities Are Available?

Flux delivery systems come in 100lb and 300lb capacities. Heated delivery systems are available as well. Larger capacities help to reduce non-essential, non-arc time activity.

Flux Recovery & Storage

What Is A Flux Recovery System?

Flux recovery systems are used to capture unused flux so that it can be reused. Typically, 2 lbs of flux are required for every 1 lb of deposited weld; however, recovering flux can reduce this ratio to 1.25 lbs of flux per 1 lb of weld metal. Electric and pneumatic versions are available.

How Does A Flux Recovery System Work?

Electric flux recovery systems use an electric motor to create a vacuum strong enough to suck flux back into the flux hopper. Pneumatic recovery systems require shop air pressure and using a venturi-like device, compressed air is used to create a vacuum strong enough to suck flux back into the flux hopper. Heated flux hoppers are also available.

Standard Swivel Base Option

All LJ column and boom welding manipulators come standard with a 350° rotating swivel base and a swivel lock and can be either free standing or integrated with a rail car system. This allows for more agile job set-ups than a fixed base column and boom.

Rail Car System Installation Option

The rail track manipulator option is ideal for shops that require their manipulator weld head's movements on three axis (up & down, forward & reverse and along the workpiece).

The rail track option fully integrates with other track mounted equipment including tank turning rolls, pipe alignment rolls, vessel rotators and pipe rolls.

Rail installation and cable management can be quoted on request.

Wall Mounted Base Option

The wall mounted option is best suited when floor space is unavailable and the manipulator does not require a full 360º range of movement. The Boom Mounted Carriage option compliments the wall mounted base set-up because movement of the weld head can still be achieved on 2 axis.