CASE STUDY: PIPE WELDING POSITIONERS FOR PIPE SPOOLING Dubai, UAE

Project:

4″-30″ process pipe requires cost-effective weld positioning, rotation, and welding with ultimate end use in an LNG terminal.

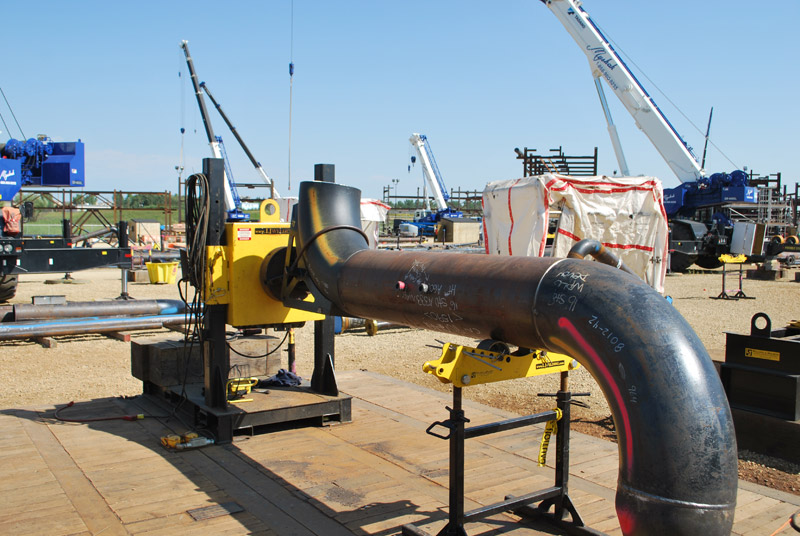

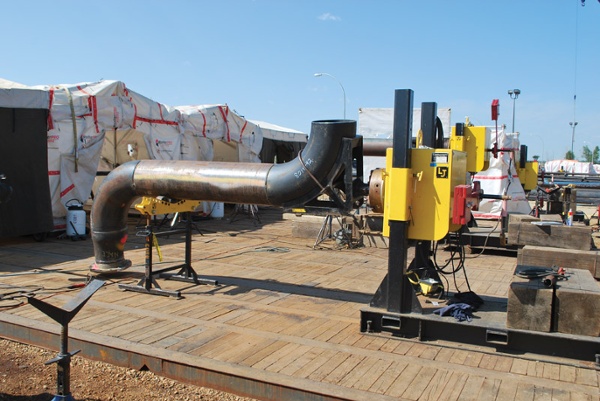

The LJ Welding Solution:

LJ supplied a combination of a pipe turning positioner—also known as a ‘spinner’—for economical and high torque rotation of process piping. The LJ pipe turner series has the key features of being the most economical weld positioners on the market, with very high torque output and large speed range for efficient weld positioning of any size pipe.

The Result:

The customer purchased an LJ pipe turning positioner for approximately one-third the price of a conventional welding positioner, with superior output specifications. The customer was able to significantly increase their pipe welding throughput, with plans to add additional LJ pipe turning positioners in the future.